Ferritic heat-resistant steel and method for production thereof

A manufacturing method and heat-resistant steel technology, applied in the field of ferritic heat-resistant steel and its manufacturing, can solve the problems of reduced strength improvement effect, large ferritic heat-resistant steel, and inability to provide creep strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

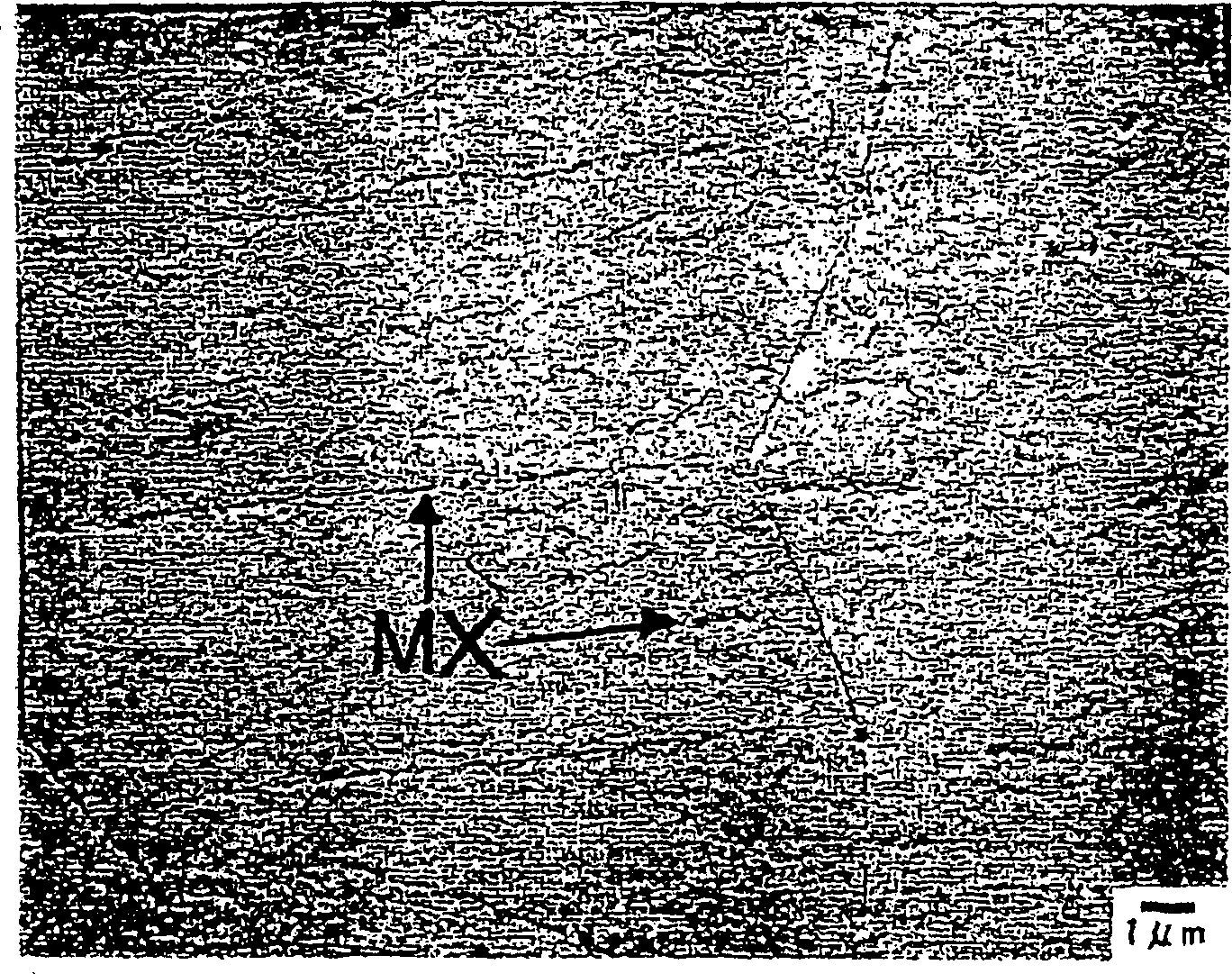

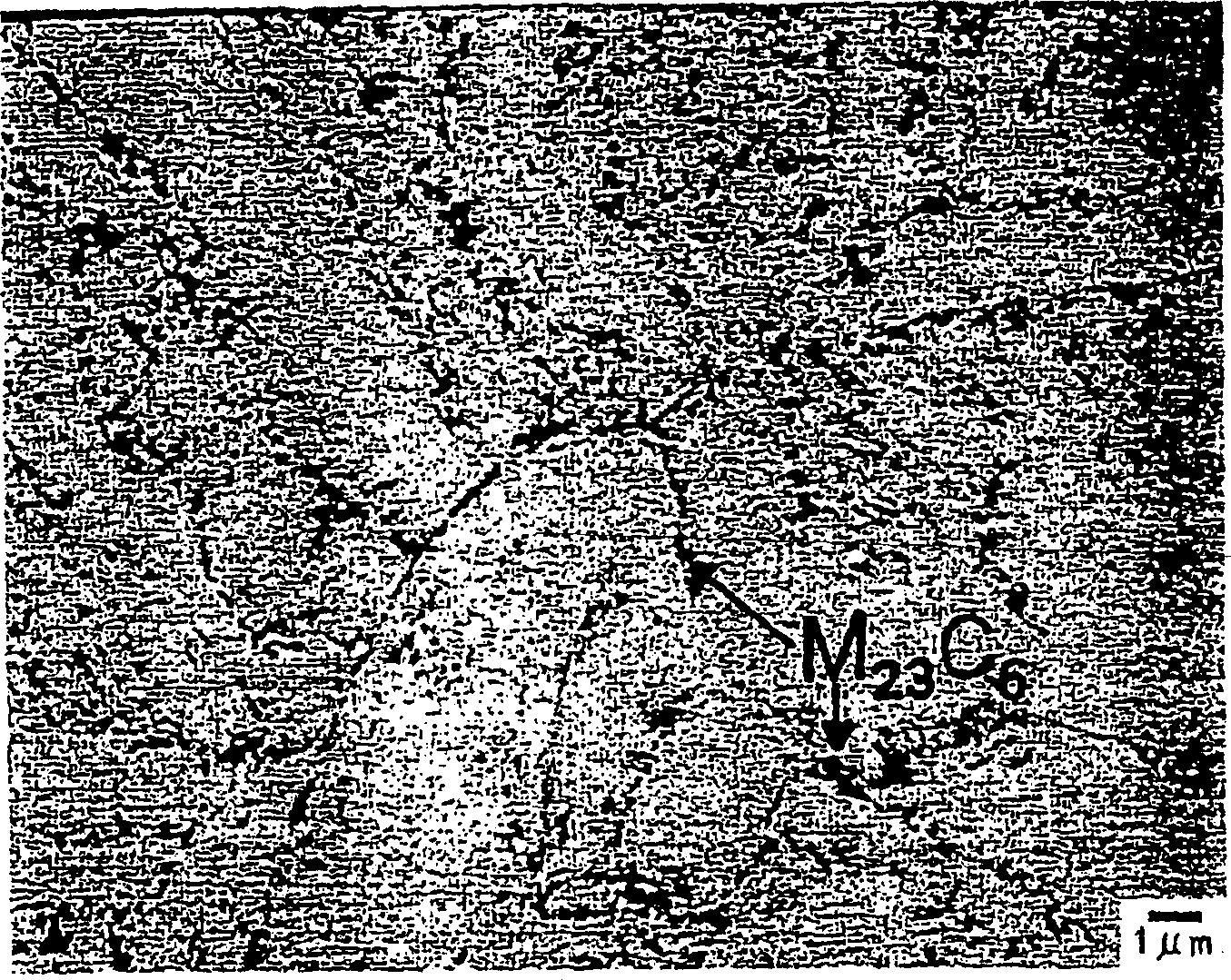

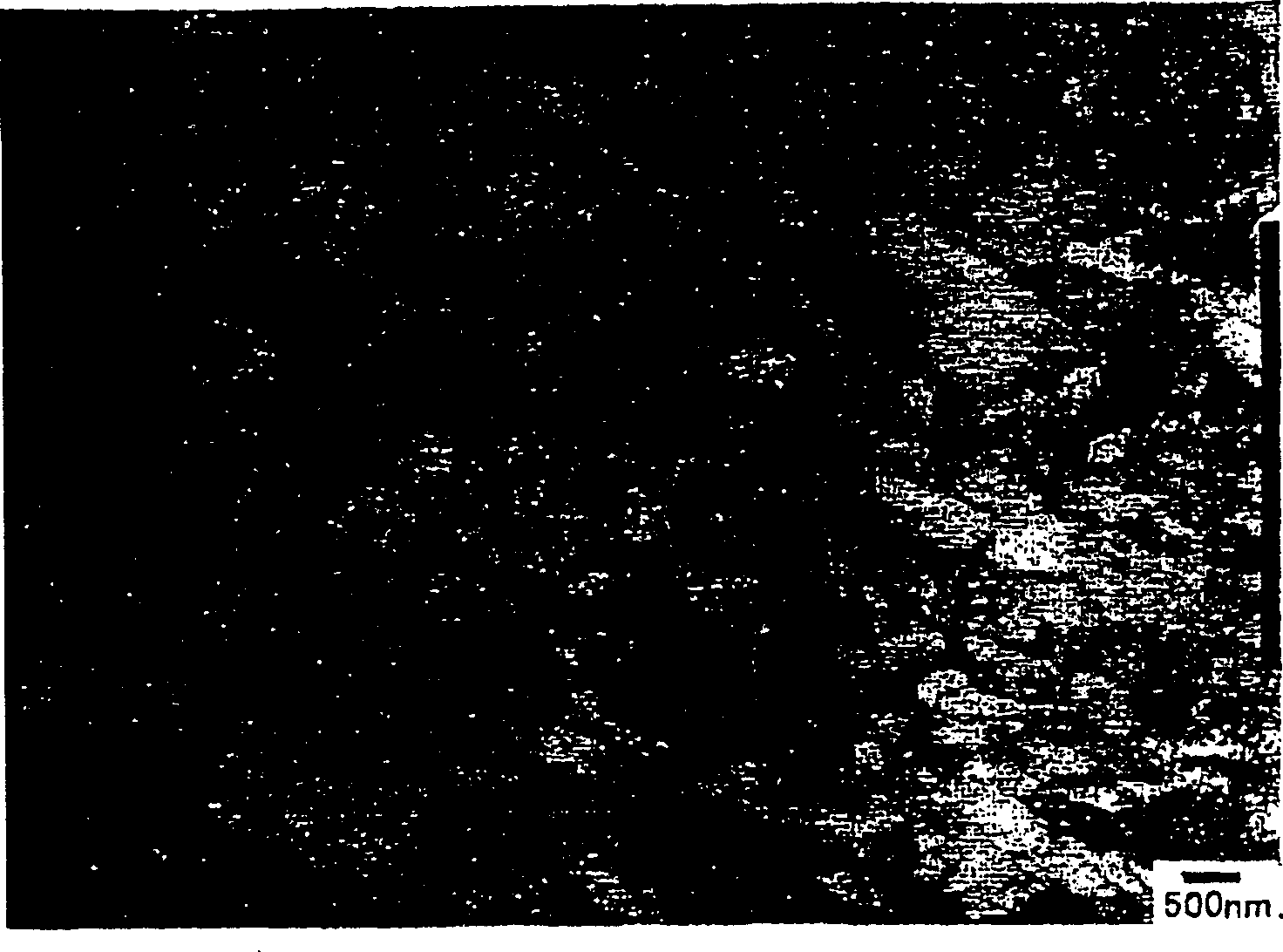

Image

Examples

Embodiment 1~4

[0040] (Examples 1-4, Comparative Examples 5-8)

[0041] Eight types of heat-resistant steels were used as test materials, and their chemical compositions are shown in Table 1 below. Among them, No.1 to No.4 are heat-resistant steels within the chemical composition range of the present invention, and No.5 to No.8 are heat-resistant steels outside the chemical composition range of the present invention. In addition, Comparative Examples No. 5 and No. 6 are steels in which the amount of carbon added is outside the range of the carbon amount of the present invention. No. 6 steel is the same as that described in the aforementioned Japanese Patent No. 2948324 shown in the prior art. Steels of similar alloy phase. In addition, No. 7 steel is a steel in which the amount of cobalt added is outside the range of the amount of cobalt in the present invention, and is similar to the alloy described in JP-A-62-180039, which is known in the prior art. Furthermore, No. 8 steel is a steel wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com