Preparation method of double-layer Mxene film based on different interlayer spacing

A layer-spacing, double-layer technology is applied in the field of preparation of double-layer Mxene membranes, which can solve the problems of complex separation and preparation process, low membrane chemical stability, and high preparation requirements, and achieve high economic feasibility, easy preparation method, and low solute backmix small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

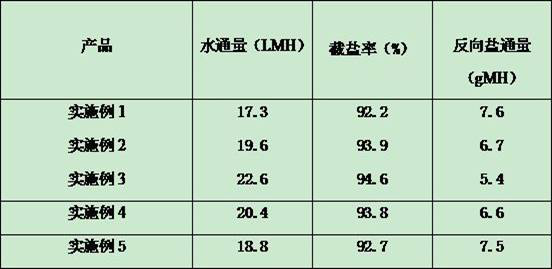

Examples

Embodiment 1

[0028] Bilayer Mxene films based on different interlayer spacings were prepared in the following manner:

[0029] 1) Mix HCl, LiF and Ti with a mass ratio of 10:1:1 3 AlC 2 They were added to the reactor in turn, heated and stirred at 30 °C for 24 h, and then the mixture in the reactor was transferred to a centrifuge tube, washed and centrifuged repeatedly, and then the washed clay-like precipitate was transferred to a large-mouth bottle for ultrasonic peeling and centrifugation. The supernatant is obtained as MXene monolayer nanosheet solution.

[0030] 2) Take a piece of PVDF membrane with a pore size of 0.22 μm and put it on the assembled suction filtration device, and mix the Mxene single-layer nanosheet solution obtained in step 1) with magnesium chloride and maleic acid, according to 1:0.5:0.5 equal volume The concentration ratios were mixed, vacuum filtered on the PVDF base membrane, and placed at 70° C. for 5 hours to obtain a Mxene membrane.

[0031] 3) Then take the...

Embodiment 2

[0033] Two-layer Mxene films based on different layer spacings were prepared in the following ways:

[0034] 1) HCl, LiF and Ti with a mass ratio of 12:1.2:1 3 AlC 2 Put them into the reactor one by one, heat and stir at 32°C for 30 hours, then transfer the mixture in the reactor to a centrifuge tube, wash and centrifuge repeatedly, and then transfer the washed clay-like precipitate to a jar for ultrasonic stripping and centrifugation. The supernatant is the MXene monolayer nanosheet solution.

[0035] 2) Take a piece of PVDF membrane with a pore size of 0.22 μm and put it on the assembled suction filtration device, and mix the Mxene single-layer nanosheet solution obtained in step 1) with magnesium chloride and maleic acid, according to 1:0.6:0.6 equal volume The concentration ratios were mixed, vacuum filtered on the PVDF base membrane, and placed at 72° C. for 5.2 hours to obtain a Mxene membrane.

[0036] 3) Then take the mixed solution of MXene solution, sodium chlorid...

Embodiment 3

[0038] Two-layer Mxene films based on different layer spacings were prepared in the following ways:

[0039] 1) HCl, LiF and Ti with a mass ratio of 15:1.4:1 3 AlC 2 Put them into the reactor one by one, heat and stir at 35°C for 36 hours, then transfer the mixture in the reactor to a centrifuge tube, wash and centrifuge repeatedly, and then transfer the washed clay-like precipitate to a jar for ultrasonic stripping and centrifugation. The supernatant is the MXene monolayer nanosheet solution.

[0040] 2) Take a piece of PVDF membrane with a pore size of 0.22 μm and put it on the assembled suction filtration device, and mix the Mxene single-layer nanosheet solution obtained in step 1) with magnesium chloride and maleic acid, according to 1:0.8:0.8 equal volume The concentration ratios were mixed, vacuum filtered on the PVDF base membrane, and placed at 75° C. for 5.5 hours to obtain a Mxene membrane.

[0041] 3) Then take the mixed solution of MXene solution, sodium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com