Method for producing polyacetal resin composition

A polyacetal resin and a technology for a manufacturing method, which are applied in the field of manufacturing polyacetal resin compositions, can solve problems such as improvement, insufficient adhesion, and lack of activity of polyacetal resins, and achieve excellent creep properties, mechanical properties, and mechanical properties. Excellent effect

Active Publication Date: 2022-04-08

POLYPLASTICS CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, polyacetal resin lacks reactivity, and glass-based inorganic fillers also lack reactivity. Therefore, simply blending glass-based inorganic fillers with polyacetal resins and melting and kneading will result in poor adhesion between the two. Insufficient, in many cases, the expected improvement in mechanical properties cannot be obtained

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

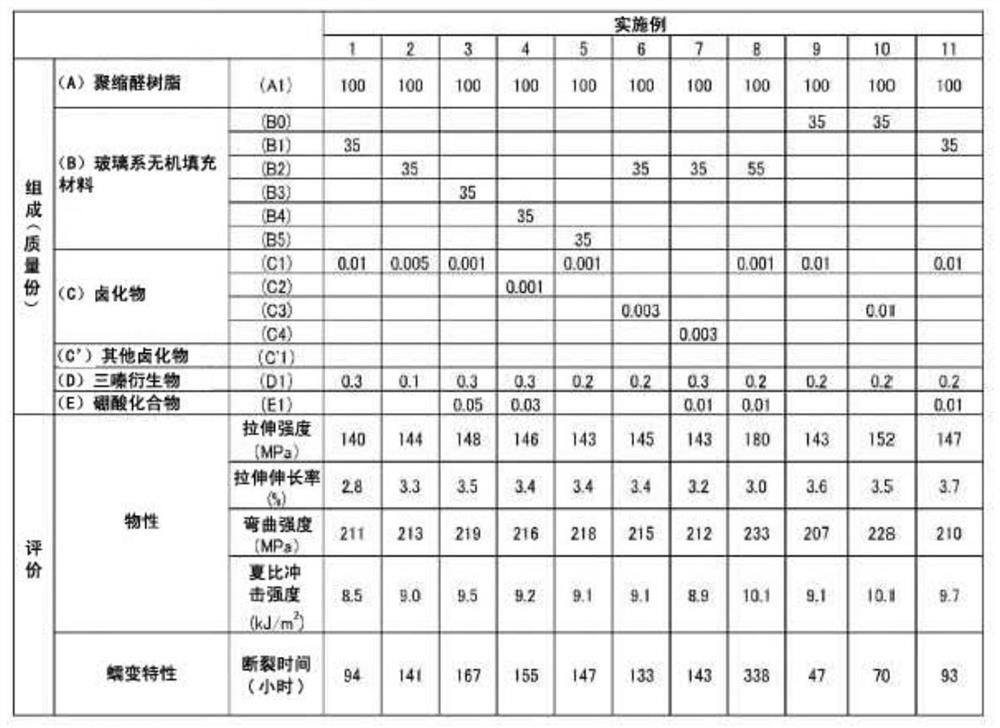

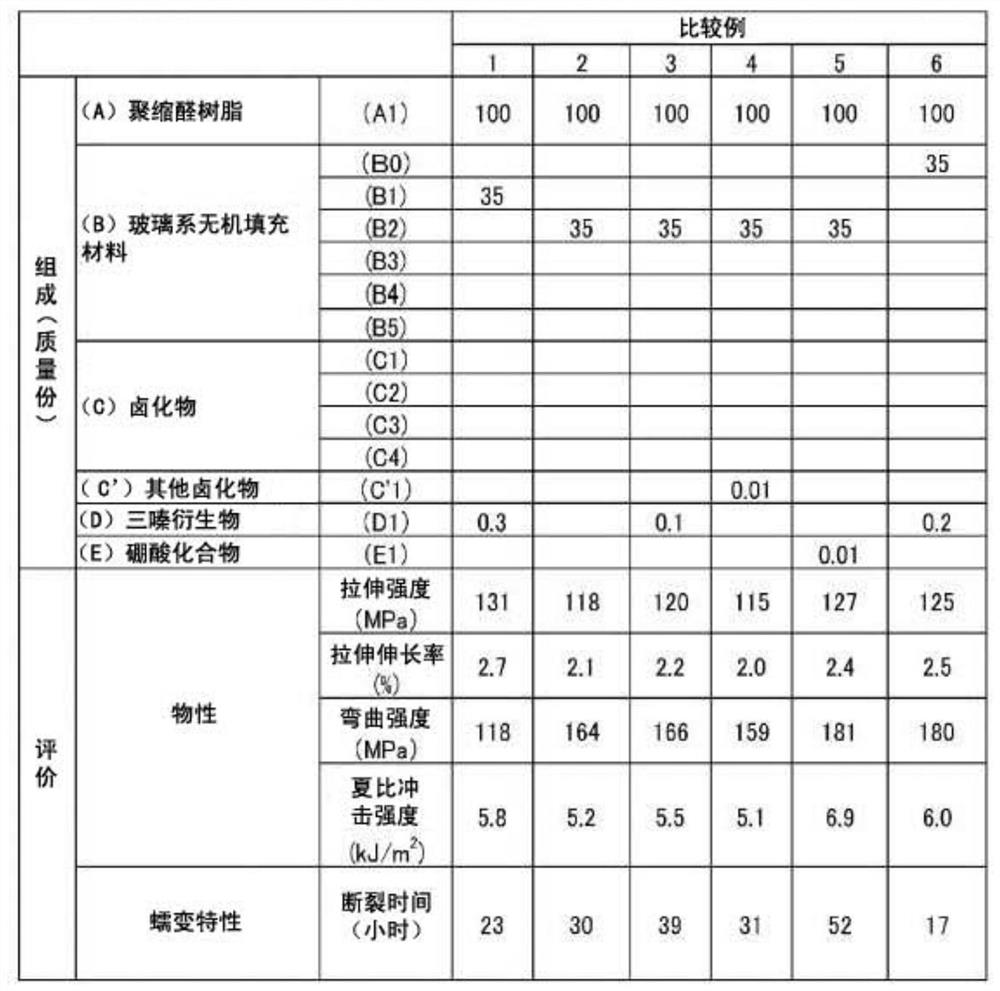

[0082] Hereinafter, although an Example is shown and this invention is demonstrated further concretely, this invention is not limited to the following Example at all. In addition, unless otherwise indicated, each evaluation was performed in the environment of 23 degreeC55%RH.

[0083]

[0084] In Table 1 and Table 2, various materials are as follows.

[0085] [(A) Polyacetal resin]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a method for producing a polyacetal resin composition. [Problem] To provide a method for producing a polyacetal resin composition having excellent mechanical properties such as tensile strength, tensile elongation, flexural strength, and impact resistance, particularly excellent creep properties. [Solution] A method for producing a polyacetal