Preparation method of light-cured 3D printing Thiessen polygon bionic structure tricalcium phosphate/silicon dioxide composite biological ceramic

A technology of composite bioceramics and Thiessen polygons, applied in the field of additive manufacturing, can solve the problems of low fracture toughness, high brittleness, and poor compressive resistance of tricalcium phosphate ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

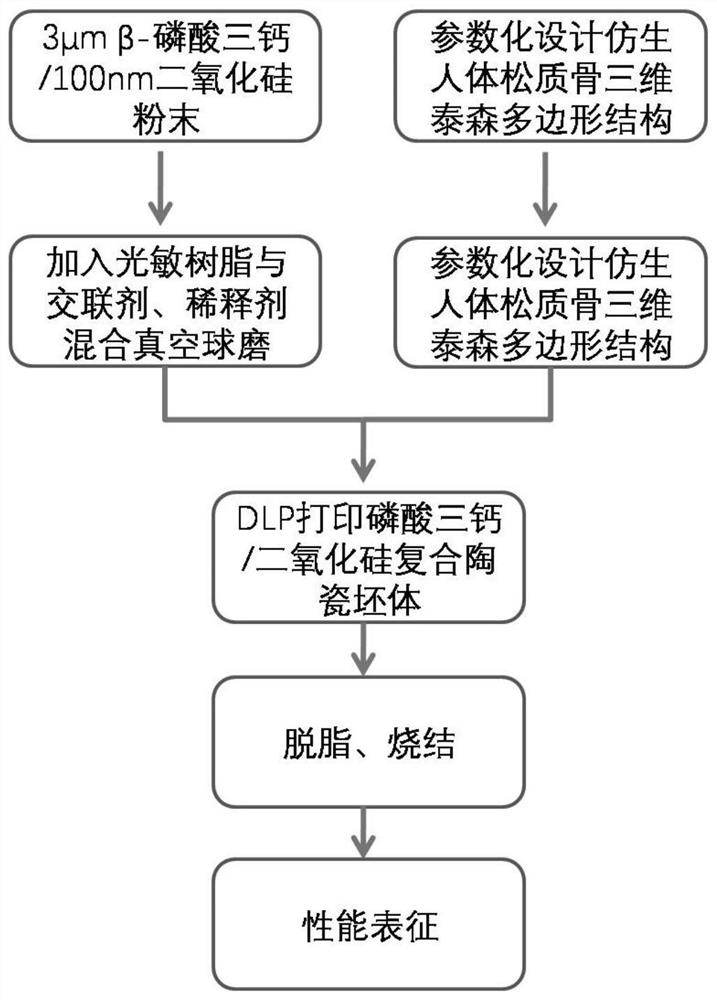

Method used

Image

Examples

Embodiment 1

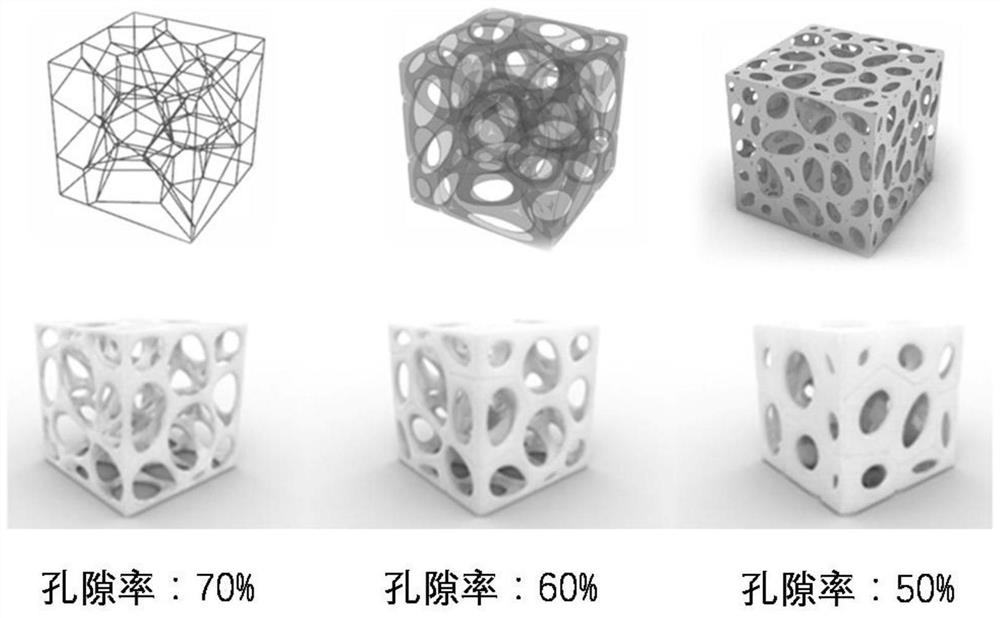

[0041] 1. Using Rhino 3D modeling software combined with Grasshopper parametric design platform, taking the bone trabecular structure between human cancellous bones as the bionic target, based on the 3D Thiessen polygon structure, and controlling the design porosity by changing the number of random points and the point spacing Bionic structural scaffolds ranging in size from 50%-80%.

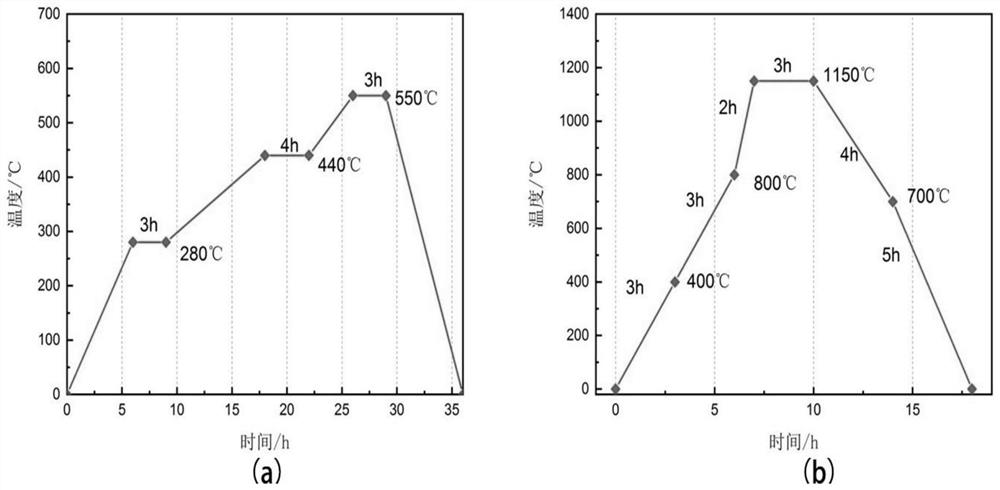

[0042] 2. Configure the light-cured ceramic slurry required for printing under dark light conditions, and separate the β-TCP ceramic powder with an average particle size of 30 μm-50 μm, the silicon dioxide powder with a particle size of less than 0 nm, and the photosensitive resin with a wavelength of 405 nm. After weighing, put it into a beaker at a ratio of 0.3:0.0003:1 for magnetic stirring at room temperature and mix evenly at a speed of n=60r / min to obtain the initial mixed slurry A. Add the cross-linking agent 3,3-dimethacrylic acid to the mixed slurry A, and its mass ratio to the mixed sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com