Composition for low temperature

a technology of composition and low temperature, applied in the field of composition for low temperature, can solve the problems of reducing shear stability and difficulty in developing lubricant compositions that offer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

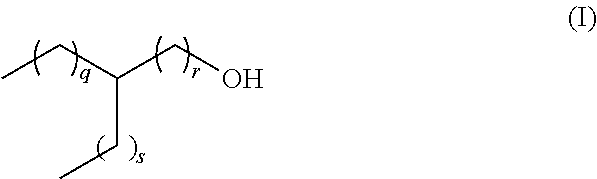

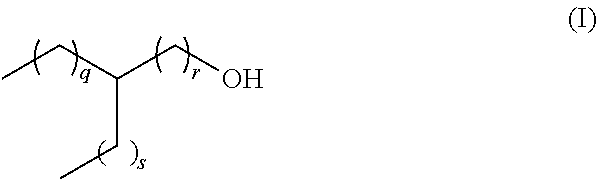

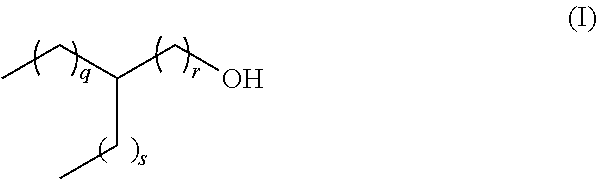

Image

Examples

examples

Methods

[0264]Measurement of the number average molecular weight Mn of polymers mentioned in the present invention has been carried out using the industrial standard DIN 55672.

[0265]The pour point of the lubricant compositions according to the present invention has been determined according to the established industrial standard DIN ISO 3016 (if not indicated otherwise).

[0266]The various kinematic viscosities of the lubricant compositions according to the present invention have been determined following established industry standards.

[0267]The kinematic viscosity at −30° C., 40° C. and 100° C., respectively, is determined according to the established industrial standard DIN 51562-1 (unless indicated otherwise).

[0268]The dynamic viscosity is determined based on DIN 51562-1 and further calculated by multiplication of the measured kinematic viscosity with the corresponding density.

[0269]The viscosity index has been determined according to the industrial standard DIN ISO 2909 (if not ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com