Ni-BASED SUPERALLOY WITH EXCELLENT OXIDIZATION RESISTANCE AND CREEP PROPERTY AND METHOD OF MANUFACTURING THE SAME

a superalloy and creep technology, applied in the field of ni-based superalloys, can solve the problems that alloys cannot exhibit good creep properties and good oxidization resistance, and achieve excellent oxidization resistance and creep properties, enhance creep properties, and reduce the amount of chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0080]Hereinafter, the present invention will be described with reference to some examples. However, these examples are given by way illustration only and should not be construed in any way as limiting the invention.

[0081]Descriptions of details apparent to those skilled in the art will be omitted herein.

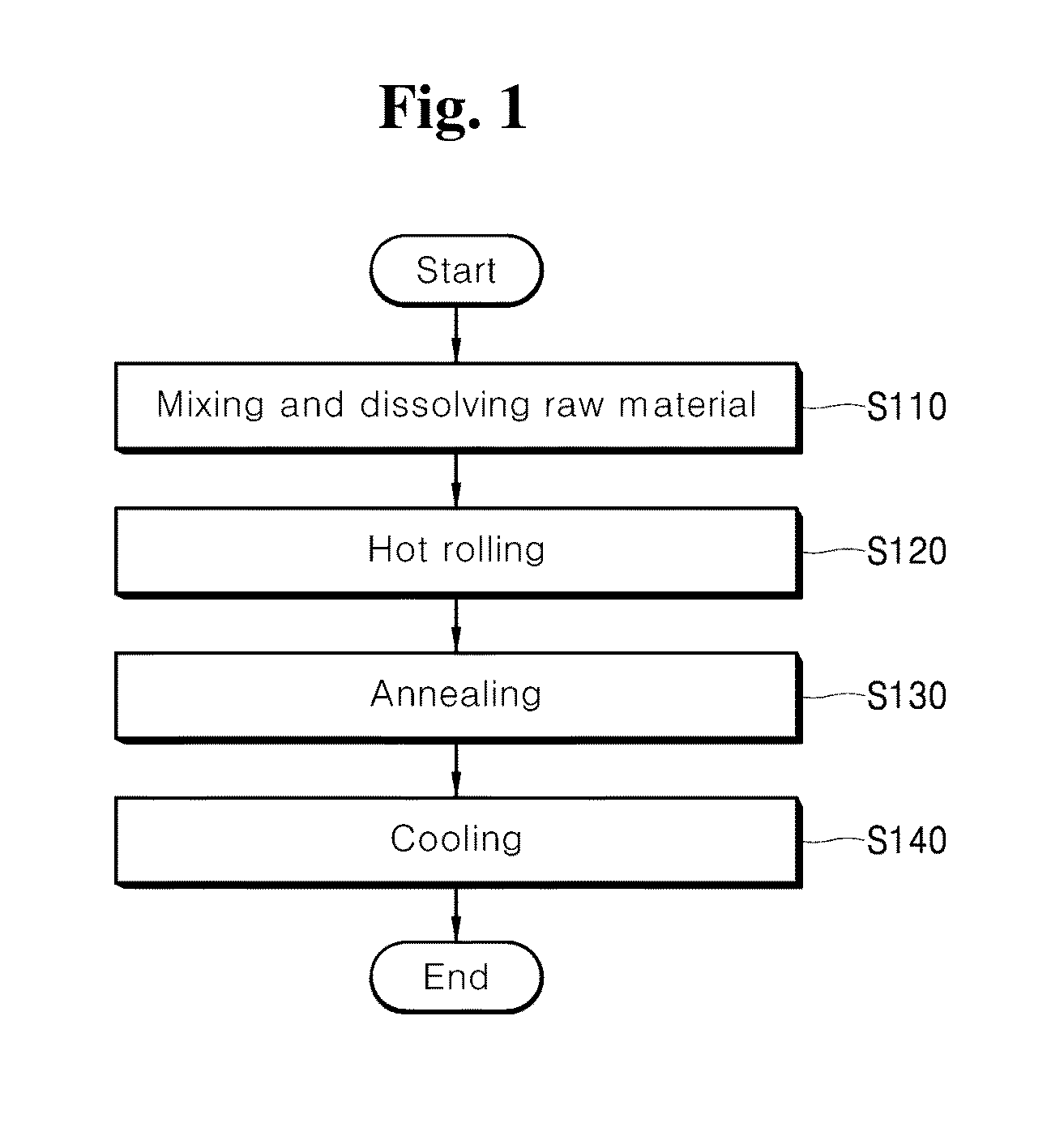

[0082]1. Manufacture of Sample

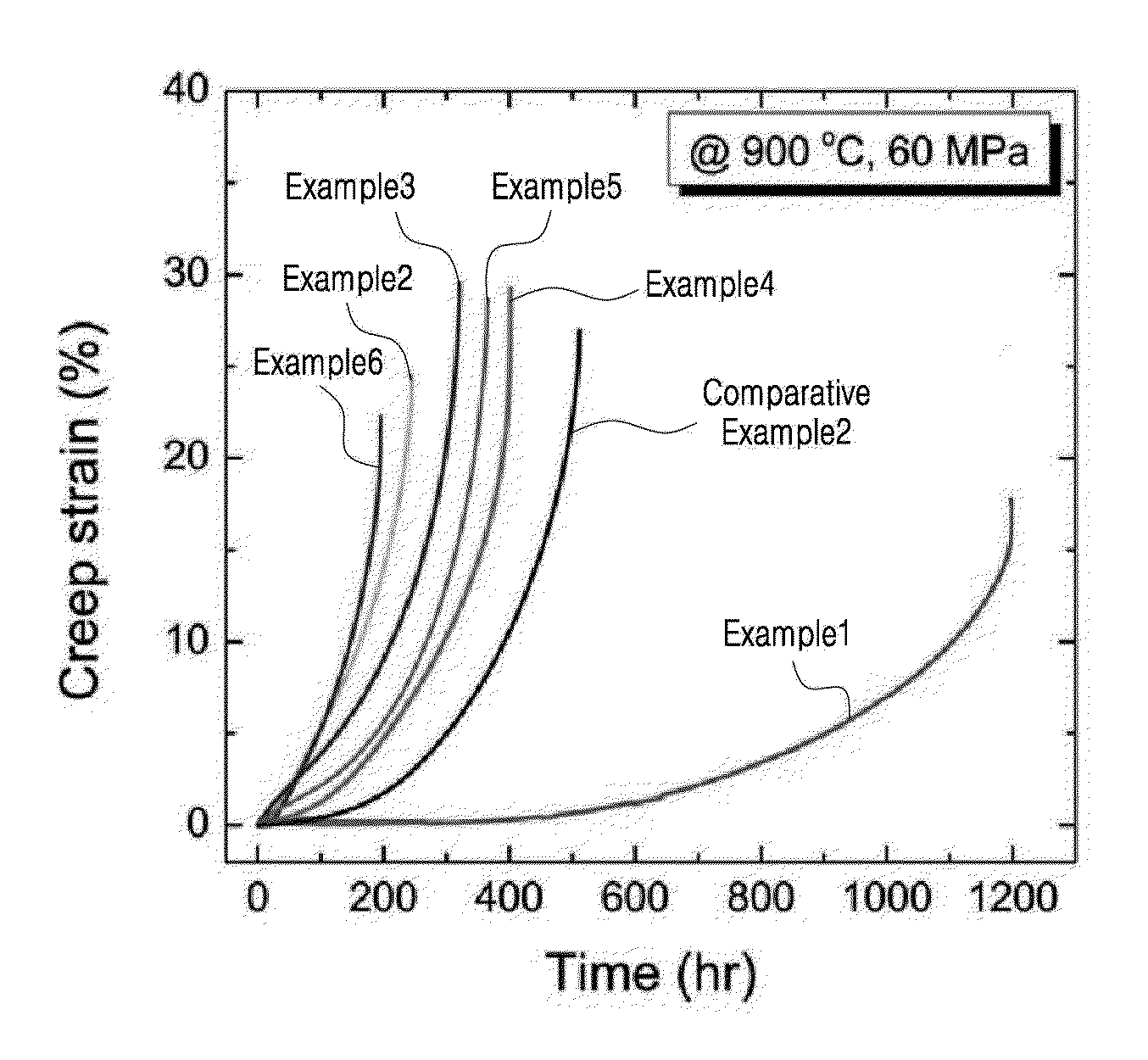

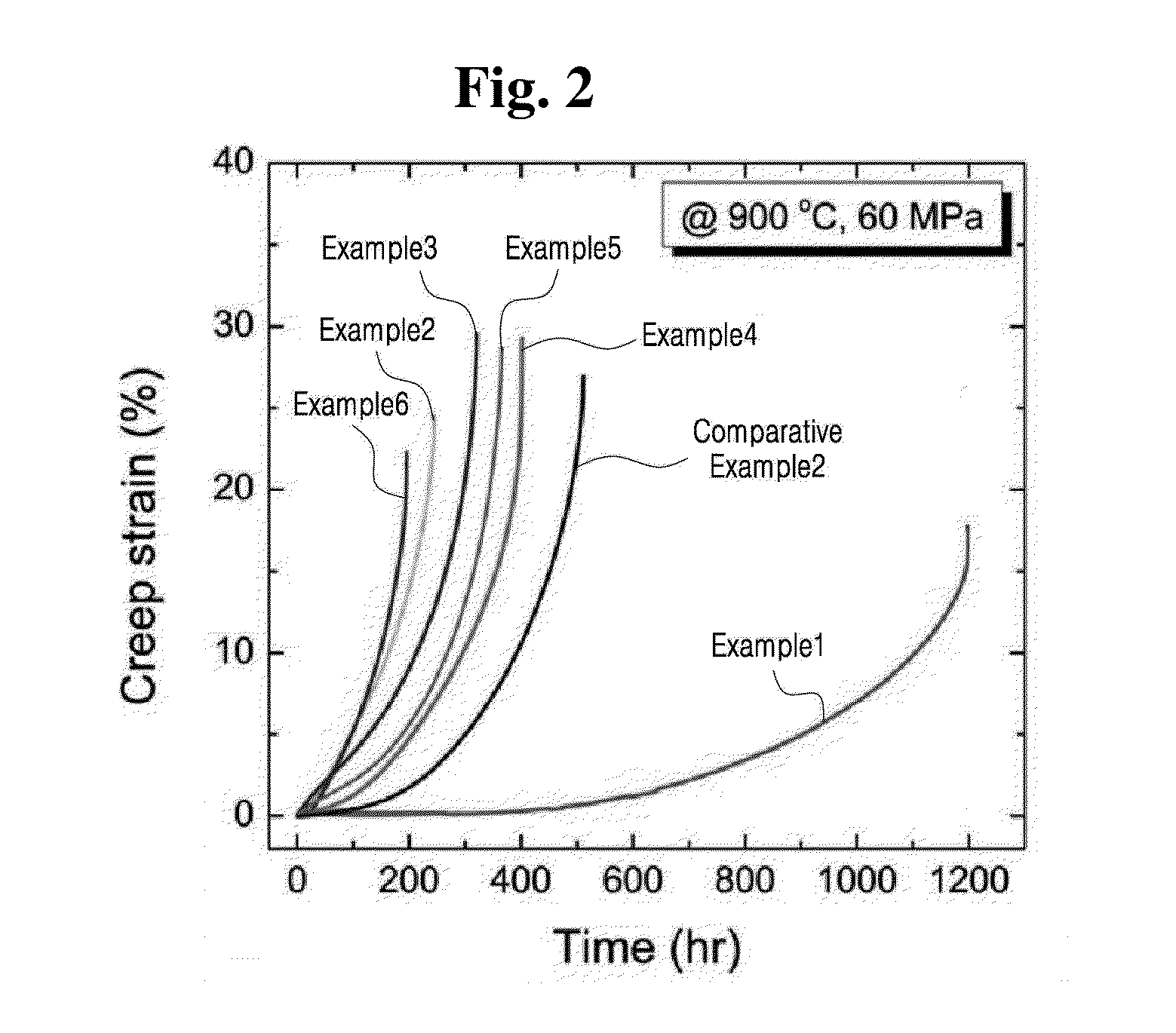

[0083]Samples of Examples 1 to 11 and Comparative Examples 1 to 3 were prepared according to compositions as listed in Table 1 and process conditions as listed in Table 2.

TABLE 1(unit: wt %)CrWMoMnSiAlLaCBFeCoTiNiExample 1211420.70.20.20.020.10.015———Bal.Example 2261620.80.30.50.020.10.015———Bal.Example 3231440.10.50.20.020.10.015———Bal.Example 4211420.70.20.20.040.040.005———Bal.Example 5261620.80.30.50.020.160.005———Bal.Example 6231440.10.50.20.040.040.005———Bal.Example 7211420.70.20.50.020.10.015———Bal.Example 8211420.70.20.80.020.10.015———Bal.Example 9211420.70.50.20.020.10.015———Bal.Example 10211420.70.50.50.020.10.015———Bal.Example 11211420.70.50.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com