Preparation method of nano silicon dioxide reinforced nylon 6 composite

A nano-silica and composite material technology is applied in the field of preparation of nano-silica reinforced nylon 6 composite materials, which can solve problems such as nanoparticle agglomeration, and achieve the effects of improving interface bonding force, enhancing toughness and reducing agglomeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

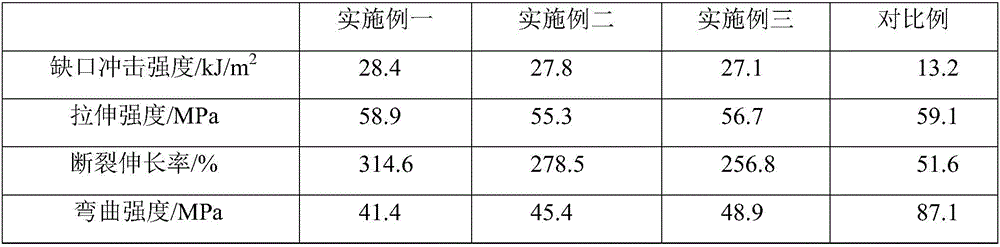

Embodiment 1

[0024] Step 1: Stir 186mL of ethyl silicate, 59mL of water, and 59mL of absolute ethanol in a 50°C water bath, add 0.002mol of catalyst hydrochloric acid, and continue stirring for 1 hour to prepare a clear blended solution;

[0025] Step 2: Add 2500g of caprolactam, stir evenly, and gel for 5 hours at a system temperature of 75°C;

[0026] The third step: at a system temperature of 235°C and a system pressure of 0.7 MPa, the ring-opening hydrolysis and prepolymerization of caprolactam are carried out, and at the same time, the gel dehydration of the silicate compound is carried out, and the polymerization time is 2 hours;

[0027] Step 4: Carry out reduced-pressure compression polymerization of caprolactam at a system temperature of 240°C and a system vacuum of 0.1 MPa, and the polymerization time is 4 hours;

[0028] Step 5: Cool and break the prepolymer obtained by polymerization, add 0.024mol of chain extender glycidyl methacrylate, and 0.005mol of molecular weight regulat...

Embodiment 2

[0030]Step 1: Stir 600mL of ethyl silicate, 193mL of water, and 290mL of acetone in a 60°C water bath, add 0.003mol of catalyst hydrochloric acid, and continue stirring for 1.5h to prepare a clear blend solution;

[0031] Step 2: Add 4000g of caprolactam, stir evenly, and gel for 4 hours at a system temperature of 75°C;

[0032] The third step: at a system temperature of 250°C and a system pressure of 0.8 MPa, the ring-opening hydrolysis and pre-polymerization of caprolactam are carried out, and at the same time, the gel dehydration of silicate compounds is carried out, and the polymerization time is 2.5 hours;

[0033] Step 4: Carry out reduced-pressure compression polymerization of caprolactam at a system temperature of 240°C and a system vacuum of 0.1 MPa, and the polymerization time is 4.5 hours;

[0034] Step 5: Cool and break the prepolymer obtained by polymerization, add 0.024mol of chain extender 1,6-hexamethylene diisocyanate, 0.005mol of molecular weight regulator et...

Embodiment 3

[0036] Step 1: Stir 500mL of ethyl silicate, 161mL of water, and 120mL of n-butanol in a 55°C water bath, add 0.006mol of a catalyst sodium chloride aqueous solution, and continue stirring for 1.5h to prepare a clarified blended solution;

[0037] Step 2: Add 7000g of caprolactam, stir evenly, and gel for 4 hours at a system temperature of 65°C;

[0038] The third step: at a system temperature of 215°C and a system pressure of 0.6 MPa, the ring-opening hydrolysis and pre-polymerization of caprolactam are carried out, and at the same time, the gel dehydration of the silicate compound is carried out, and the polymerization time is 2 hours;

[0039] Step 4: Carry out reduced-pressure compression polymerization of caprolactam at a system temperature of 255°C and a system vacuum of 0.08 MPa, and the polymerization time is 3 hours;

[0040] Step 5: Cool and break the prepolymer obtained by polymerization, add 0.048mol of chain extender glycidyl methacrylate and 0.015mol of molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com