Flexible temperature sensor and preparation method thereof

A temperature sensor, flexible technology, applied in thermometers, thermometer applications, instruments, etc., can solve the problems of weakening the agglomeration effect, increasing the distance between graphene sheets by electrostatic repulsion, reducing the van der Waals force between graphene particles, etc., so as to weaken the agglomeration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

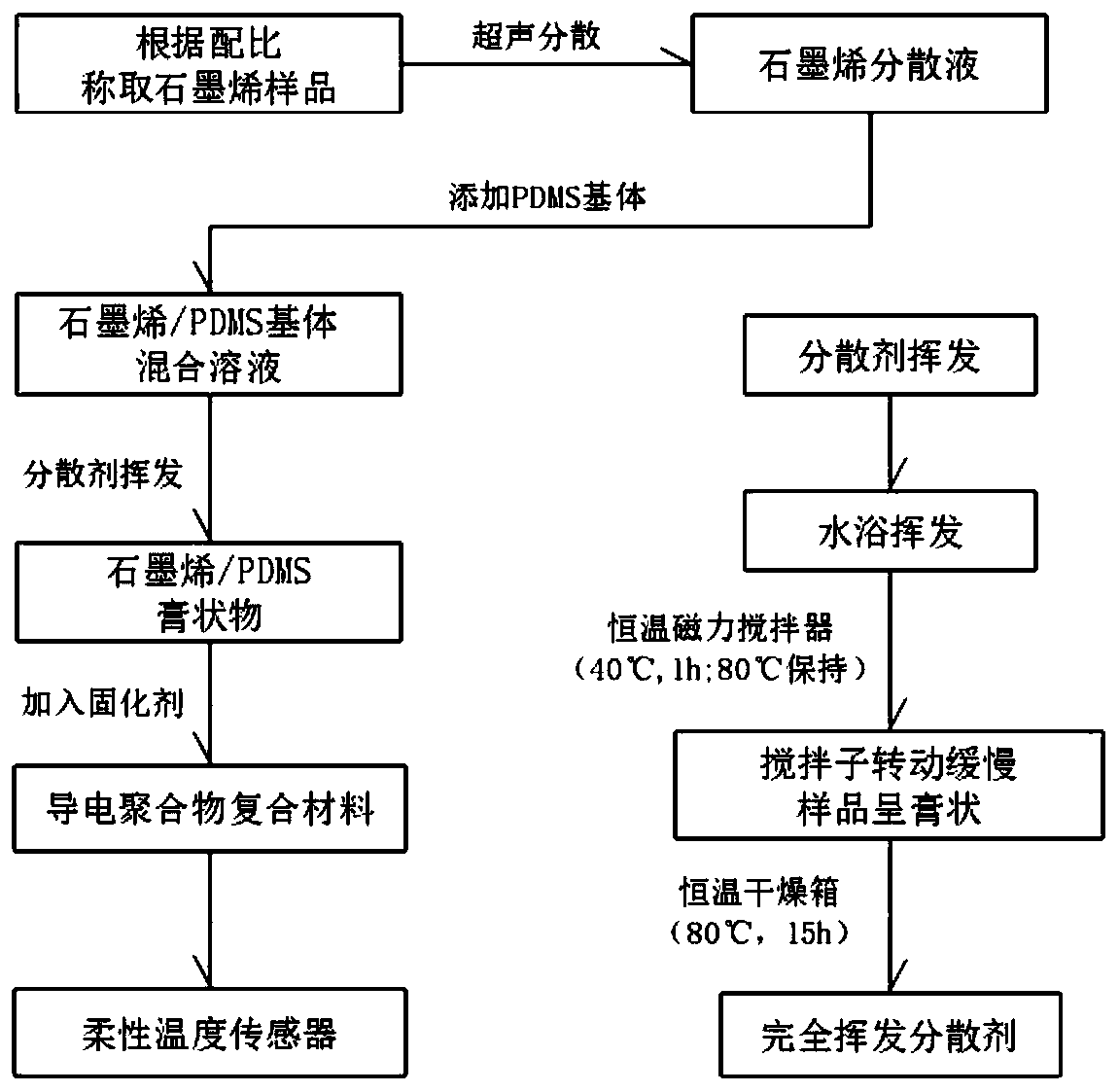

[0050] Based on the above experiments, the present invention discloses a method for preparing a flexible temperature sensor, comprising the following steps:

[0051] The graphene sample is subjected to ultrasonic dispersion treatment to obtain a prepared graphene dispersion;

[0052] Adding a PDMS matrix to the prepared graphene dispersion to obtain a graphene-PDMS composite dispersion;

[0053] removing the dispersant in the graphene-PDMS composite dispersion solution to obtain the graphene-PDMS composite solution;

[0054] Adding a PDMS curing agent to the graphene-PDMS composite solution to obtain a graphene-PDMS curing solution;

[0055] The graphene-PDMS solidified solution is subjected to degassing treatment, and the graphene-PDMS solidified solution after degassing treatment is injected into the mould;

[0056] The graphene-PDMS curing solution injected into the mold is heated and cured to obtain the prepared flexible temperature sensor.

[0057] In the preparation m...

Embodiment 1

[0059] Such as image 3 Shown, in the present embodiment, adopt isopropanol as dispersant, and adopt low-power ultrasonic dispersion, specifically comprise the following steps:

[0060] (1) according to proportioning calculation required graphene: the mass ratio (curing agent: matrix=1:10) content of PDMS matrix;

[0061] (2) Weigh a quantitative graphene sample, pour it into isopropanol solvent according to the mass ratio of 1:60, and mix to obtain a graphene dispersion: isopropanol is slightly toxic and volatile, and the experimental operation is completed in a fume hood. Since graphene monomer is easy to entangle, adding isopropanol can make graphene disperse evenly, which is conducive to the formation of cross-linked network;

[0062] (3) Low-power ultrasonic dispersion: Ultrasound is used to disperse graphene more uniformly in isopropanol solution. Put the graphene dispersion into the Figure 4 In the ultrasonic cleaning machine shown (power 180W), since heat will be g...

Embodiment 2

[0072] Embodiment two is the extended embodiment of embodiment one, and its difference with embodiment one is, in the present embodiment, what use is that nitrogen methyl pyrrolidone (NMP) solvent replaces isopropanol solution as the dispersion of graphene Because the boiling point of isopropanol is 82.45 DEG C, it can be volatilized under the situation of water bath 80 DEG C, and the boiling point of nitrogen methyl pyrrolidone (NMP) is 203 DEG C, cannot volatilize under water bath condition, therefore, in the dispersant volatilization step , using as Figure 5 The volatilization process of the dispersant shown is volatilization, specifically:

[0073] During the volatilization process of the dispersant, the sample is placed on a constant temperature heating platform, and an asbestos net is placed on it (to ensure that the sample is heated evenly), and the temperature of the heating platform is adjusted to 230°C (there is a temperature loss during the heating process), and "a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com