Solid electrolyte membrane as well as preparation process and application thereof

A solid electrolyte membrane and polymer technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of easy agglomeration of inorganic fillers, poor contact wettability, weak interaction, etc., to reduce the agglomeration effect and interface. The effect of low impedance and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a solid electrolyte membrane, and the specific preparation steps are as follows:

[0027] (1) 2g nano-SiO 2 Disperse into a three-necked flask filled with a mixed solution of absolute ethanol and distilled water with a volume ratio of 3:1, and disperse ultrasonically for 0.5 h; place the three-necked flask in a constant temperature oil bath, keep magnetic stirring in a nitrogen protective atmosphere, and heat up to After 80°C, add 0.2g of KH-560, and continue magnetic stirring at reflux temperature to make it fully react; after the reaction solution is centrifuged at high speed, use ethanol / distilled water to wash alternately for 2~3 times, and vacuum dry at 50°C for 8h to obtain the mass percentage 10% modified nano-SiO 2 , denoted as SiO 2 -KH560.

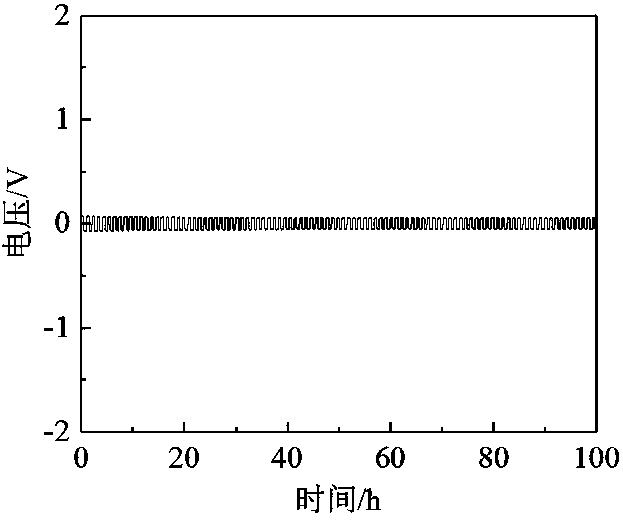

[0028] (2) Dissolve 3gPEO and 0.9gLITFSI in 40~70g of acetonitrile solvent, stir magnetically for 10h to obtain a mixed solution; add 0.18g of modified nano-SiO to the mix...

Embodiment 2

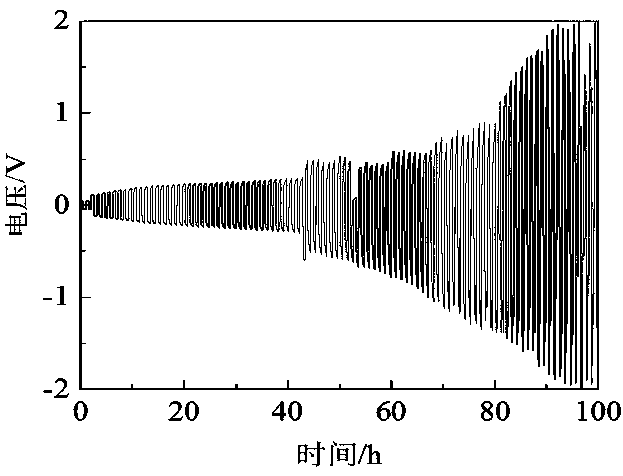

[0032] In this embodiment, a polymer solid electrolyte is used as the electrolyte of a high-performance all-solid-state lithium-ion secondary battery, and graphite is used as the positive electrode to prepare the battery. The specific preparation steps are as follows:

[0033] (1) Add 2gAl 2 o 3 Disperse into a three-necked flask filled with anhydrous ethanol and distilled water at a volume ratio of 3:1, and disperse ultrasonically for 0.5h; place the three-necked flask in a constant temperature oil bath, keep magnetic stirring in a nitrogen protective atmosphere, and heat up to 80°C Finally, add 0.4g of KH-570, and continue magnetic stirring at the reflux temperature to make it fully react; after the reaction solution is centrifuged at high speed, use ethanol / distilled water to wash alternately for 2~3 times, and vacuum dry at 50°C for 8h to obtain a mass percentage of 20 % modified Al 2 o 3 , denoted as Al 2 o 3 -KH570.

[0034] (2) Dissolve 3gPEO and 0.9gLiBOB in 40~7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com