Nylon composition, preparation method and applications thereof

A composition, nylon technology, applied in the field of polymer modified materials, can solve the problems of obvious impact on mechanical properties and low mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

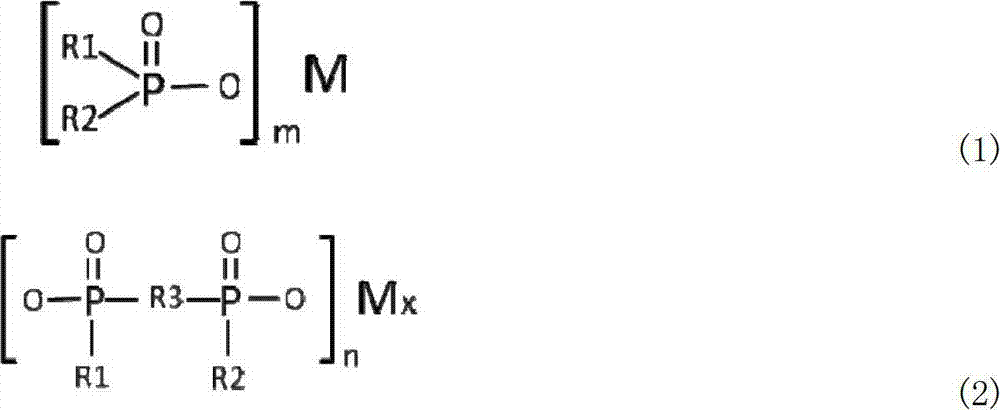

Method used

Image

Examples

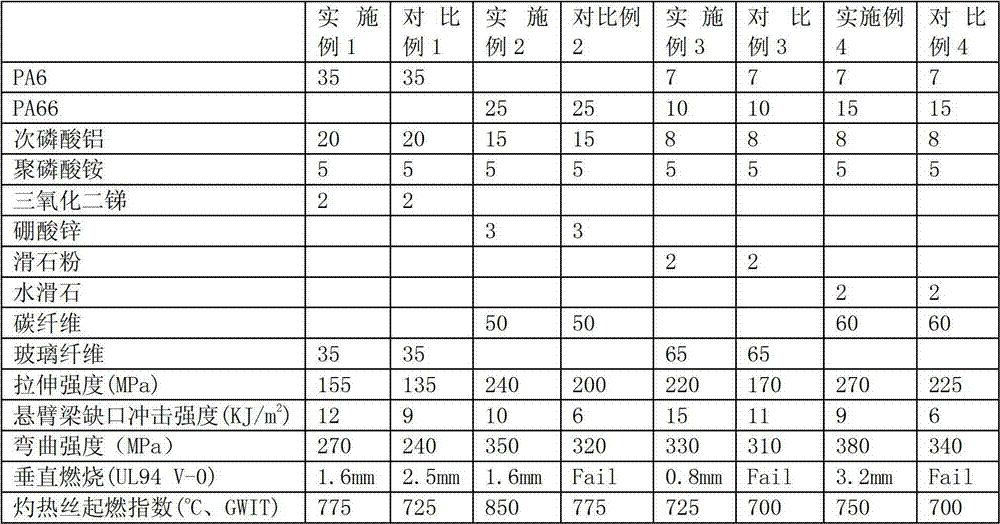

Embodiment 1

[0053] Add 35 parts by weight of nylon 6 (viscosity 2.4), 0.2 parts by weight of antioxidant 1010, 0.3 parts by weight of copper salt composite antioxidant, 0.5 parts by weight of pentaerythritol stearate, and 2 parts by weight of SMA into a high mixer, 20 parts by weight Parts of aluminum hypophosphite, 5 parts by weight of ammonium polyphosphate, and 2 parts by weight of antimony trioxide are mixed uniformly at room temperature, and then passed into the extruder through the main feed port of the twin-screw extruder. The process conditions of the extruder are : The first section of the eight-section twin-screw extruder is the feeding section, the second section is the mixing compression section, the third and fourth sections are the melting section, and the latter section is the homogenization section. The temperature of the feeding section of the twin-screw extruder is 230-250°C, the temperature of the mixing compression section is 250-270°C, the temperature of the melting se...

Embodiment 2

[0059] 25 parts by weight of nylon 66 (viscosity 2.4), 0.2 parts by weight of antioxidant 1098, 0.3 parts by weight of copper salt composite antioxidant, 1 part by weight of oxidized polyethylene wax, 0.5 parts by weight of EMA, 15 parts by weight of aluminum hypophosphite, 5 parts by weight Add ammonium polyphosphate and 3 parts by weight zinc borate into the high-mixer and mix evenly at room temperature, and then pass into the extruder through the main feed port of the twin-screw extruder. The process conditions of the extruder are: eight stages The first section of the twin-screw extruder is the feeding section, the second section is the mixing compression section, the third and fourth sections are the melting section, and the latter section is the homogenization section. The temperature of the feeding section of the twin-screw extruder is 230-250°C, the temperature of the mixing compression section is 250-270°C, the temperature of the melting section is 260-280°C, the tempe...

Embodiment 3

[0064] 10 parts by weight of nylon 66 (viscosity 2.7), 7 parts by weight of nylon 6 (viscosity 2.4), 0.2 parts by weight of antioxidant 1098, 0.3 parts by weight of copper salt composite antioxidant, 2 parts by weight of montan wax, 0.5 parts by weight of SMA, Add 8 parts by weight of aluminum hypophosphite, 5 parts by weight of ammonium polyphosphate and 2 parts by weight of talcum powder into the high mixer, mix evenly at room temperature, and then pass into the extruder through the main feed port of the twin-screw extruder Among them, the process conditions of the extruder are: the first section of the ten-section twin-screw extruder is the feeding section, the second section is the mixing compression section, the third and fourth sections are the melting section, and the latter section is the homogenization section. The temperature of the feeding section of the twin-screw extruder is 230-250°C, the temperature of the mixing compression section is 250-270°C, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com