Ultraviolet resistant polyester fiber master batch and preparation method thereof, and production method of polyester fiber containing ultraviolet resistant polyester fiber master batch

A polyester fiber masterbatch and anti-ultraviolet technology, which is applied in the direction of fiber chemical characteristics, single-component polyester rayon, rayon manufacturing, etc., can solve the problems of anti-ultraviolet material particle agglomeration and poor mixing effect, and achieve cost reduction low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

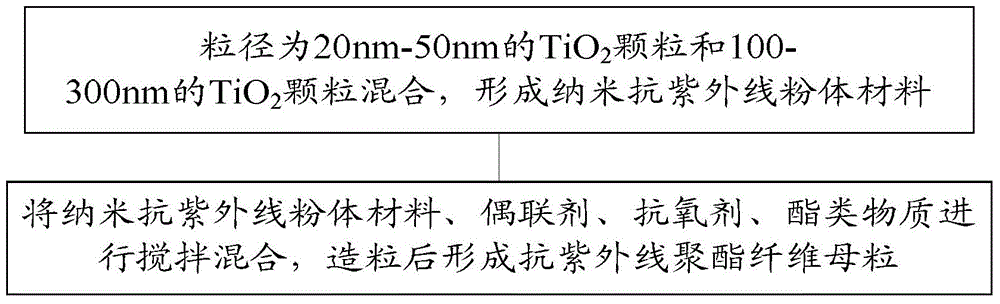

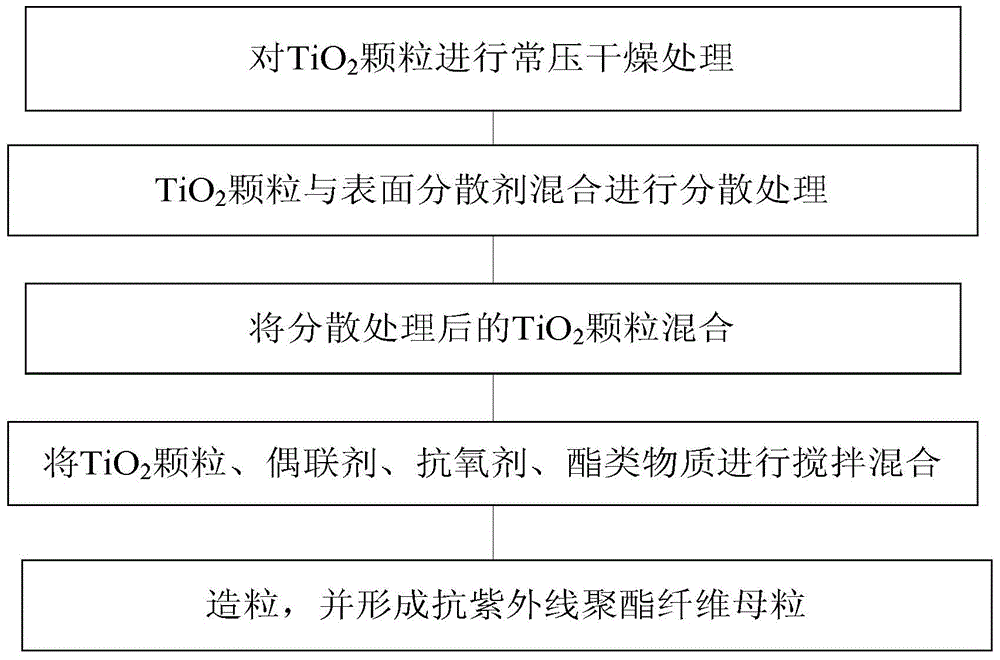

[0023] Such as figure 1 As shown, the preparation method of the anti-ultraviolet polyester fiber masterbatch provided by the invention comprises the following steps: to particle diameter is the TiO of 20nm-50nm 2 and 100-300nm TiO 2 According to the mass ratio of 25%-100%: 0%-75%, the nano-anti-ultraviolet powder material is mixed; the nano-anti-ultraviolet powder material, coupling agent, antioxidant, and ester are mixed according to the mass ratio of 20%- 30%: 2.7%-2.85%: 0.15%-0.3%: 77%-67% Stir and mix, and form UV-resistant polyester fiber masterbatch after granulation.

