Doped-type carbon/manganese sulfide composite material preparation method

A composite material, manganese sulfide technology, applied in nanotechnology, fuel cells, electrochemical generators for materials and surface science, etc., can solve the problem of difficult to achieve large-scale promotion, inability to recover or recycle, and complex synthesis process. and other problems, to achieve the effects of high utilization rate of reaction raw materials, excellent oxygen catalytic performance, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

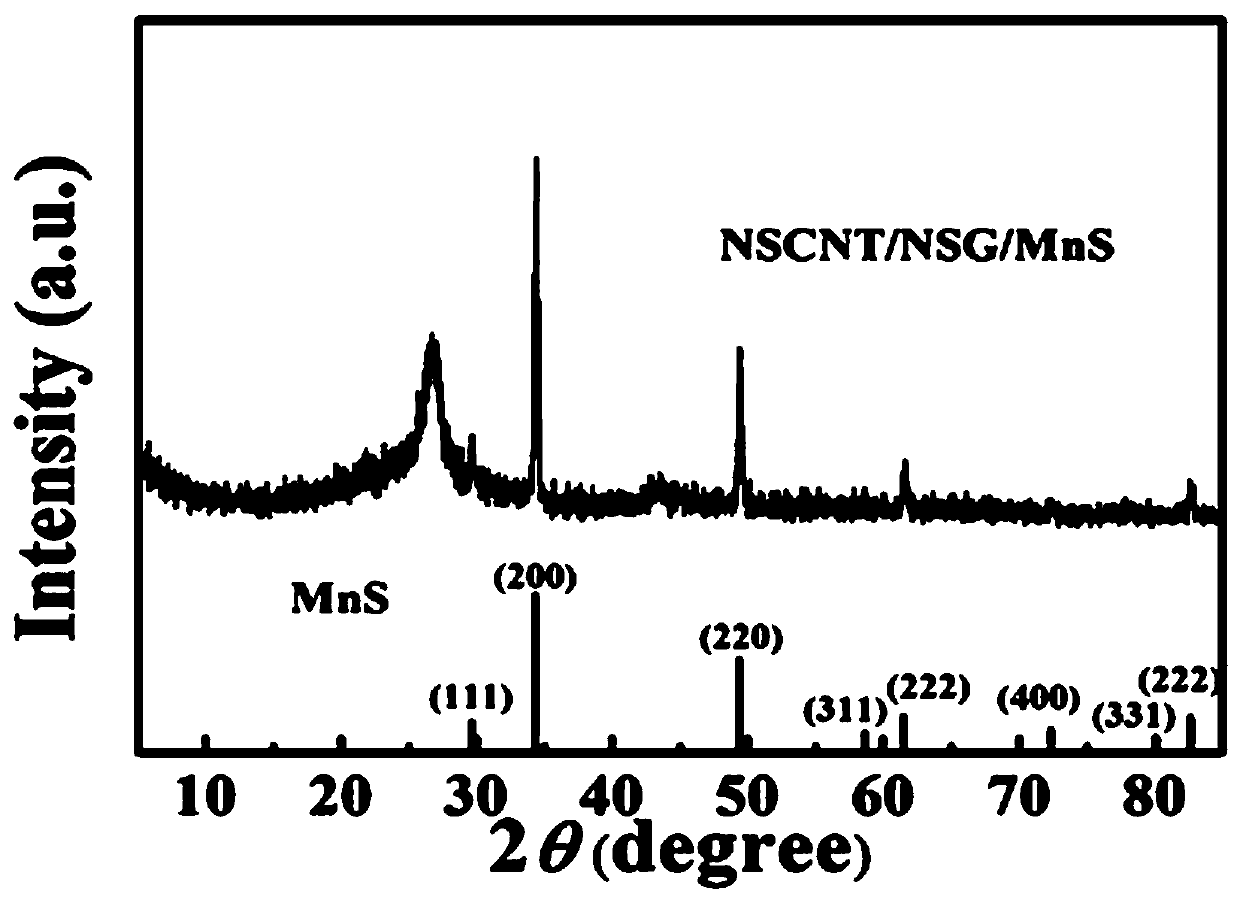

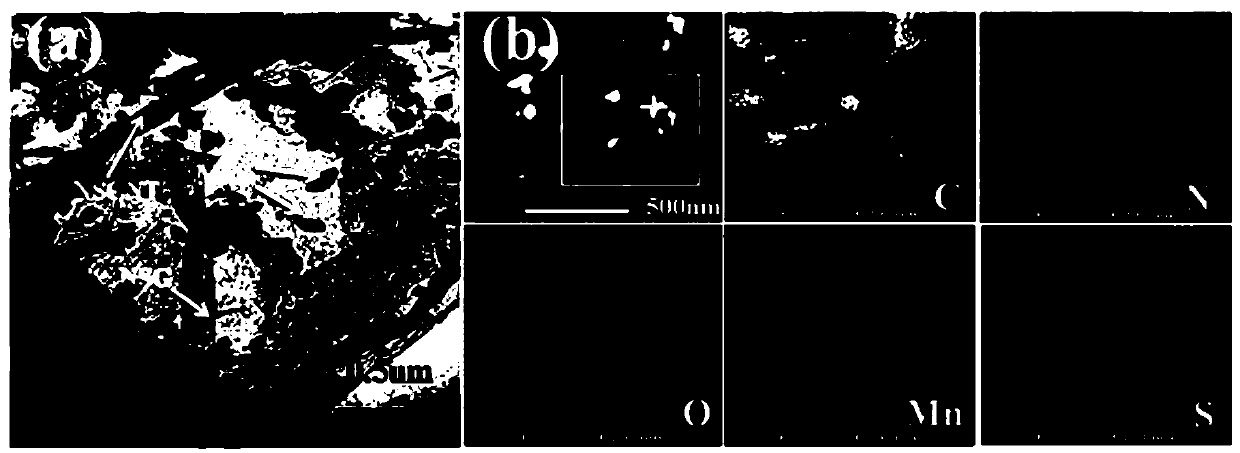

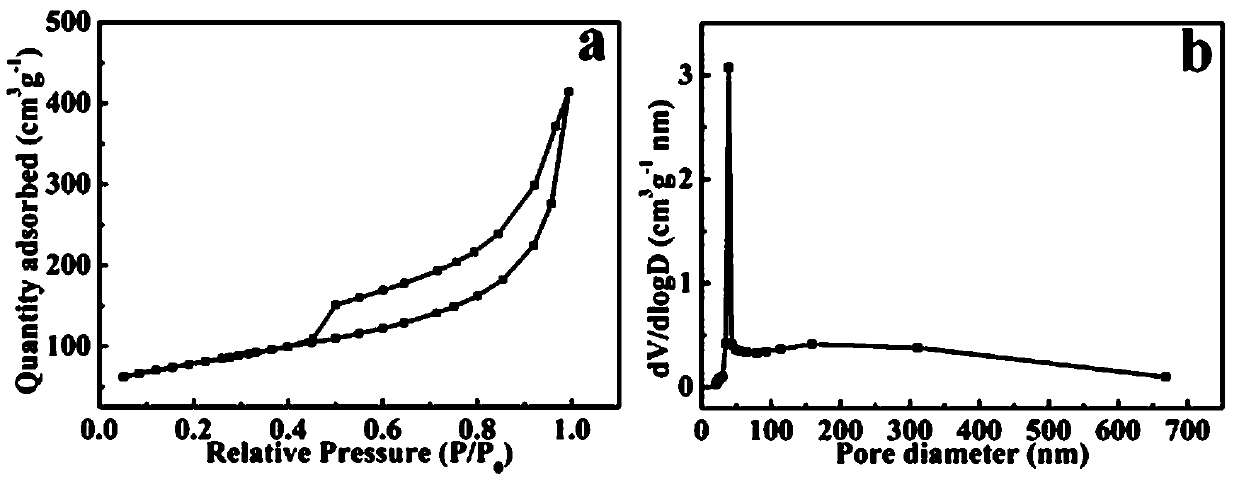

[0038] Take 0.5 g of sodium nitrate and 45 mL of 70% concentrated sulfuric acid in a 250 mL round-bottomed flask, slowly add 0.5 g of multi-walled carbon nanotubes and 0.5 g of graphite powder in turn under ice bath conditions (around 0 °C), and stir After 20 min, a homogeneous mixture was obtained; add 5 g of potassium permanganate to the above mixture, stir for 10 min, then raise the temperature to 40 °C, and react for 24 h, transfer the reaction product to a 1 L beaker, add deionized Dilute to 500 mL with water, then add 5 mL of hydrogen peroxide (30%), then add 50 mL of 30% concentrated hydrochloric acid, and stir thoroughly for 2 h. After the reaction solution was left to stand