Forged aluminum alloy and manufacturing method for the same

A manufacturing method, technology of aluminum alloys, applied in the direction of manufacturing tools, metal processing equipment, furnace types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

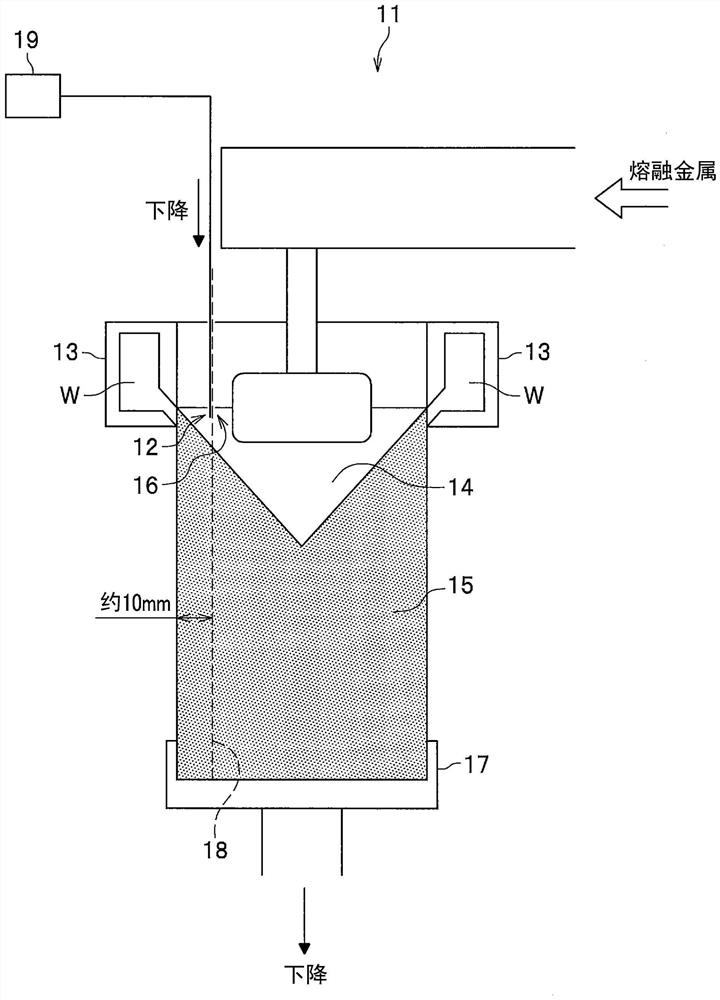

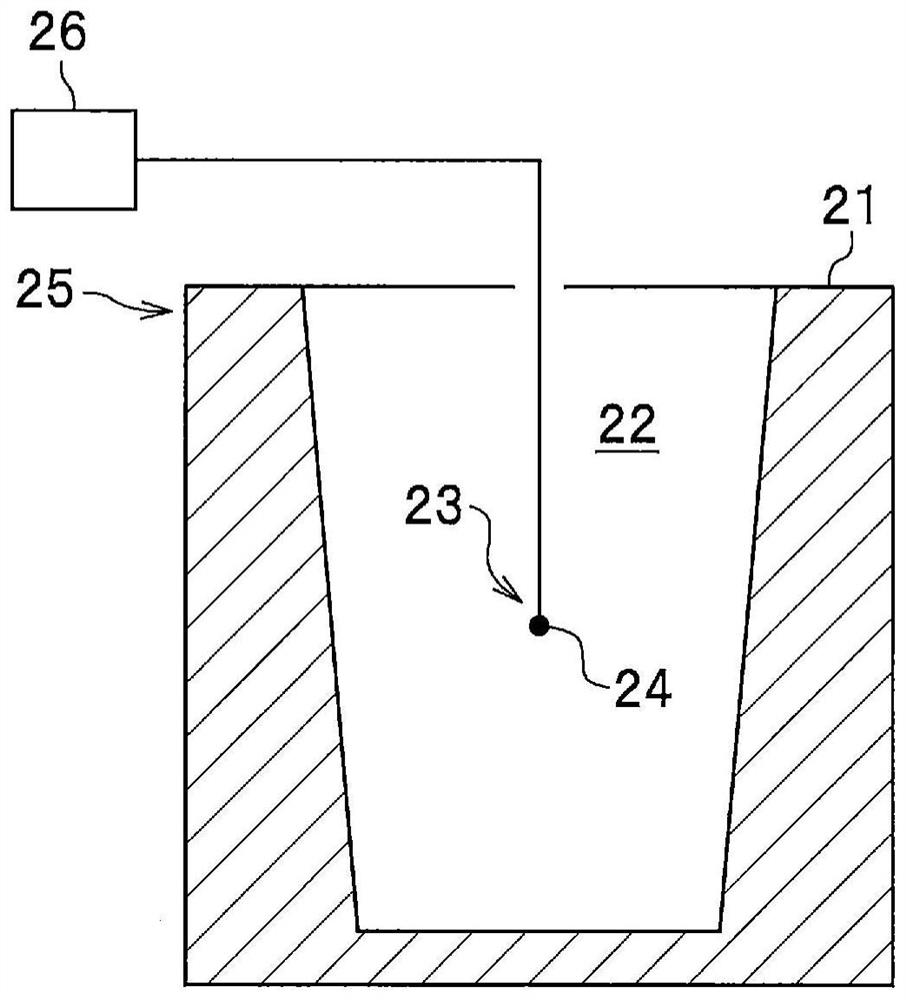

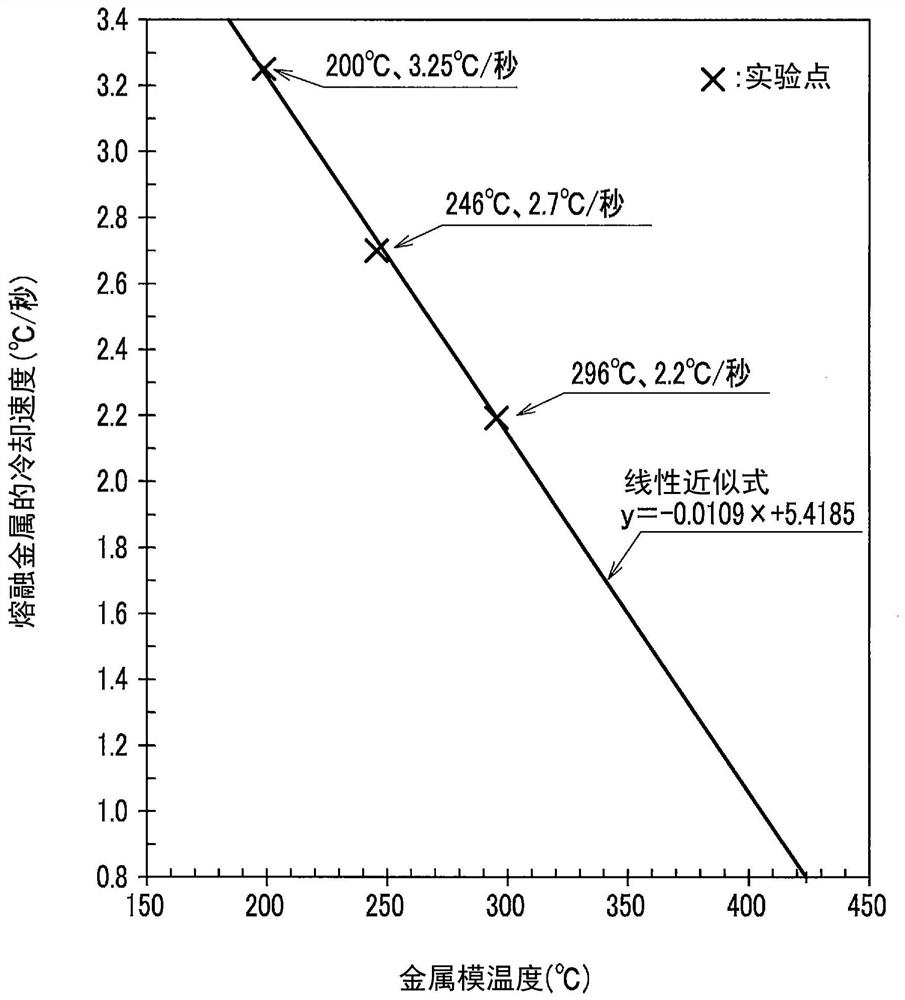

Embodiment Construction

[0024] Hereinafter, one embodiment of the present invention will be described with reference to the drawings as appropriate. In addition, since the drawings referred to in the following description schematically show one embodiment of the present invention, the proportions, intervals, and positional relationships of components may be exaggerated or part of the components may be omitted. "-" described in this specification is used in the meaning which has the numerical value described before and after that as a lower limit and an upper limit. The upper limit or lower limit described in the classification in this specification may be replaced by the upper limit or lower limit described in other classifications, or may be replaced by the numerical values shown in the examples.

[0025] [aluminum alloy forging materials]

[0026] First, an embodiment of an aluminum alloy forged material will be described.

[0027] The aluminum alloy forged material according to the present emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average equivalent circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com