Efficient three-phase slot-free permanent magnet motor

A permanent magnet motor, high-efficiency technology, used in synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the problems of low power density, low winding factor, temperature rise, etc. Winding factor, the effect of improving output torque and positioning accuracy, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

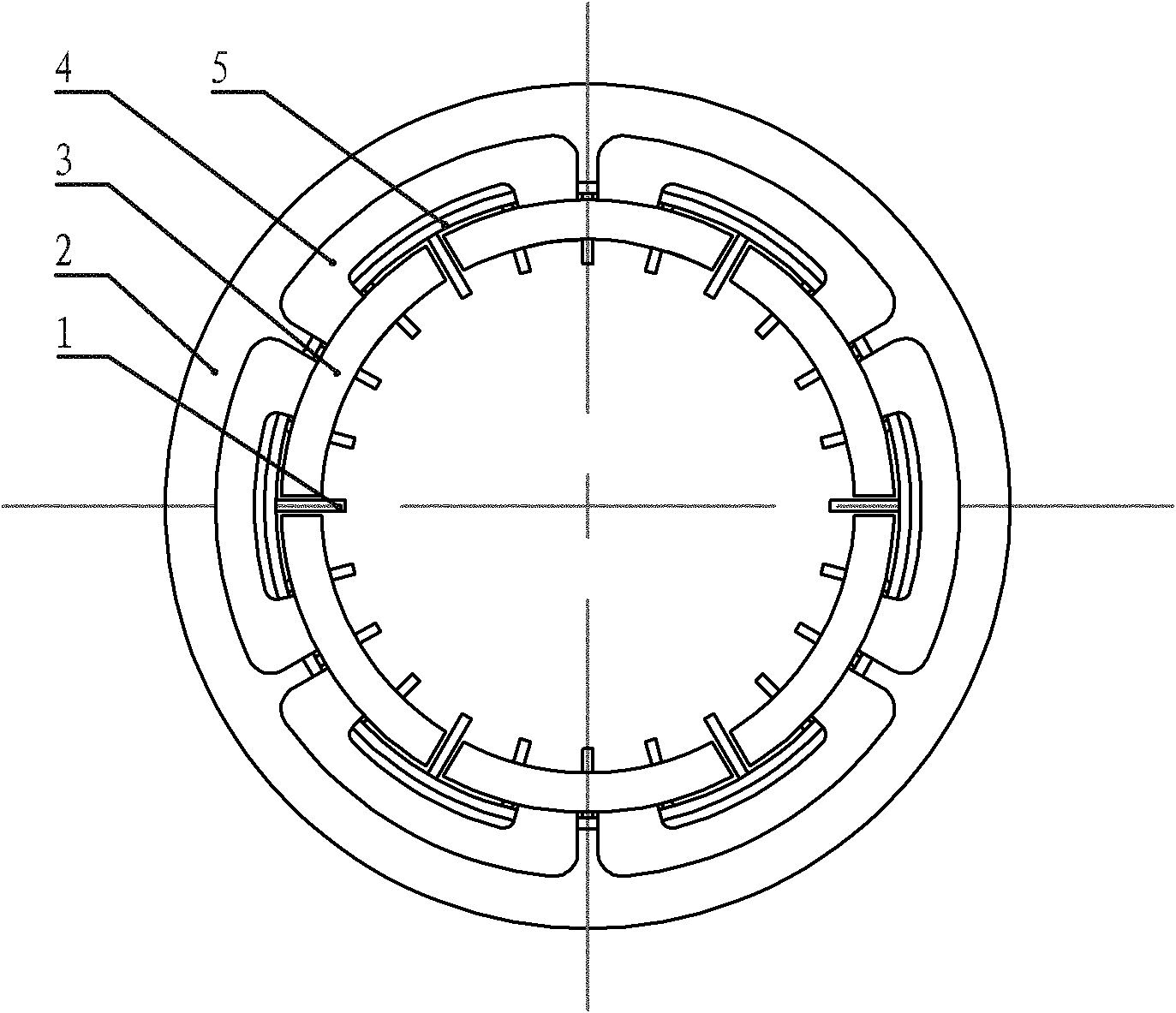

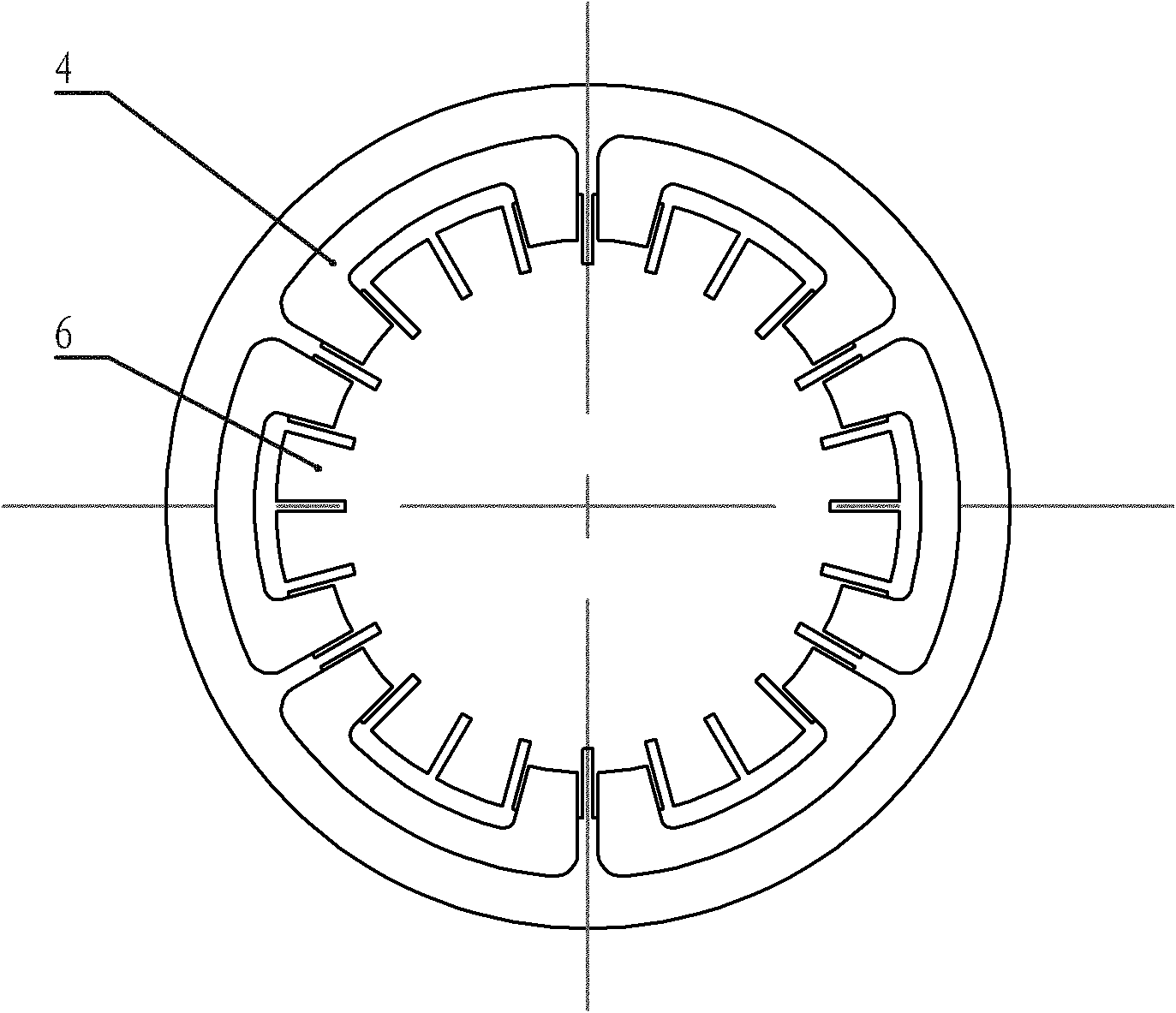

[0010] Embodiment 1: A kind of high-efficiency three-phase slotless permanent magnet motor described in this embodiment is a cylindrical rotating electrical machine, which is composed of an armature, a rotor and an air gap; the armature is composed of an armature core 2, a winding and Composed of a coil frame, the armature core 2 is circular, the coil frame is composed of a thin-walled tube 5 and 6p thin partitions 1, p is the number of pole pairs of the permanent magnet of the motor rotor, p≥2, the thin-walled tube 5 is coaxial with the armature core 2 and is fixed on the side of the armature core 2 close to the rotor. The thin partitions 1 are elongated, and each thin partition 1 is radial with the axis of the armature core 2 as the axis of symmetry. Evenly distributed and fixed on the side wall of the thin-walled cylinder 5 near the rotor side, and the planes where all the thin-walled partitions 1 are located intersect with the axis of the armature core 2, and the two adjace...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment is a further limitation of the high-efficiency three-phase slotless permanent magnet motor described in Embodiment 1. In this embodiment, a plurality of skeletons are evenly distributed in the axial direction on the side of the stator core adjacent to the rotor. The positioning groove, the positioning rib is embedded in the positioning groove, so that the coil skeleton is fixed between the positioning rib and the skeleton positioning groove.