[0024] Through the preparation method of anti-ultraviolet polyester fiber masterbatch provided by the invention, TiO 2 The particle size of the particles is controlled at 20-50nm or TiO with different particle sizes 2 The powder is mixed in a certain mass ratio, which can effectively reduce the TiO 2 The agglomeration effect of powder particles; on the other hand, in the preparation process of master...

Embodiment 1

[0040] 1. Preparation of UV-resistant polyester fiber masterbatch

[0041] First, TiO with a particle size of 20 nm 2 Put it into a drying oven with a temperature of 80° C., and dry it for 8 hours. Then, the TiO 2 Mix with polyacrylamide surface dispersant at a mass ratio of 92%:8%, and disperse by mechanical grinding. Next, the dispersed TiO 2 , titanate coupling agent, antioxidant IR1010, and PET according to the mass ratio of 20%:2.85%:0.15%:77% after high-speed stirring and mixing, and then granulated by a twin-screw mixing extruder to form an anti-ultraviolet polyester fiber matrix grain.

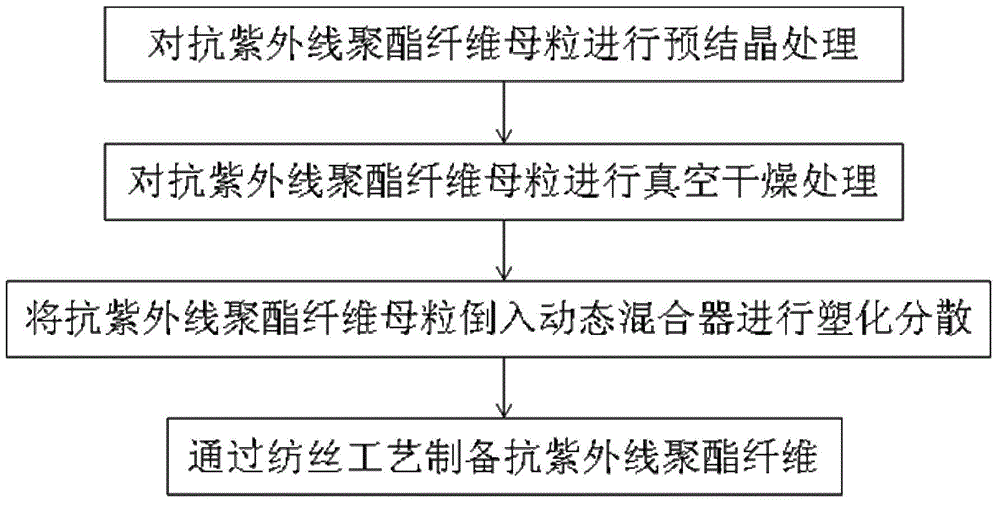

[0042] 2. Production of UV-resistant polyester fiber

[0043] Put the UV-resistant polyester fiber masterbatch in a drying oven at 75°C for 9 hours. Then, put the pre-crystallized anti-ultraviolet polyester fiber masterbatch into a vacuum drying device, and dry for 8 hours at a vacuum degree of less than 120 and a temperature of 125°C. Next, a dynamic mixer is installed on the c...

Embodiment 2

[0047] 1. Preparation of UV-resistant polyester fiber masterbatch

[0048] First, TiO with a particle size of 20 nm 2 and 100nm TiO 2 Mix with polyacrylamide surface dispersant at a mass ratio of 95%:5%, and disperse by mechanical grinding. Next, the TiO with a particle size of 20nm and 100nm after dispersion treatment 2 According to the mass ratio of 25%: 75%, mix and disperse the TiO 2 , silane coupling agent, antioxidant IR1010, and PET according to the mass ratio of 20%: 2.7%: 0.3%: 77%. After high-speed stirring and mixing, it is pelletized by twin-screw mixing extruder to form UV-resistant polyester fiber masterbatch.

[0049] 2. Production of UV-resistant polyester fiber

[0050] Put the anti-ultraviolet polyester fiber masterbatch in a drying oven at 80°C for 10 hours. Then, put the pre-crystallized anti-ultraviolet polyester fiber masterbatch into a vacuum drying device, and dry for 10 hours at a vacuum degree of less than 150 Pa and a temperature of 130°C. Next...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com