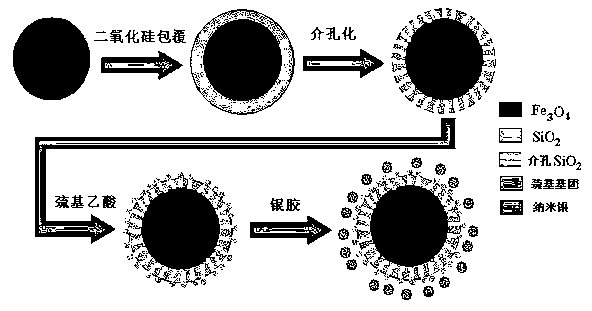

Preparation method of nanosilver and sulfydryl jointly modified magnetic microspheres

A magnetic microsphere and sulfhydryl modification technology, applied in the field of magnetic materials, can solve the problems of magnetic and other physical and chemical properties being easily affected by the external environment, uneven particle size distribution of magnetic microspheres, and high raw material cost, and achieve excellent antibacterial properties and regeneration properties. , Reduce the agglomeration effect, the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Magnetic Fe 3 o 4 Preparation of microsphere particles: Weigh 5g of anhydrous ferric chloride and add it to 80mL of glycerol solvent, then add sodium hexametaphosphate with an equimolar number to ferric chloride, treat with ultrasonic waves with a frequency of 20kHz for 30min, and stir The speed is 1000 rev / min, magnetically stirred for 1 hour until a uniform mixed system is obtained, poured into a PTFE-lined reaction kettle with a volume of 100mL, then placed in a drying oven, and reacted at a constant temperature of 220°C for 6 hours , after cooling to room temperature, the precipitate was repeatedly washed with absolute ethanol and distilled water until the pH of the washing solution was 7, and dried in vacuum under the condition of a vacuum of -0.1Mpa to obtain Fe 3 o 4 Magnetic microspheres;

[0031] 2) SiO2 2 Preparation of coated magnetic microspheres: the Fe obtained in step 1) 3 o 4 Place 0.5g of magnetic microspheres evenly in a sodium hexametaphospha...

Embodiment 2

[0036] 1) Magnetic Fe 3 o 4 Preparation of microsphere particles: Weigh 60g of ferric chloride hydrate and add it to 400mL of ethylene glycol solvent, then add ethylenediamine which is 3 times the molar number of ferric chloride, ultrasonic for 30min, stirring speed is 1000 rpm, Stir magnetically for 1 hour until a uniform mixed system is obtained, pour it into a PTFE-lined reaction kettle with a volume of 500mL, and then place it in a drying oven, react at a constant temperature of 180°C for 36 hours, and cool to room temperature. Repeated washing with absolute ethanol and distilled water until the pH of the washing solution = 7, and vacuum drying under the condition of a vacuum degree of -0.08Mpa to obtain Fe 3 o 4 Magnetic microspheres;

[0037] 2) SiO2 2 Preparation of wrapped magnetic microspheres: Place 0.5 g of magnetic microspheres obtained in step 1 evenly in a disodium edetate solution with a mass concentration of 10 g / L, soak for 6 hours, filter, and then disper...

Embodiment 3

[0042] 1) Magnetic Fe 3 o 4 Preparation of microsphere particles: Weigh 2g of ferric nitrate hydrate and add it to 40mL of propylene glycol solvent, then add trisodium citrate with the same molar number as ferric nitrate, ultrasonic 30min, stirring speed is 1000rpm, magnetic stirring for 1 hour until Obtain a uniform mixed system, pour it into a polytetrafluoroethylene-lined reaction kettle with a volume of 50mL, then place it in a drying box, and react at a constant temperature of 190°C for 20 hours. After cooling to room temperature, the precipitate is washed with absolute ethanol and Repeated washing with distilled water until the pH of the washing solution = 7, and vacuum drying under the condition of a vacuum degree of -0.08Mpa to obtain Fe 3 o 4 Magnetic microspheres;

[0043] 2) SiO2 2 Preparation of wrapped magnetic microspheres: Place 0.5 g of magnetic microspheres obtained in step 1 evenly in a disodium edetate solution with a mass concentration of 30 g / L, soak f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com