Patents

Literature

43 results about "Carboxylic acid reductase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This enzyme is also called aldehyde:(acceptor) oxidoreductase. This enzyme participates in pyruvate metabolism. It employs one cofactor, tungsten. White H, Strobl G, Feicht R, Simon H (1989). "Carboxylic acid reductase: a new tungsten enzyme catalyses the reduction of non-activated carboxylic acids to aldehydes".

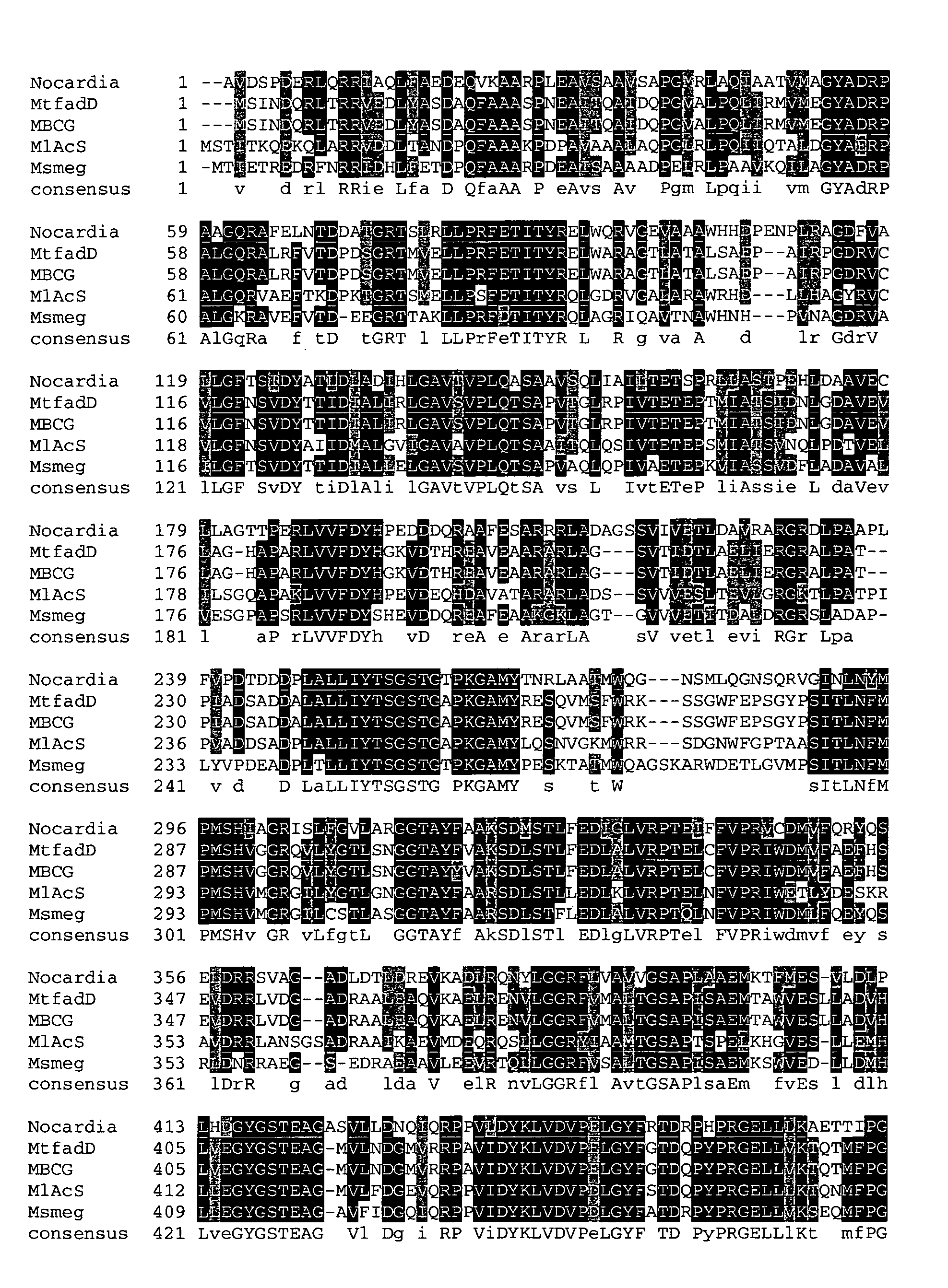

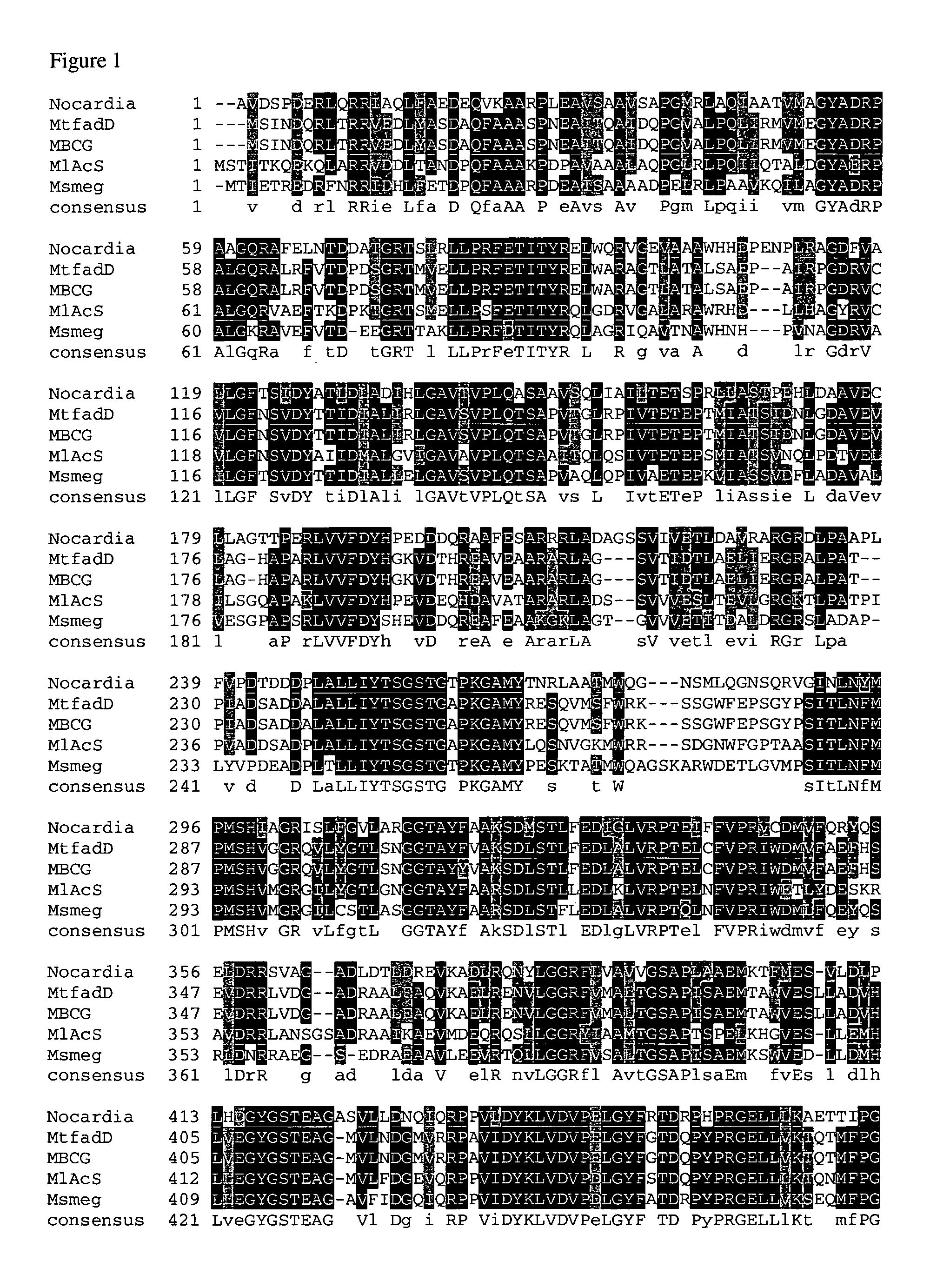

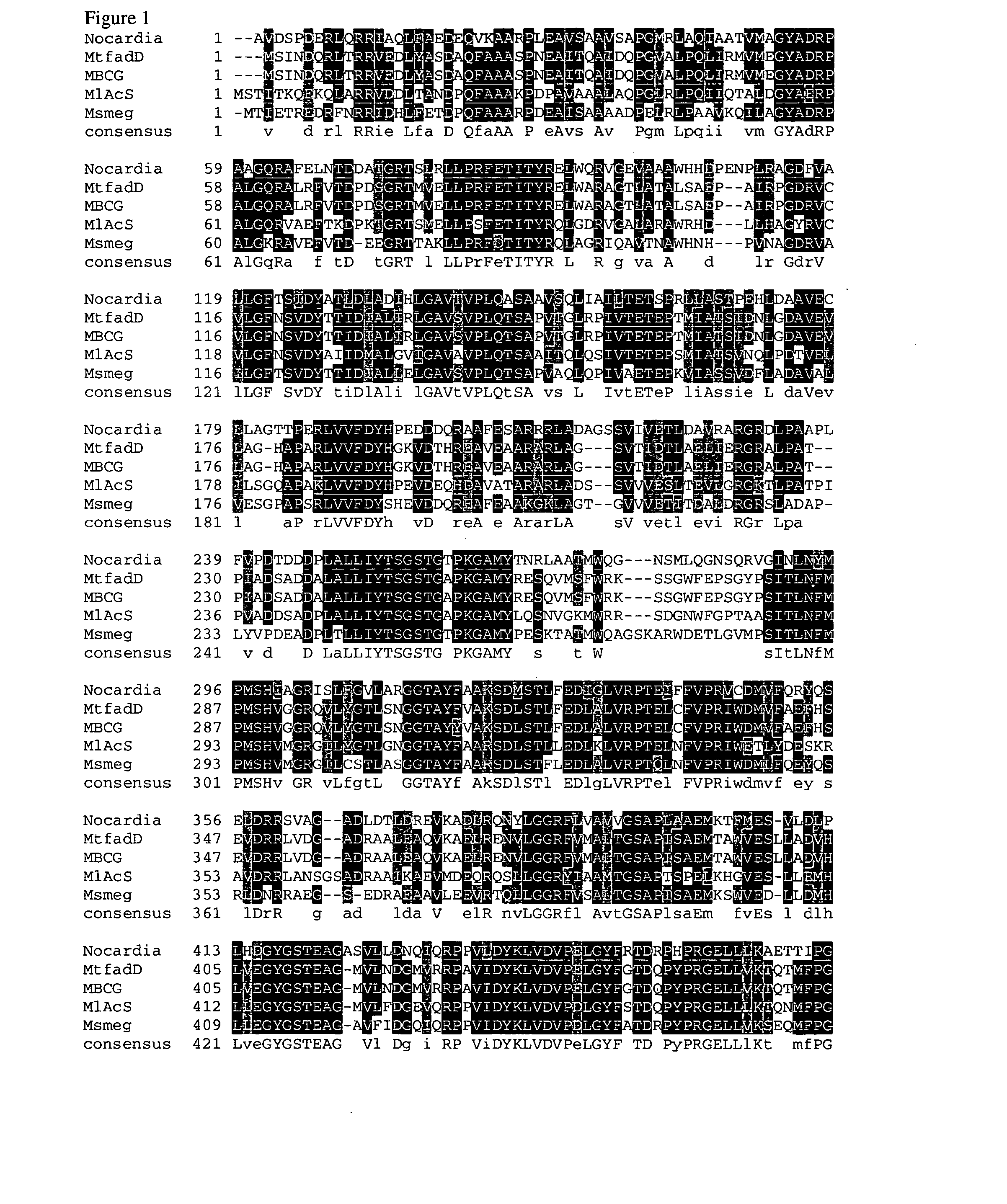

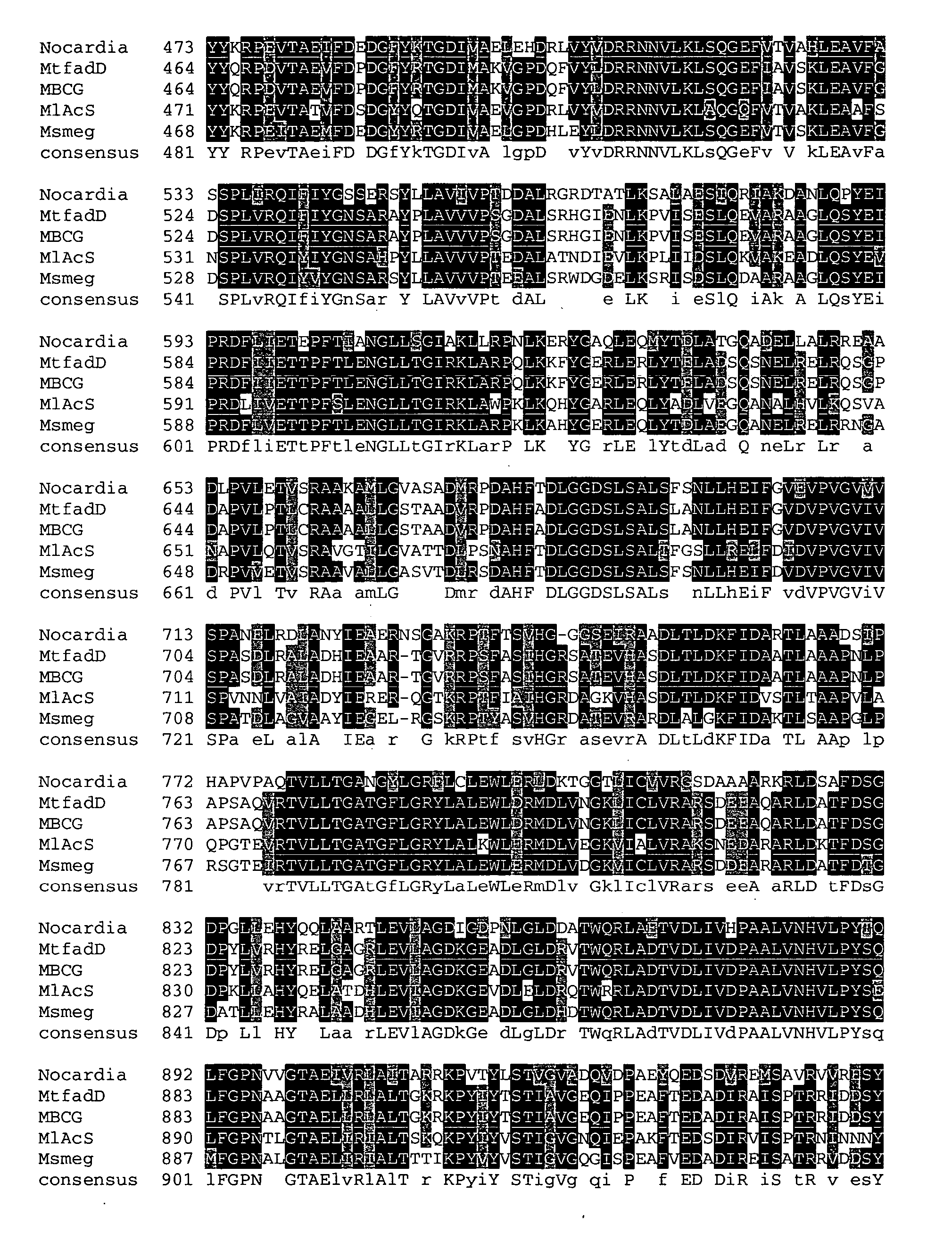

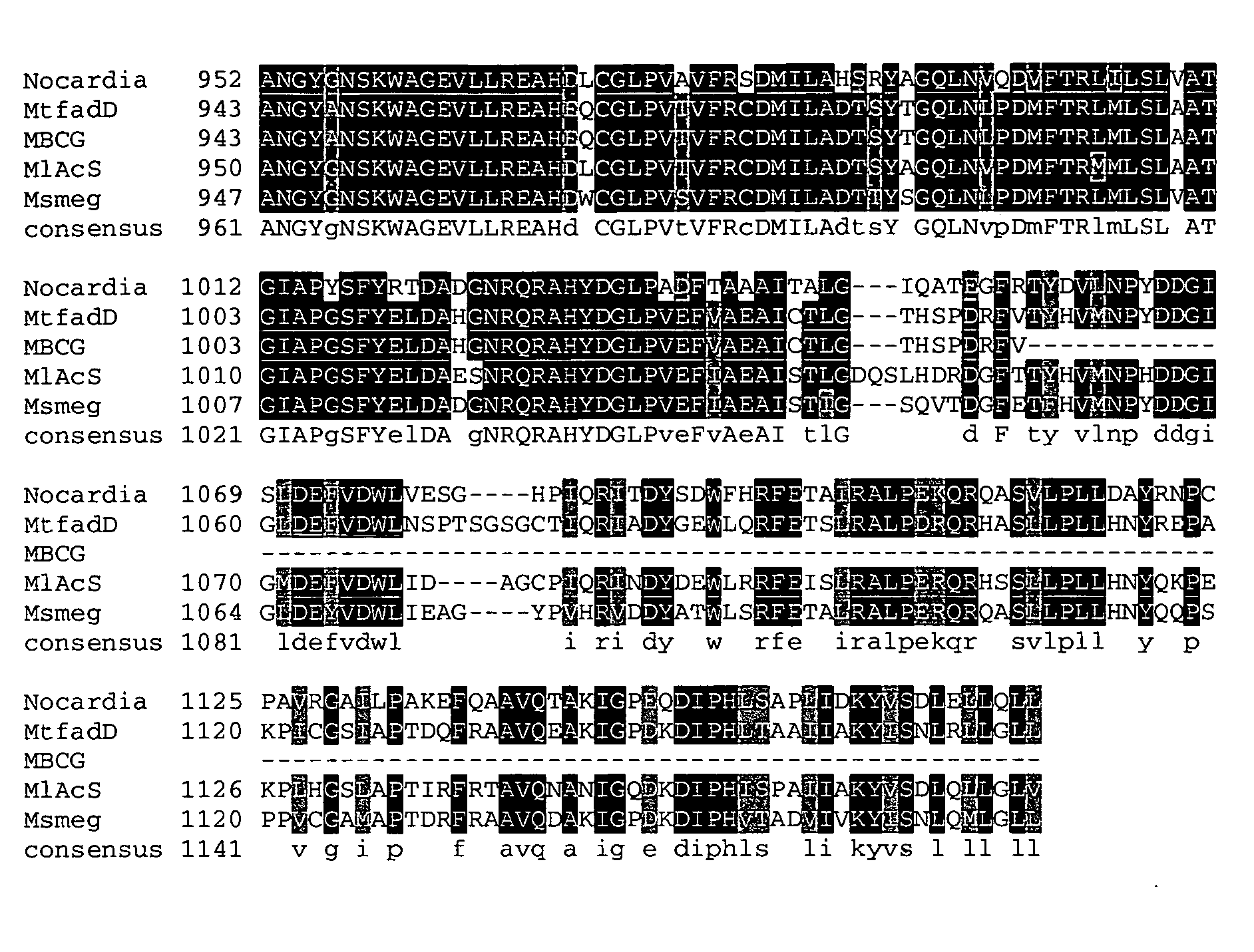

Carboxylic acid reductase polypeptide, nucleotide sequence encoding same and methods of use

The invention provides the nucleotide sequence and amino acid sequence for the enzyme carboxylic acid reductase isolated from bacteria. Expression cassettes, vectors, transformed cells, and variants are also provided as methods for use of recombinant biocatalytic reagents in production of synthetic, aromatic, aliphatic and alicyclic aldehydes and alcohols.

