Synchronous electric main shaft acceleration strong magnetic control method for variable-load superhigh-speed grinding

A technology of ultra-high-speed grinding and control method, which is applied in the direction of electronic commutation motor control, motor generator control, control system, etc., which can solve the problems of lack of tracking ability, difficulty in constant power expansion, and difficulty in adapting to variable loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

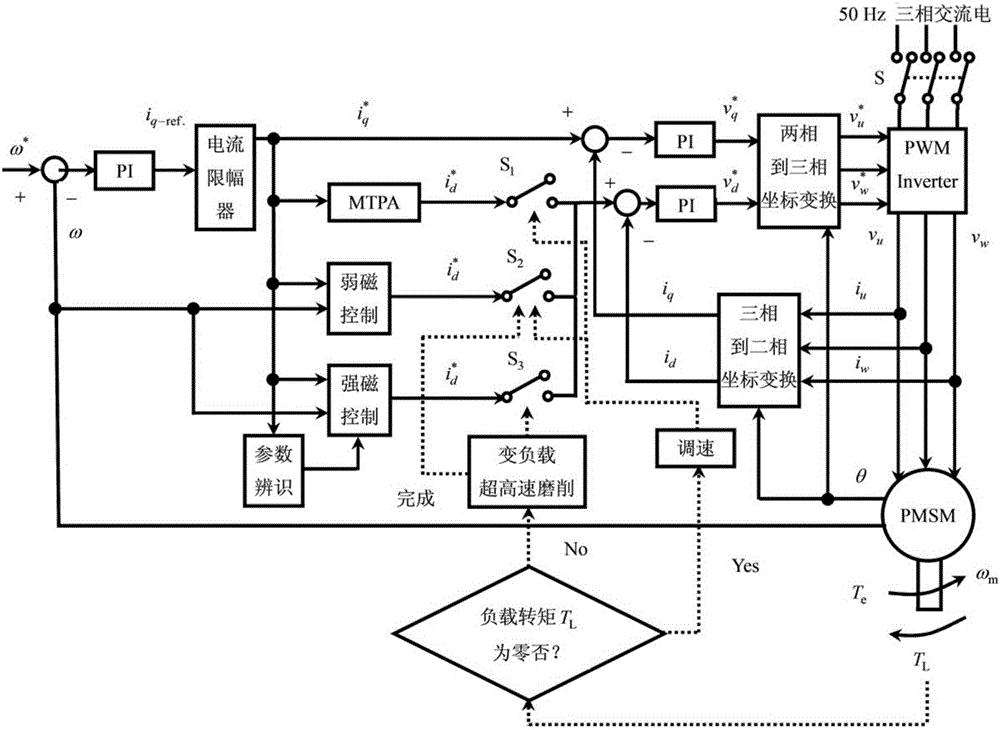

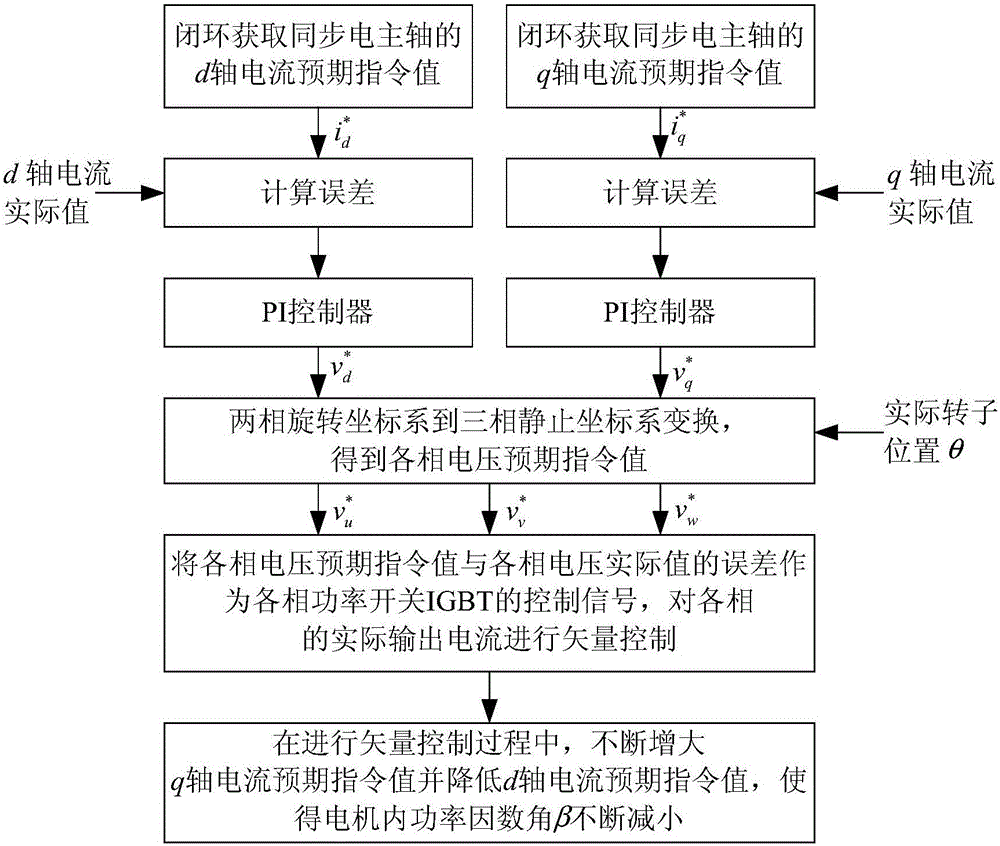

[0043] In the following, the synchronous motorized spindle for variable load ultrahigh speed grinding of the present invention will be added on the basis of the traditional constant magnetic (MTPA) control method + "weakening field" control method for