Acrylic thermally conductive composition, and thermally conductive sheet

An acrylic and composition technology, which is applied in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid device components, etc., can solve the problems of softness damage, difficulty in obtaining adhesion, etc., and achieve the suppression of outgassing , the effect of excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

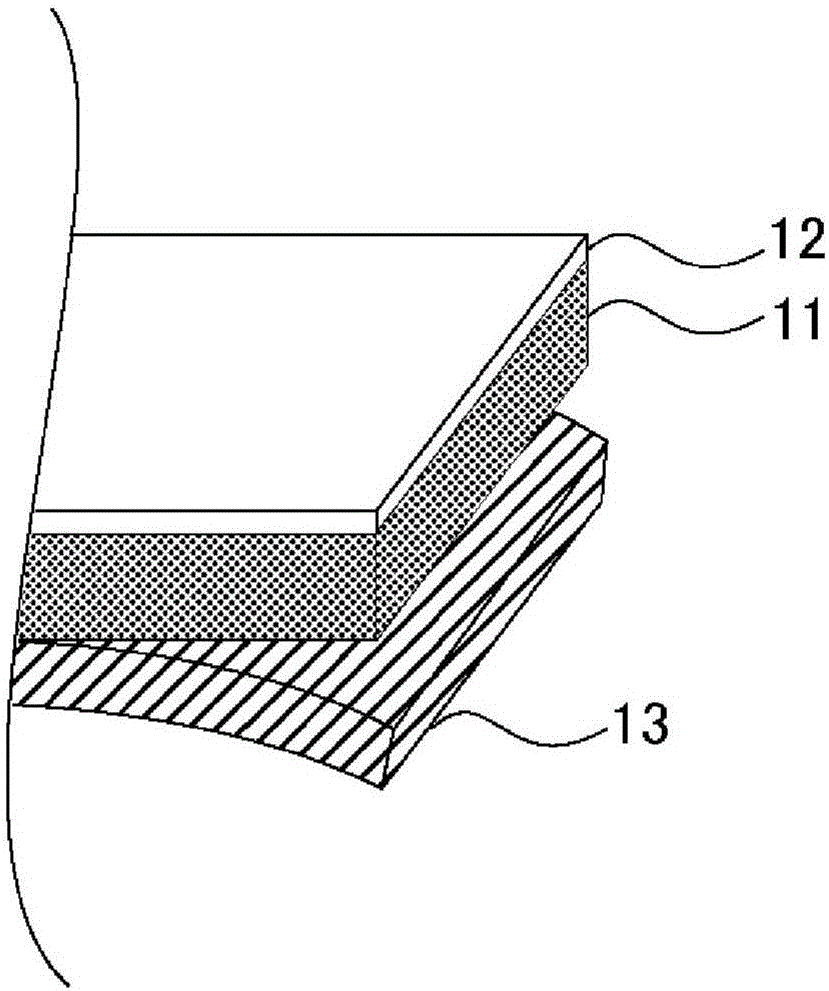

Image

Examples

Embodiment 1

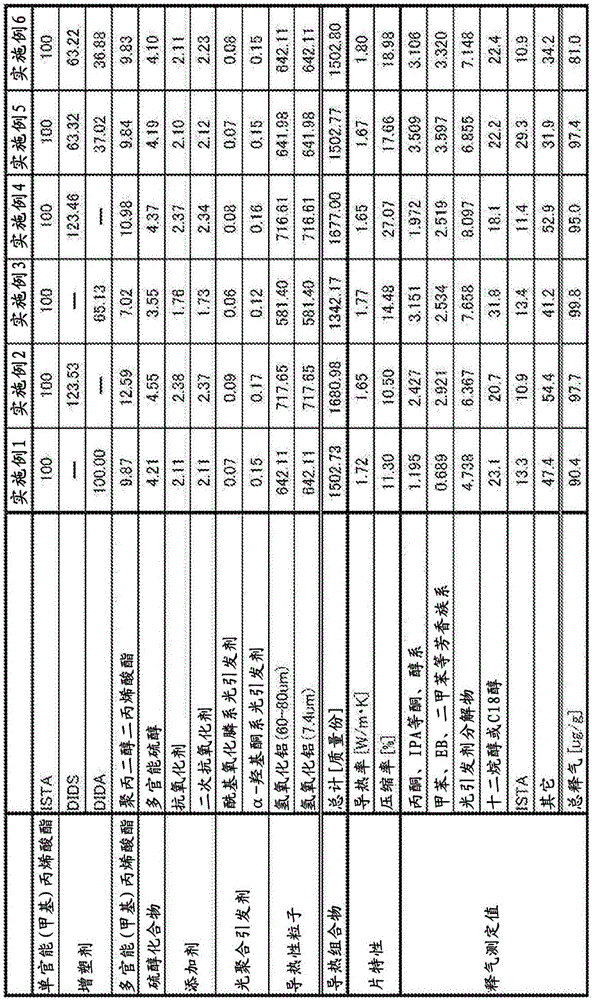

[0088] As shown in Table 1, 100 parts by mass of ISTA as monofunctional acrylate, 100.00 parts by mass of DIDA as adipate, 9.87 parts by mass of polypropylene glycol diacrylate, 4.21 parts by mass of polyfunctional thiol, 2.11 parts by mass of antioxidant Parts by mass, 2.11 parts by mass of secondary antioxidant, 0.07 parts by mass of acylphosphine oxide-based photoinitiator, 0.15 parts by mass of α-hydroxyketone-based photoinitiator, 642.11 parts by mass of aluminum hydroxide with an average particle diameter (D50) of 60 to 80 μm , and 642.11 parts by mass of aluminum hydroxide having an average particle diameter (D50) of 7.4 μm were added to a mixer and kneaded to obtain an acrylic heat-conducting composition. Then, by the method described above, a thermally conductive sheet was obtained.

[0089] As shown in Table 1, the thermal conductivity of the thermally conductive resin layer in Example 1 was 1.72 W / m·K, and the compressibility was 11.30%. In addition, as a result of...

Embodiment 2