[0014] In this embodiment, a device for fixing the coil frame is added, so that the coil frame can be stably fixed on the stator core.

specific Embodiment approach 3

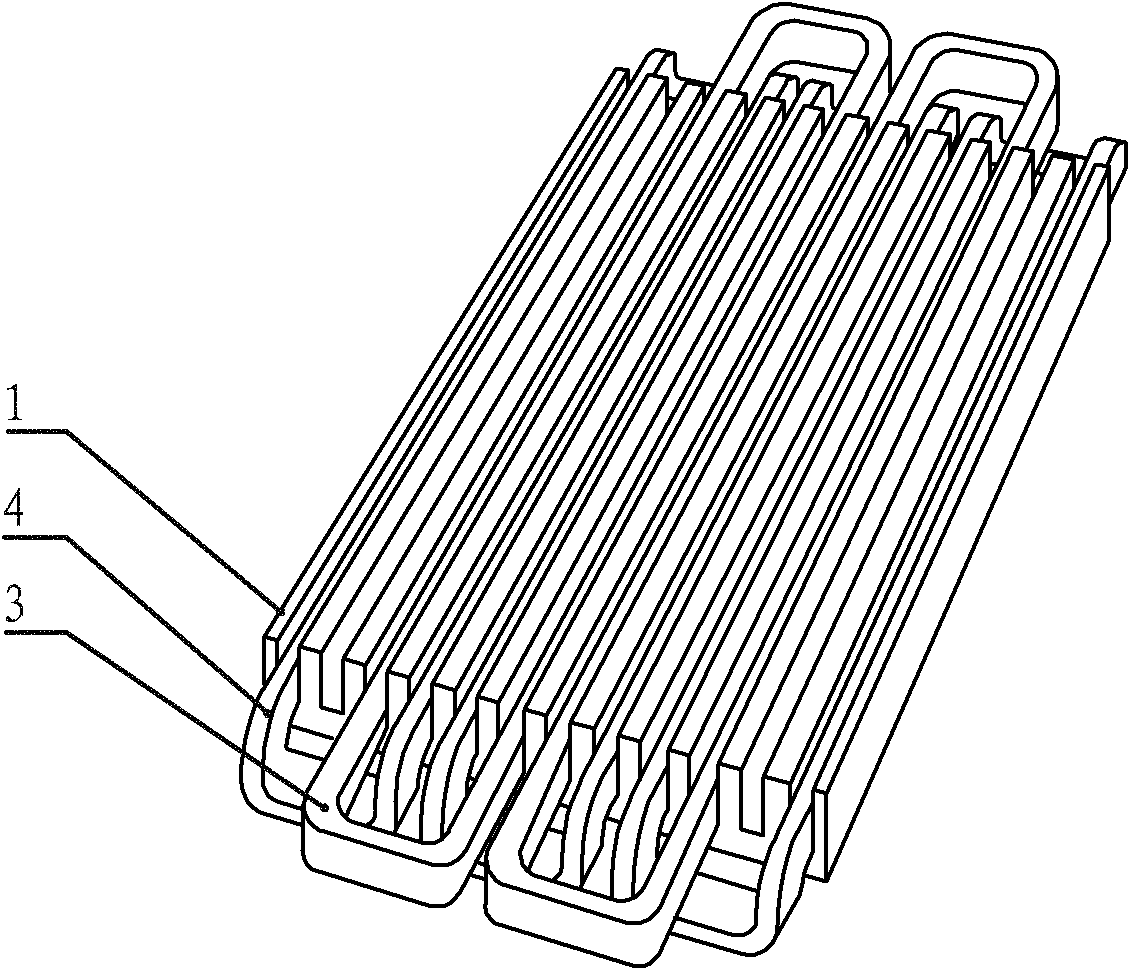

[0015] Specific Embodiment Three: A high-efficiency three-phase slotless permanent magnet linear motor described in this embodiment is a flat motor, which consists of a primary, a secondary, and an air gap; the secondary of the motor is a bilateral structure, and each side of the secondary It is composed of a yoke plate and a permanent magnet. The primary is located between two secondary plates. The primary includes a coil, a coil frame and a primary output plate; the coil frame is composed of a thin plate and several thin partitions. The thin plate is parallel to the secondary, thin The baffles are strip-shaped, and each thin baffle is perpendicular to the thin plate at equal intervals along the moving direction of the mover and is fixed on the thin plate. A line groove is formed between two adjacent thin baffles. The slot pitch is equal to the secondary pole pitch, and all coils have the same shape, consisting of two straight sides and two ends, both of which are bent towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com