Chromium-molybdenum steel plate having excellent creep strength and method for manufacturing same

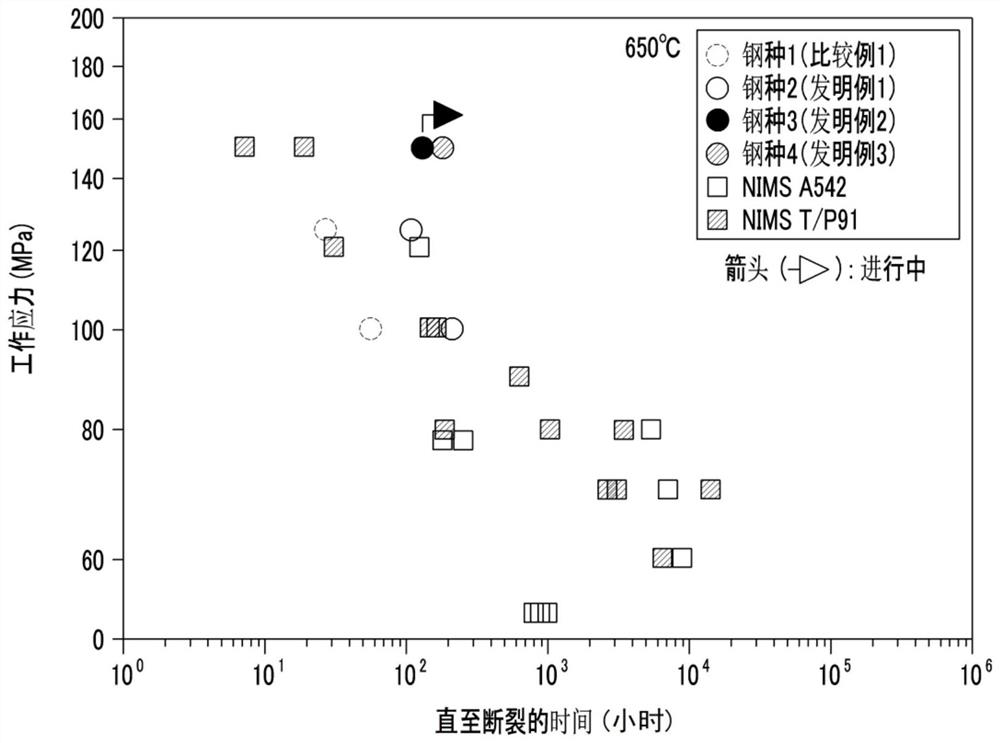

A creep strength and steel plate technology, applied in the field of chromium molybdenum steel plate and its preparation, can solve the problem of impossible mass production, and achieve the effect of excellent high temperature creep life and long creep life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