[0091] As shown in Table 1, 100 parts by mass of ISTA as monofunctional acrylate, 123.53 parts by mass of DIDS as sebacate, 12.59 parts by mass of polypropylene glycol diacrylate, 4.55 parts by mass of polyfunctional thiol, 2.38 parts by mass of antioxidant Parts by mass, 2.37 parts by mass of secondary antioxidant, 0.09 parts by mass of acyl phosphine oxide photoinitiator, 0.17 parts by mass of α-hydroxyketone photoinitiator, 717.65 parts by mass of aluminum hydroxide with an average particle diameter (D50) of 60 to 80 μm , and 717.65 parts by mass of aluminum hydroxide having an average particle diameter (D50) of 7.4 μm were added to a mixer and kneaded to obtain an acrylic heat-conducting composition. Then, by the method described above, a thermally conductive sheet was obtained.

[0092]As shown in Table 1, the thermal conductivity of the thermally conductive resin layer in Example 2 was 1.65 W / m·K, and the compressibility was 10.50%. In addition, as a result of measuring...

Embodiment 3

[0094] As shown in Table 1, 100 parts by mass of ISTA as monofunctional acrylate, 65.13 parts by mass of DIDA as adipate, 7.02 parts by mass of polypropylene glycol diacrylate, 3.55 parts by mass of polyfunctional thiol, 1.76 parts by mass of antioxidant Parts by mass, 1.73 parts by mass of secondary antioxidant, 0.06 parts by mass of acyl phosphine oxide photoinitiator, 0.12 parts by mass of α-hydroxyketone photoinitiator, 581.40 parts by mass of aluminum hydroxide with an average particle diameter (D50) of 60 to 80 μm , and 581.40 parts by mass of aluminum hydroxide having an average particle diameter (D50) of 7.4 μm were added to a mixer and kneaded to obtain an acrylic heat-conducting composition. Then, by the method described above, a thermally conductive sheet was obtained.

[0095] As shown in Table 1, the thermal conductivity of the thermally conductive resin layer in Example 3 was 1.77 W / m·K, and the compressibility was 14.48%. In addition, as a result of measuring t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com