Owner:UNIV OF IOWA RES FOUND

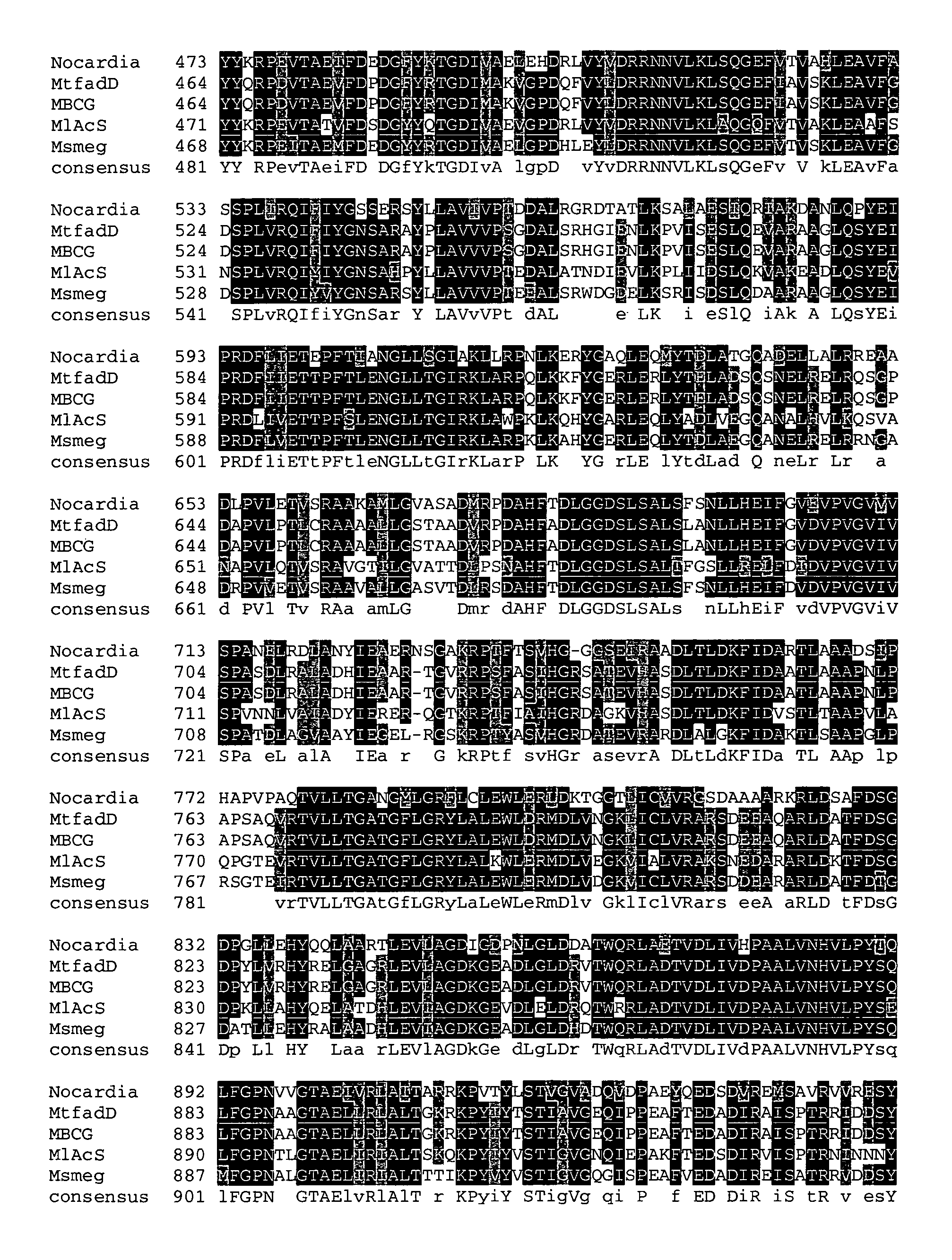

Organisms for the production of cyclohexanone

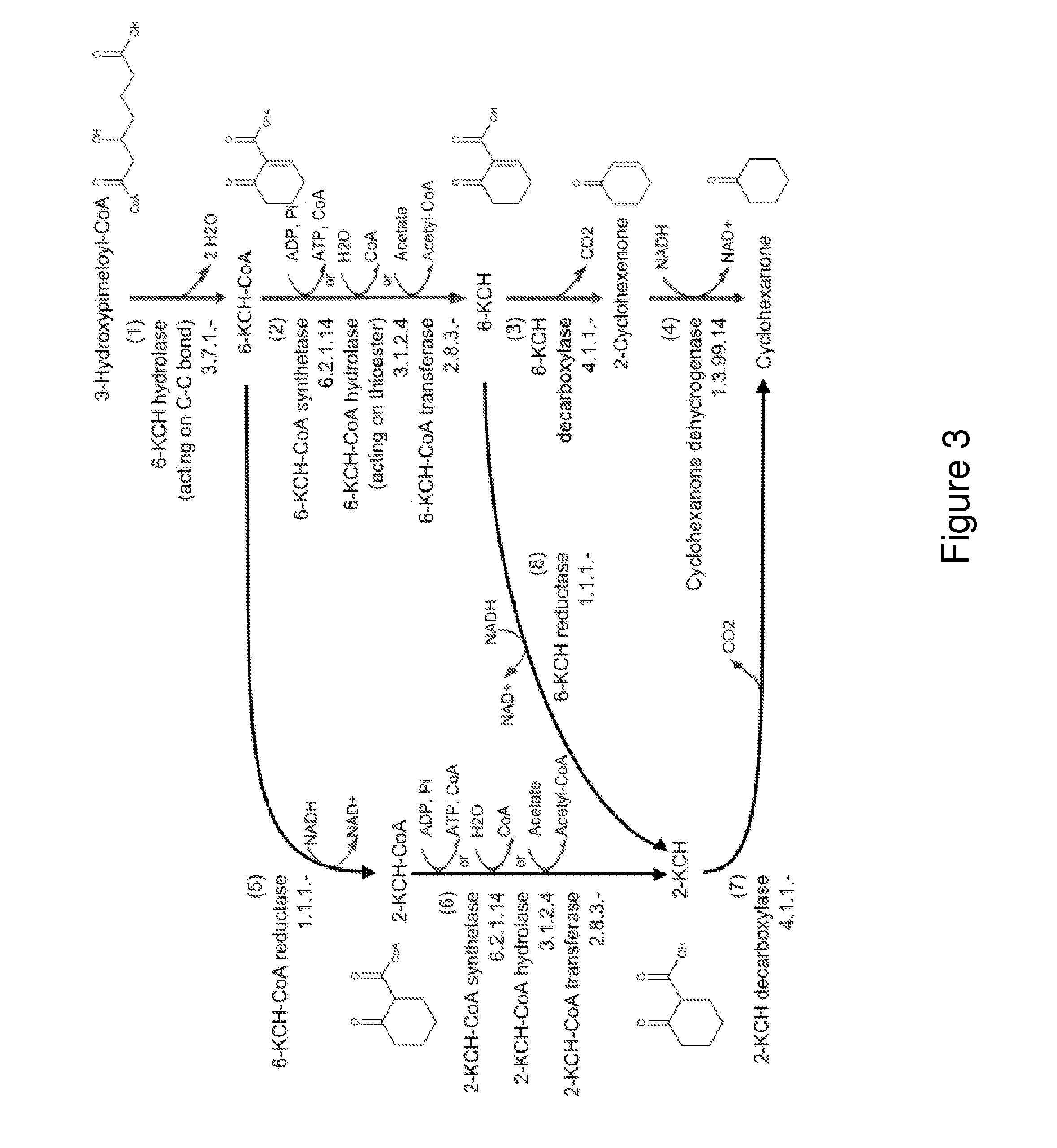

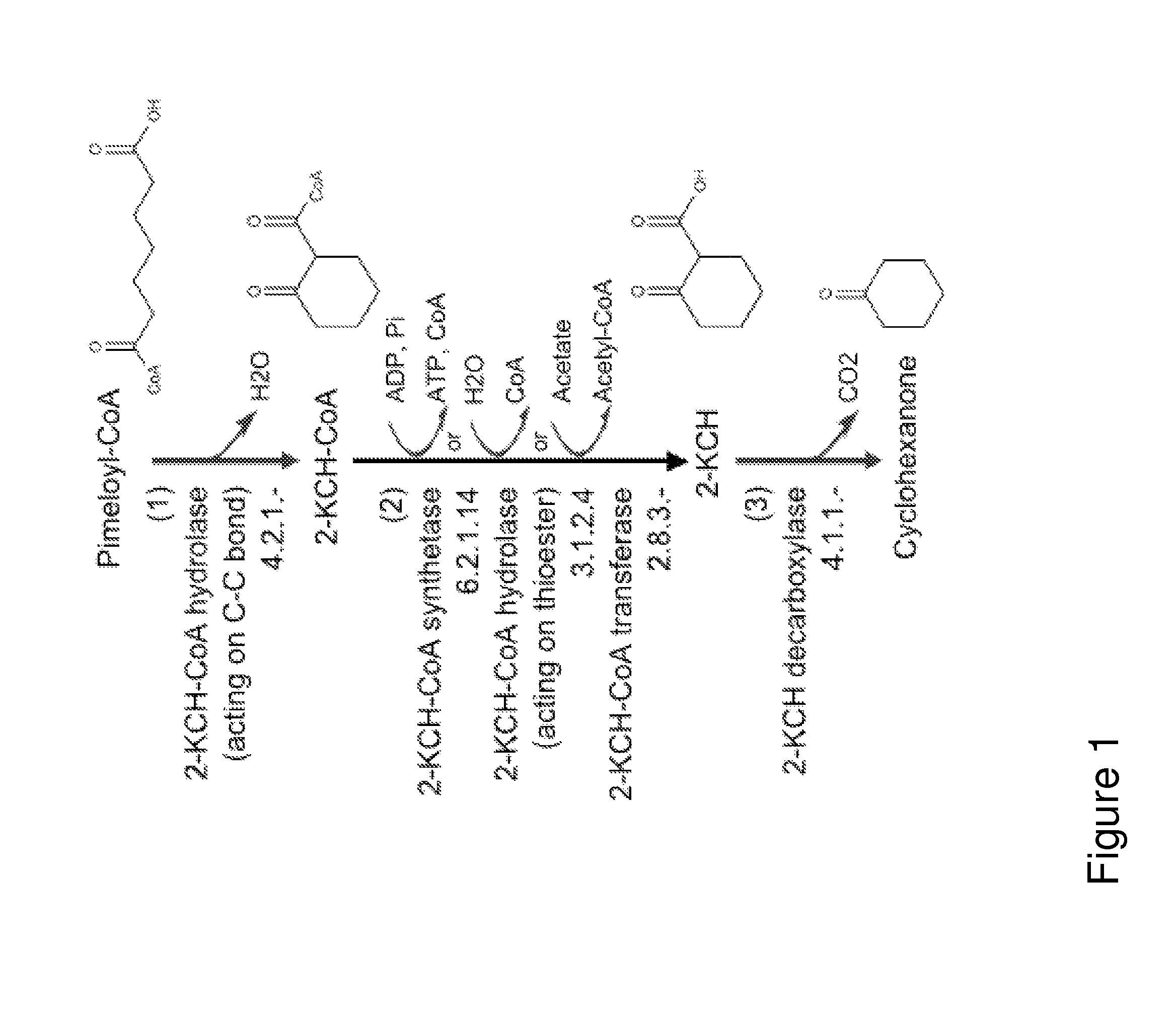

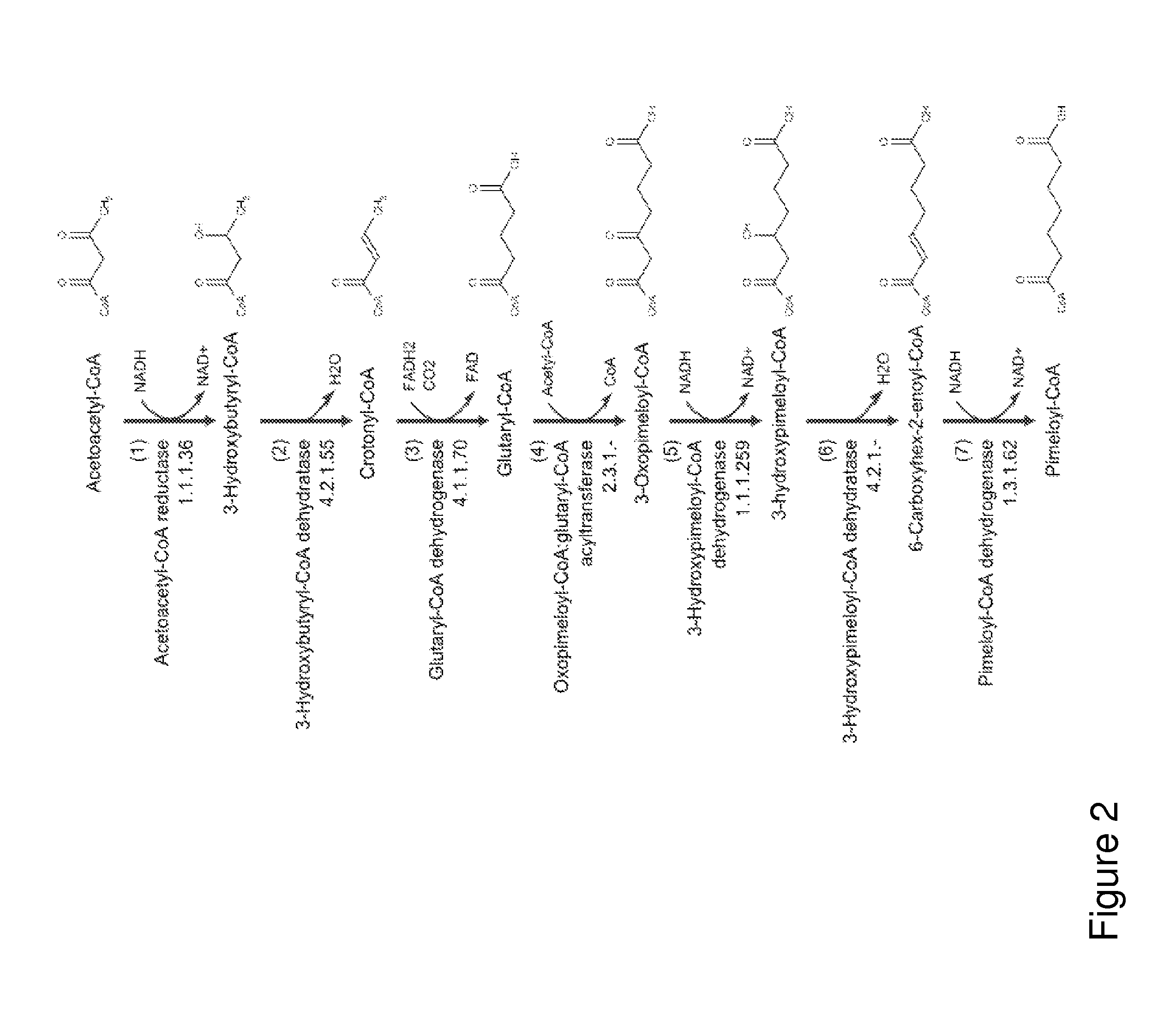

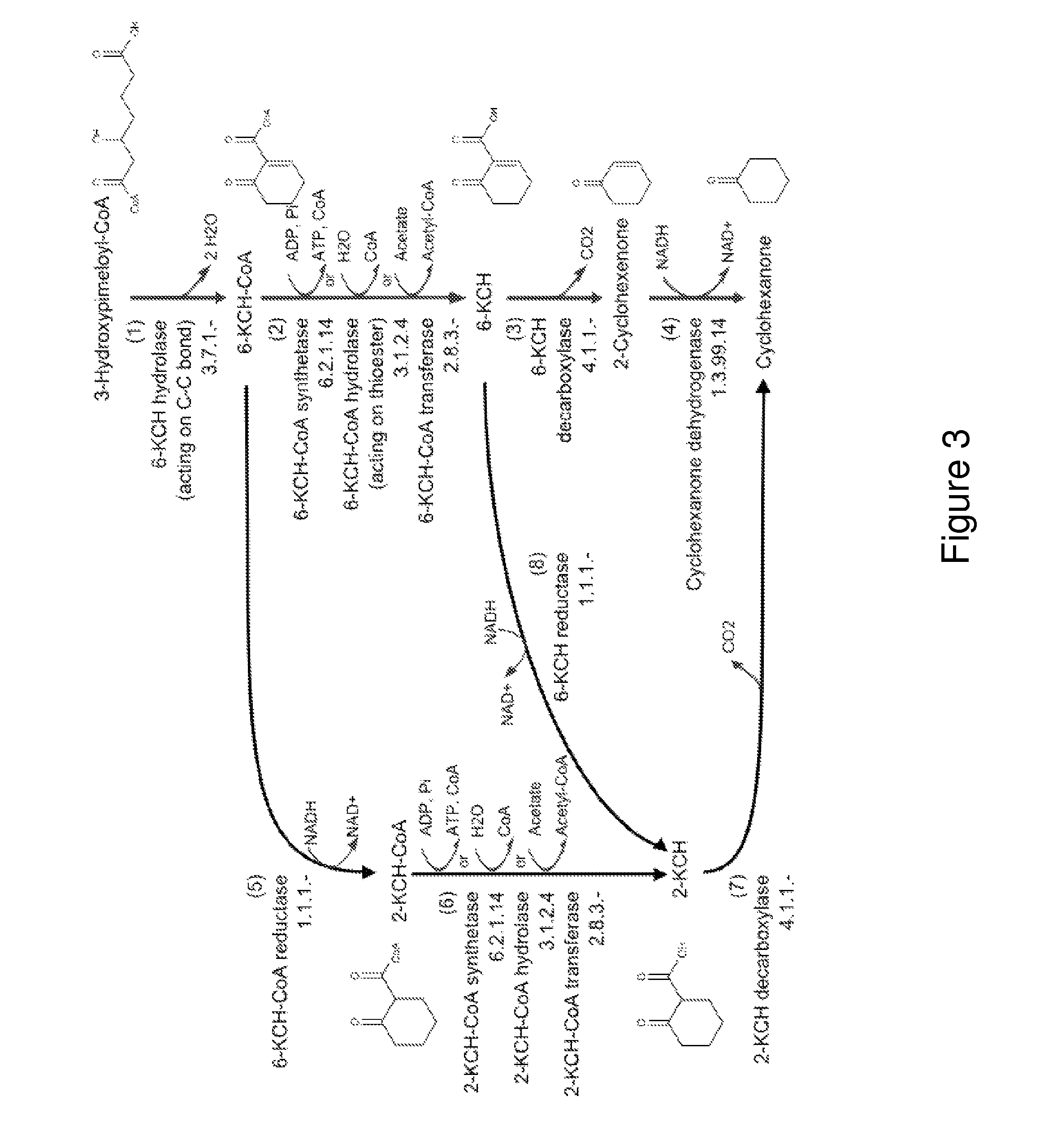

A non-naturally occurring microbial organism has cyclohexanone pathways that include at least one exogenous nucleic acid encoding a cyclohexanone pathway enzyme. A pathway includes a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on