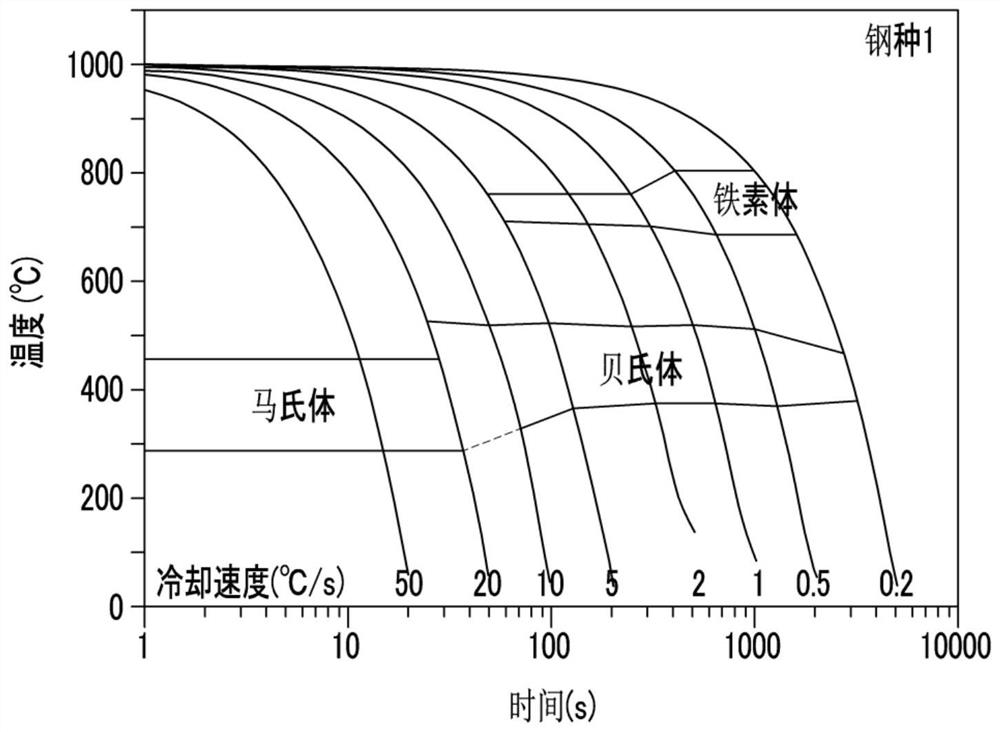

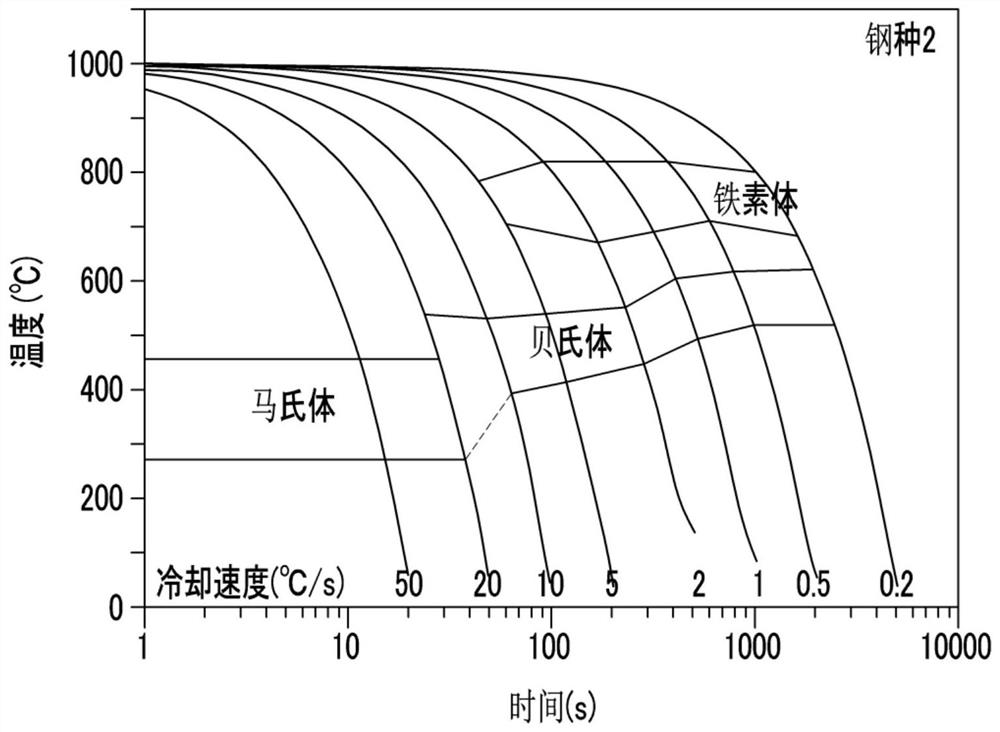

[0084] The preparation method of the precipitation-solidified chromium-molybdenum steel plate with excellent creep strength of the present invention comprises the following steps: hot-rolling the steel billet having the above-mentioned composition, so that the finish rolling temperature becomes above Ar3 to prepare the hot-rolled steel plate and then cooling; The cooled hot-rolled steel sheet is reheated in the temperature range of 900°C to 1200°C for 1t to 3t minutes [t (mm) is the thickness of the hot-rolled steel sheet] to austenitize the hot-rolled steel sheet; Quenching the austenitized hot-rolled steel sheet to normal temperature; and tempering the rapidly cooled hot-rolled steel sheet at a temperature range of 675-800° C. for 30-120 minutes.

[0085] First, in the present invention, a steel slab having the above composition is hot-rolled so that the finishing temperature becomes Ar3 or higher to obtain a hot-rolled steel sheet. The reason for hot rolling in the austenit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com