resin composition, wherein (B) a glass-based inorganic filler obtained by surface treatment with a silane coupling agent is added to 100 parts by mass of (A) polyacetal resin 1 mass part to 100 mass parts of the material, (C) 0.0001 mass part to 0.5 mass part of at least one halide selected from magnesium halide and ammonium halide, and (D) a triazine derivative having a nitrogen-containing functional group 0.002 mass parts or more and 10 mass parts or less are melt-kneaded and manufactured.

Description

technical field [0001] The present invention relates to a method for producing a polyacetal resin composition. Background technique [0002] Polyacetal resins have excellent properties in terms of mechanical properties, thermal properties, electrical properties, sliding properties, moldability, impact resistance, and dimensional stability of molded products, and are widely used as structural materials and mechanical parts in electrical equipment, Auto parts, precision machinery parts, etc. Furthermore, in order to improve the mechanical properties of polyacetal resins, such as strength and rigidity, it is known to mix reinforcing materials such as glass-based inorganic fillers. [0003] However, polyacetal resin lacks reactivity, and glass-based inorganic fillers also lack reactivity. Therefore, simply blending glass-based inorganic fillers with polyacetal resins and melting and kneading will result in poor adhesion between the two. Insufficient, the expected improvement i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L59/00C08K13/06C08K9/06C08K7/14C08K3/16C08K5/3492C08K3/38

CPCC08K3/16C08K3/38C08K5/3492C08K7/14C08K9/06C08K13/06C08K2003/166C08L59/00

Inventor 原科初彦胜地广和

Owner POLYPLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com