C—C bond), a 2-ketocyclohexane-1-carboxylate decarboxylase and an enzyme selected from a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on thioester), a 2-ketocyclohexane-1-carboxyl-CoA transferase, and a 2-ketocyclohexane-1-carboxyl-CoA synthetase. A pathway includes an enzyme selected from a 6-ketocyclohex-1-ene-1-carboxyl-CoA hydrolase (acting on C—C bond), a 6-ketocyclohex-1-ene-1-carboxyl-CoA synthetase, a 6-ketocyclohex-1-ene-1-carboxyl-CoA hydrolase (acting on thioester), a 6-ketocyclohex-1-ene-1-carboxyl-CoA transferase, a 6-ketocyclohex-1-ene-1-carboxyl-CoA reductase, a 6-ketocyclohex-1-ene-1-carboxylate decarboxylase, a 6-ketocyclohex-1-ene-1-carboxylate reductase, a 2-ketocyclohexane-1-carboxyl-CoA synthetase, a 2-ketocyclohexane-1-carboxyl-CoA transferase, a 2-ketocyclohexane-1-carboxyl-CoA hydrolase (acting on thioester), a 2-ketocyclohexane-1-carboxylate decarboxylase, and a cyclohexanone dehydrogenase. A pathway includes an adipate semialdehyde dehydratase, a cyclohexane-1,2-diol dehydrogenase, and a cyclohexane-1,2-diol dehydratase. A pathway includes a 3-oxopimelate decarboxylase, a 4-acetylbutyrate dehydratase, a 3-hydroxycyclohexanone dehydrogenase, a 2-cyclohexenone hydratase, a cyclohexanone dehydrogenase and an enzyme selected from a 3-oxopimeloyl-CoA synthetase, a 3-oxopimeloyl-CoA hydrolase (acting on thioester), and a 3-oxopimeloyl-coA transferase. Each these pathways can include a PEP carboxykinase. A method for producing cyclohexanone includes culturing these non-naturally occurring microbial organisms.

