Antibacterial composite functional fiber and preparation method thereof

A functional fiber, composite technology, applied in the field of polyester fiber production, can solve the problems of tourmaline powder agglomeration, poor mixing effect, difficult spinning and forming, etc., to increase dispersion stability, reduce agglomeration effect, enhance antibacterial and far-infrared effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

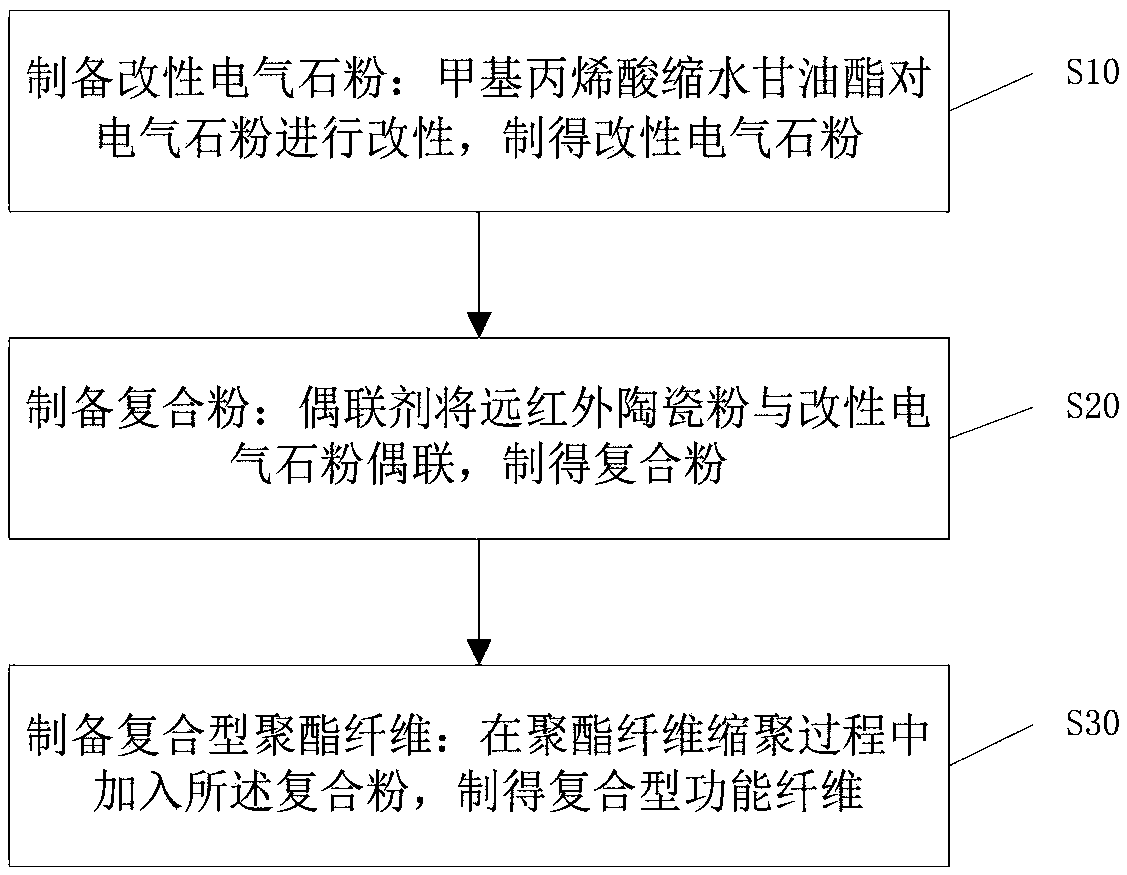

[0031] Such as figure 1 Shown, the present invention proposes a kind of preparation method of antibacterial composite functional fiber, comprises the following steps:

[0032] S10, preparing modified tourmaline powder: taking 18-25 parts by mass of tourmaline powder, 45-60 parts by mass of glycidyl methacrylate, and 5-8 parts by mass of silane coupling agent, mixing, grinding and pulverizing, and making tourmaline material I; Take 0.8-2.0 parts by mass of peroxide initiator, add 100 parts by mass of the tourmaline material I and mix evenly to obtain tourmaline material II; take 200 parts by mass of water and 100 parts by mass of polyvinyl alcohol aqueous solution with a concentration of 100g / L , in a nitrogen environment, add the tourmaline material II to carry out the reaction, collect the solid precipitate after the reaction, dry, grind and pulverize to prepare the modified tourmaline powder.

[0033] The specific steps for preparing modified tourmaline powder from tourmali...

Embodiment 1

[0043] S11 Preparation of modified tourmaline powder

[0044] Weigh 20 parts by mass of tourmaline powder, 50 parts by mass of glycidyl methacrylate, and 8 parts by mass of silane coupling agent, add them into a grinding tank, stir evenly, and grind for 2 hours with a ball mill to make tourmaline material I. Weigh 0.8 parts by mass of dibenzoyl peroxide as an initiator and 100 parts by mass of the tourmaline material I, stir and mix to obtain tourmaline material II. Weigh 200 parts by mass of water and 100 parts by mass of polyvinyl alcohol aqueous solution with a concentration of 100g / L into a three-necked flask, stir well and pass in nitrogen protection, heat in a constant temperature water bath to 40°C, then add the tourmaline material II, 500-550rpm Stir and react for 30 minutes; raise the temperature to 70°C, reduce the stirring speed to 200-300rpm, and react for 2h; continue to raise the temperature to 80°C, stir and react at 200-300rpm for 3h, stop stirring, stand still...

Embodiment 2

[0050] S21 Preparation of modified tourmaline powder

[0051] Weigh 25 parts by mass of tourmaline powder, 60 parts by mass of glycidyl methacrylate, and 6 parts by mass of silane coupling agent, add them into a grinding tank, stir evenly, and grind for 2 hours with a ball mill to prepare tourmaline material I. Weigh 1.6 parts by mass of dibenzoyl peroxide as an initiator and 100 parts by mass of the tourmaline material I, stir and mix to obtain tourmaline material II. Weigh 200 parts by mass of water and 100 parts by mass of polyvinyl alcohol aqueous solution with a concentration of 100g / L into a three-necked flask, stir well and pass in nitrogen protection, heat in a constant temperature water bath to 40°C, then add the tourmaline material II, 500-550rpm Stir and react for 30 minutes; raise the temperature to 70°C, reduce the stirring speed to 200-300rpm, and react for 2h; continue to raise the temperature to 80°C, stir and react at 200-300rpm for 3h, stop stirring, stand st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com