Five-axis linkage laser magnetorheological composite polishing machining device and using method thereof

A processing device and five-axis linkage technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as surface cracks and subsurface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

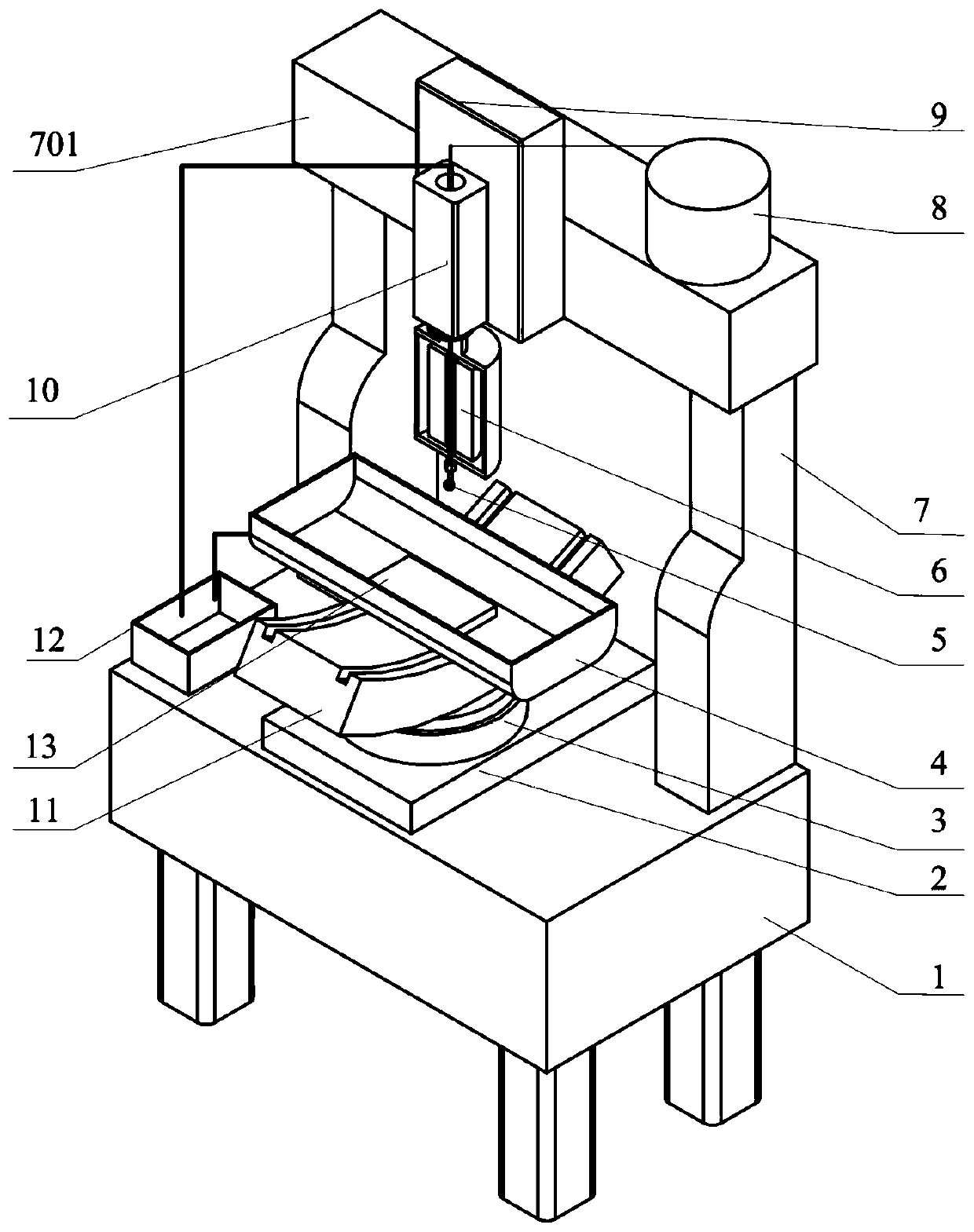

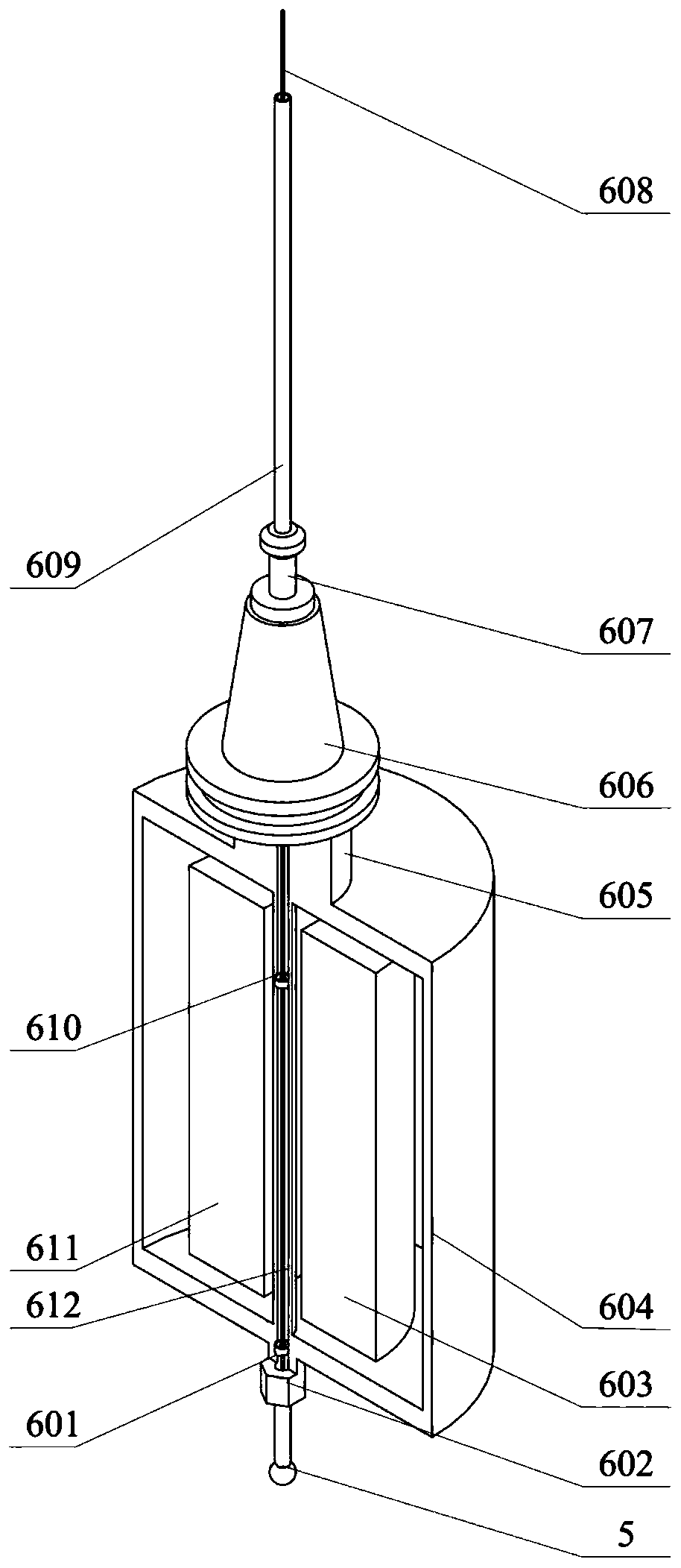

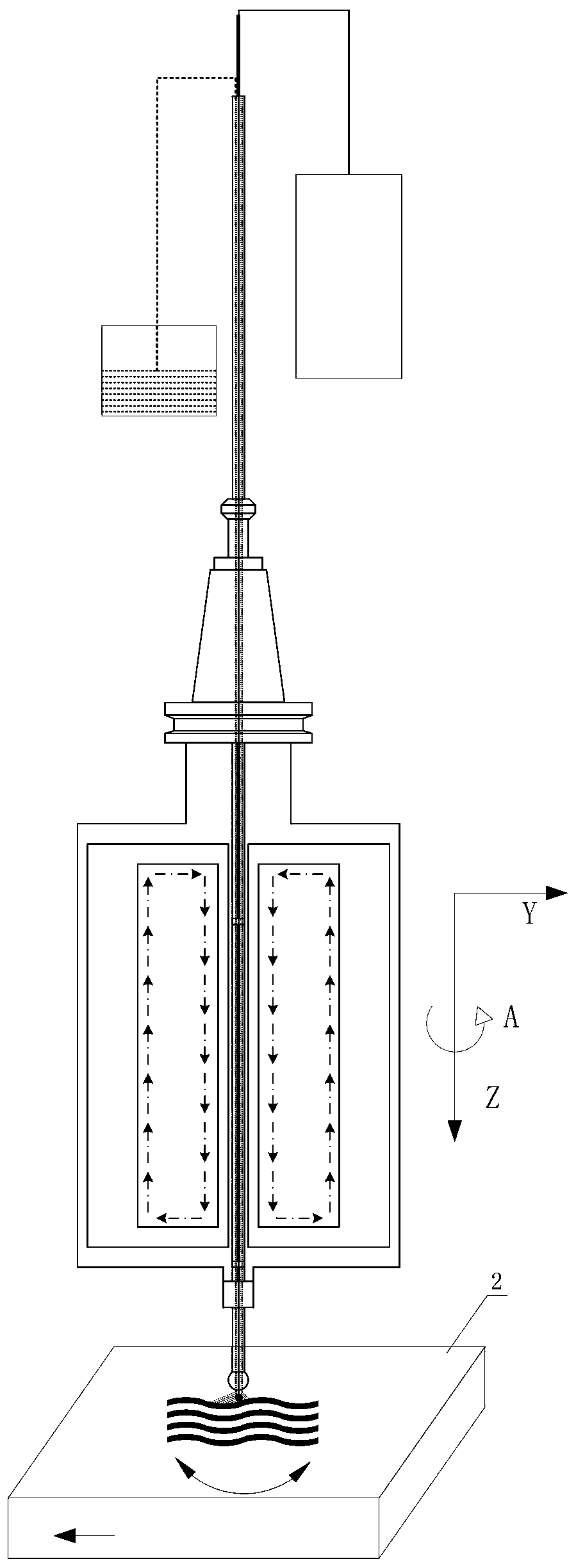

[0028] As shown in the figure, a five-axis linkage laser magneto-rheological compound polishing processing device includes a vibration isolation platform 1, a guide rail 2 in the X-axis direction, a rotary table 3, a magnetorheological liquid receiving tank 4, a hollow polishing head 5, a laser magnetic rheological spindle 6, gantry support 7, fiber laser 8, Z guide rail 9, magnetorheological spindle mounting part 10, swing table 11 and liquid recovery tank 12, the vibration isolation platform 1 has a vibration isolation platform with a size of 1000mm*800mm The area is responsible for carrying the weight of the overall device and isolating the influence of the ground on the ultra-precision machining process of five-axis linkage laser magnetorheological composite polishing. The middle part of the upper surface of the vibration isolation platform 1 is connected with the X-axis direction guide rail 2, and the upper part of one side of the vibration isolation platform 1 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com