for 1 day, the solution was clearly separated, and the supernatant was removed to obtain the lower precipitate. The obtained precipitate was dried, mixed with urea at a mass ratio of 1:6, and calcined at 800 °C for 2 h in a nitrogen atmosphere to obtain nitrogen-sulfur double-doped carbon nanotube / ...

Embodiment 2

[0046] Take 0.5 g of potassium nitrate and 45 mL of 70% concentrated sulfuric acid in a 250 mL round bottom flask, slowly add 1 g of multi-walled carbon nanotubes under ice bath conditions (around 0 °C), and stir for 20 min to obtain a uniform Mixed solution; add 5 g of potassium permanganate to the above mixed solution, stir for 15 min, then heat up to 40 °C, react for 20 h, transfer the reaction product to a 1 L beaker, add deionized water to dilute to 500 mL, Then add 5 mL of hydrogen peroxide (30%), followed by adding 50 mL of 30% concentrated hydrochloric acid, and stir thoroughly for 2 h. After the reaction solution was left to stand for 1 day, the solution was clearly separated, and the supernatant was removed to obtain the lower precipitate. The obtained precipitate was dried, mixed with urea at a mass ratio of 1:10, and calcined at 800 °C for 2 h in a nitrogen atmosphere to finally obtain a nitrogen-sulfur double-doped carbon nanotube / manganese sulfide composite (NSCN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com