Environment-friendly polyethylene compatilizer and preparation method thereof

A polyethylene and compatibilizer technology, applied in the polymer field, can solve the problems of unfavorable environmental protection and health, maleic anhydride is irritating, and affects the normal use of products, etc., and achieves excellent processing stability, low residue, good Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

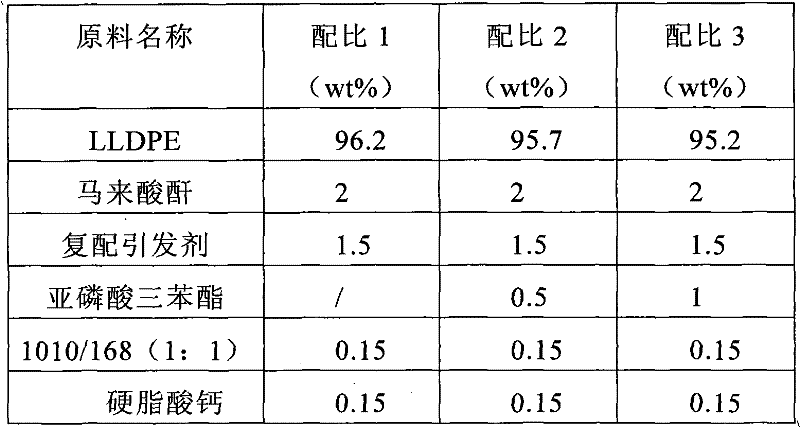

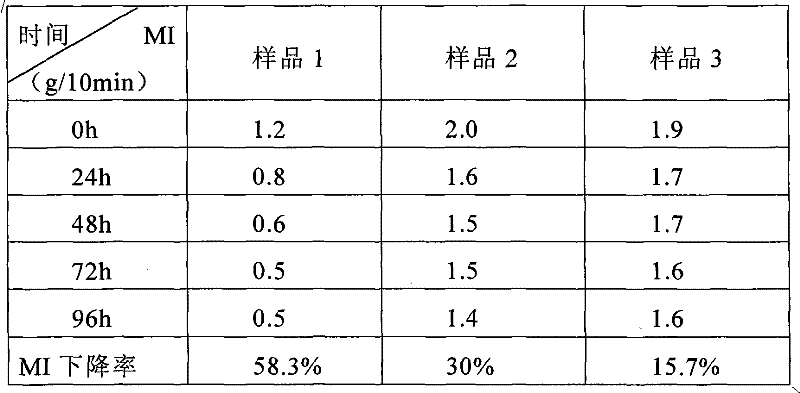

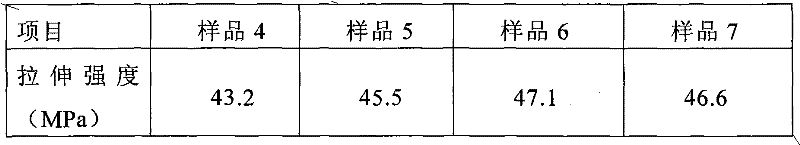

[0035] The polyethylene uses LLDPE imported from South Korea, the initiator uses 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, the antioxidant is 168 and 1010 from CIBA Company, and the lubricant uses stearin Calcium acid, maleic anhydride is used as functional monomer. Processed by traditional technology, put the above components into the high mixer according to the proportion and mix for 3-5 minutes, discharge the material, and then extrude and granulate with the screw extruder, the processing temperature is 80-200 ℃, the screw speed is 450 rpm.

Embodiment 2

[0037] The polyethylene is LLDPE imported from South Korea, and the initiator is a compound of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and bis-tert-butylperoxycumene, with a ratio of 2:3, the functional monomer is maleic anhydride, the antioxidant is CIBA 168 and 1010, the lubricant is calcium stearate, and the anti-crosslinking agent is triphenyl phosphite. Processed by traditional technology, put the above components into the high mixer according to the proportion and mix for 3-5 minutes, discharge the material, and then extrude and granulate with the screw extruder, the processing temperature is 80-200 ℃, the screw speed is 450 rpm.

Embodiment 3

[0039] The polyethylene is LLDPE imported from South Korea, and the initiator is a compound of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and bis-tert-butylperoxycumene, which has a single function The body uses maleic anhydride, the antioxidants are CIBA 168 and 1010, the lubricant uses calcium stearate, and the anti-crosslinking agent uses triphenyl phosphite. Put the above components into the high mixer according to the proportion and mix them for 3-5 minutes, discharge the material, and extrude it with a twin-screw extruder. Granules, the processing temperature is 80-200°C, the screw speed is 450 rpm, and the ultrasonic power is 400W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com