Current setting method for open-circuit fault tolerance control of five-phase permanent magnet synchronous motor

A permanent magnet synchronous motor, winding open circuit technology, applied in the direction of torque ripple control, etc., can solve the problem of weak torque output capacity of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

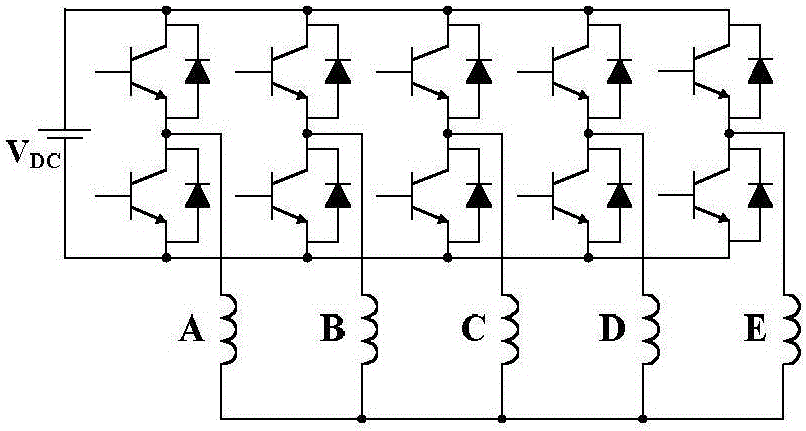

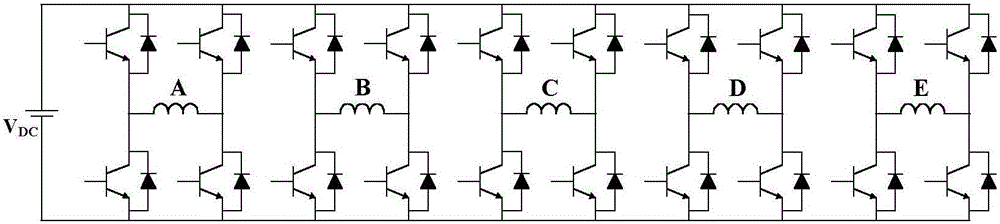

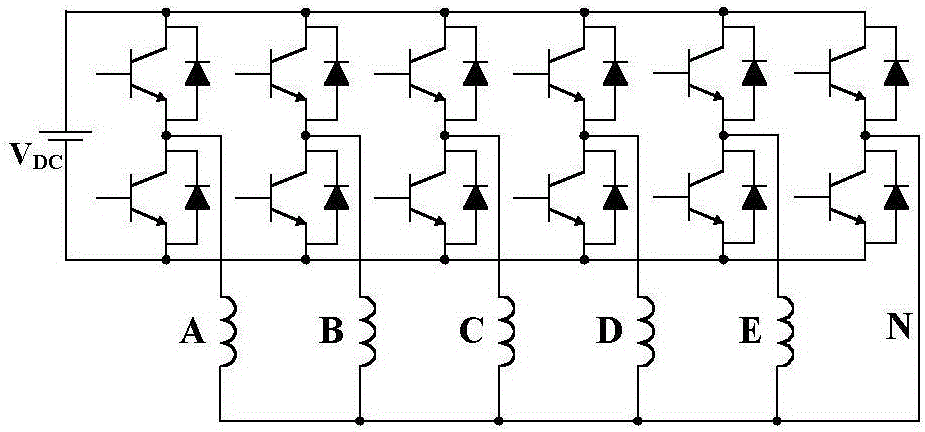

[0132] Specific implementation mode one: the following combination Figure 2 to Figure 5 This embodiment is described. The current setting method used in the five-phase permanent magnet synchronous motor winding open-circuit fault fault-tolerant control described in this embodiment is the case of one-phase open circuit.

[0133] A five-phase permanent magnet synchronous motor can use a five-phase full-bridge inverter (such as figure 2 shown) or five-phase six-leg inverter (such as image 3 shown) for power supply, where image 3 The topology shown is disclosed in the Chinese patent "Neighboring Five-Vector SVPWM Method Based on Five-Phase Six-Wire Topology" with publication number CN103051273A. The schematic diagram of the winding space of a five-phase permanent magnet synchronous motor is shown in Figure 4 shown.

[0134] The number of turns in series for each phase of the five-phase permanent magnet synchronous motor A, B, C, D, and E phase windings is N, and the axes ...

specific Embodiment approach 2

[0174] Specific embodiment two: below in conjunction with 2 to Figure 4 , Image 6 with Figure 7 This embodiment is described. The current setting method used in the five-phase permanent magnet synchronous motor winding open-circuit fault fault-tolerant control described in this embodiment is the case of two-phase open-circuit.

[0175] A five-phase permanent magnet synchronous motor can use a five-phase full-bridge inverter (such as figure 2 shown) or five-phase six-leg inverter (such as image 3 shown) for power supply, where image 3 The topology shown is disclosed in the Chinese patent "Neighboring Five-Vector SVPWM Method Based on Five-Phase Six-Wire Topology" with publication number CN103051273A. The schematic diagram of the winding space of a five-phase permanent magnet synchronous motor is shown in Figure 4 shown.

[0176] The number of turns in series for each phase of the five-phase permanent magnet synchronous motor A, B, C, D, and E phase windings is N, a...

specific Embodiment approach 3

[0221] Specific embodiment three: below in conjunction with 2 to Figure 4 , Figure 8 with Figure 9 This embodiment is described. The current setting method used in the five-phase permanent magnet synchronous motor winding open-circuit fault fault-tolerant control described in this embodiment is for the case of three-phase open circuit.

[0222] A five-phase permanent magnet synchronous motor can use a five-phase full-bridge inverter (such as figure 2 shown) or five-phase six-leg inverter (such as image 3 shown) for power supply, where image 3 The topology shown is disclosed in the Chinese patent "Neighboring Five-Vector SVPWM Method Based on Five-Phase Six-Wire Topology" with publication number CN103051273A. The schematic diagram of the winding space of a five-phase permanent magnet synchronous motor is shown in Figure 4 shown.

[0223] The number of turns in series for each phase of the five-phase permanent magnet synchronous motor A, B, C, D, and E phase winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com