Film with moderate crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

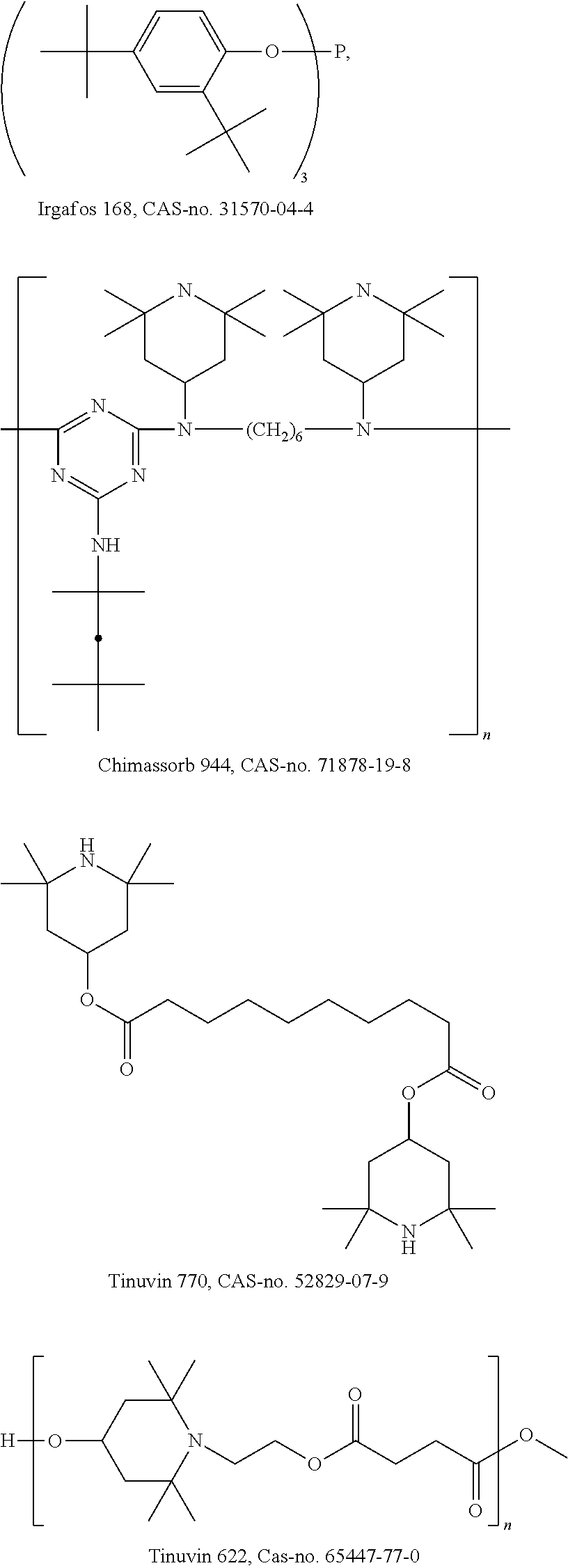

[0096]Materials

[0097]EVS (2.1%) MA (26%) Terpolymer produced by a high pressure tubular reactor in a conventional manner using conventional peroxide initiator, with a max temperature of 285° C., where ethylene monomers were reacted with vinyl trimethoxysilane (VTMS) and methylacrylate (MA) co-monomers amounts so as to yield 2.1 wt % vinyl trimethoxy silane content and 26 wt % MA content in the terpolymer. CTA was used to regulate MFR as well known for a skilled person. The melt flow rate (MFR2@190° C.) according to ISO 1133 (190° C., 2.16 kg) is 20 g / 10 min and a melting point of 85° C.

[0098]Compounding of the Blends

[0099]The different compounds were compounded on a pilot scale extruder (Prism TSE 24TC). The obtained mixture was melt mixed in conditions given in the table below and extruded to a string and pelletized.

TABLE 1Extruder setting for produced materials.Set Values Temperatures (° C.)ExtruderZone 1Zone 2Zone 3Zone 4Zone 5Zone 6rpmoutputpressure120° C.140° C.140° C.140° C.13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com