the synchronous motorized spindle for variable load ultrahigh speed grinding. Taking the jerk control ("strong magnet" control method) as an example, the synchronous motor spindle jerk control method for variable load ultra-high-speed grinding of the present invention will be further described in detail.

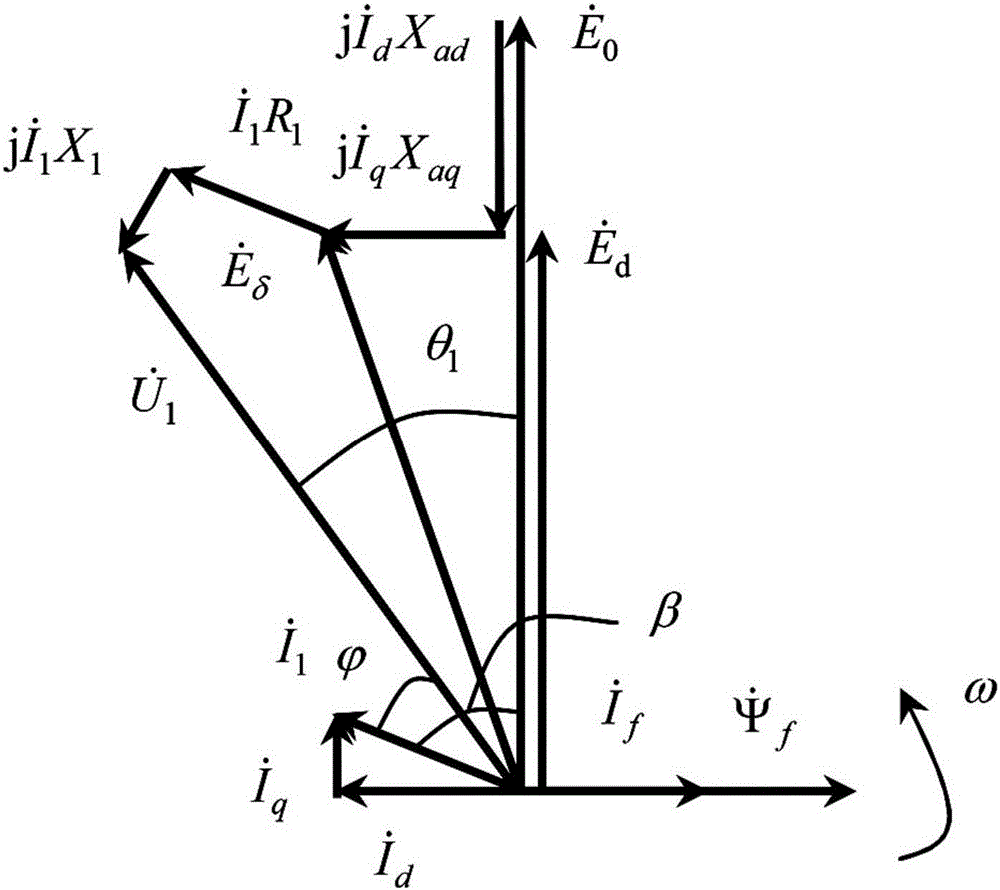

[0044] The "strong field" control of permanent magnet synchronous motor spindle jerk is actually the reverse control process of field weakening control. To clarify the "strong magnetic" control principle, we must first clarify the "weak magnetic" control principle, and its principles can be found in figure 1 ,in, is the effective value of the no-load back EMF of each phase generated by the permanent magnetic air-gap fundament...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com