Owner:GENOMATICA INC

Enzymatic Method of Making Aldehydes from Fatty Acids

The present invention provides methods of enzymatically preparing aldehydes from fatty acids by utilizing a carboxylic acid reductase enzyme to reduce the fatty acids to their corresponding aldehydes. The present invention also provides aldehydes prepared by the methods of the invention.

Owner:ARCHER DANIELS MIDLAND CO

Enzymatic method of making aldehydes from fatty acids

ActiveUS7491854B2Organic compound preparationPreparation by hydrogenolysisCarboxylic acid reductaseFatty acid

The present invention provides methods of enzymatically preparing aldehydes from fatty acids by utilizing a carboxylic acid reductase enzyme to reduce the fatty acids to their corresponding aldehydes. The present invention also provides aldehydes prepared by the methods of the invention.

Owner:ARCHER DANIELS MIDLAND CO

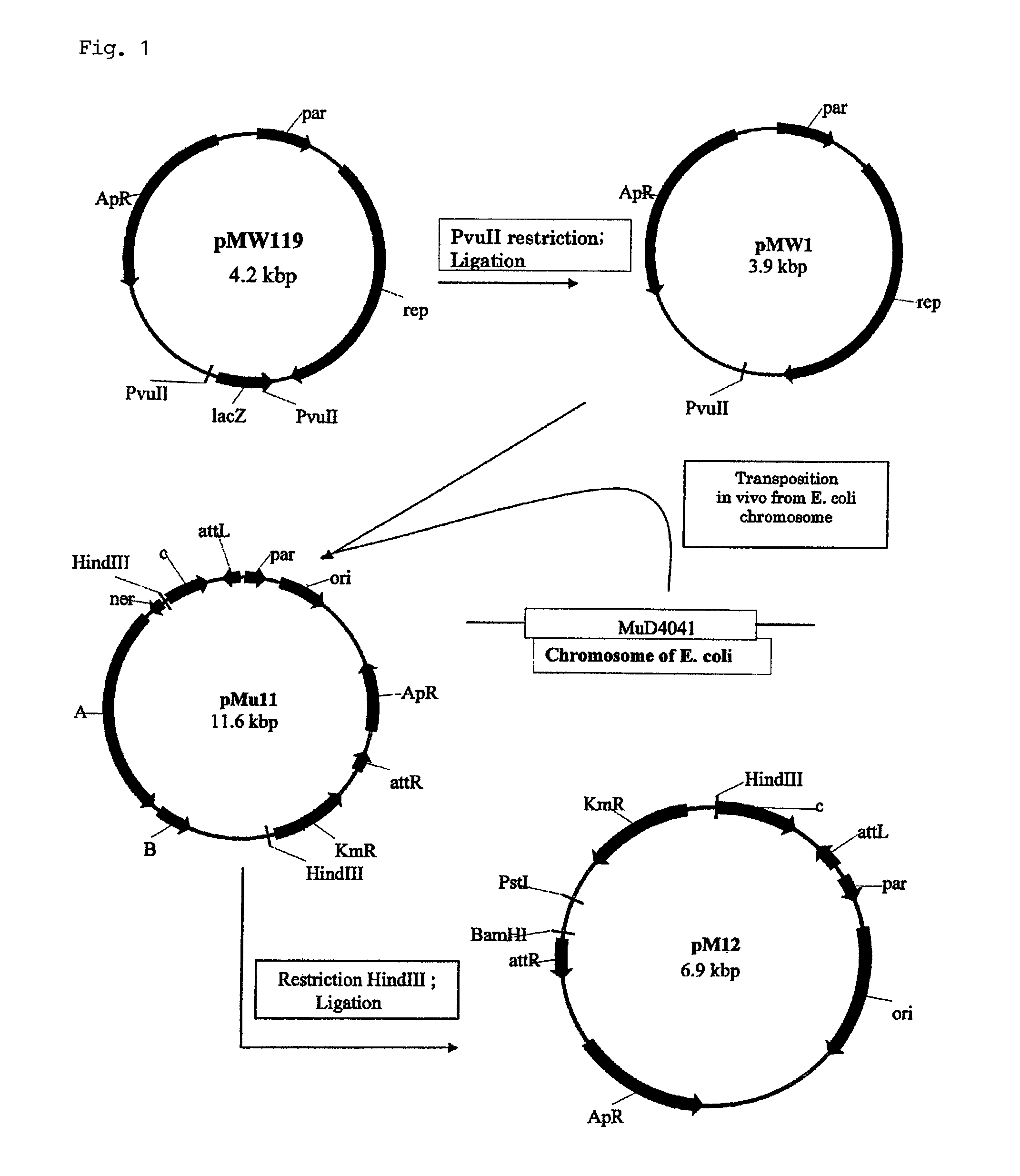

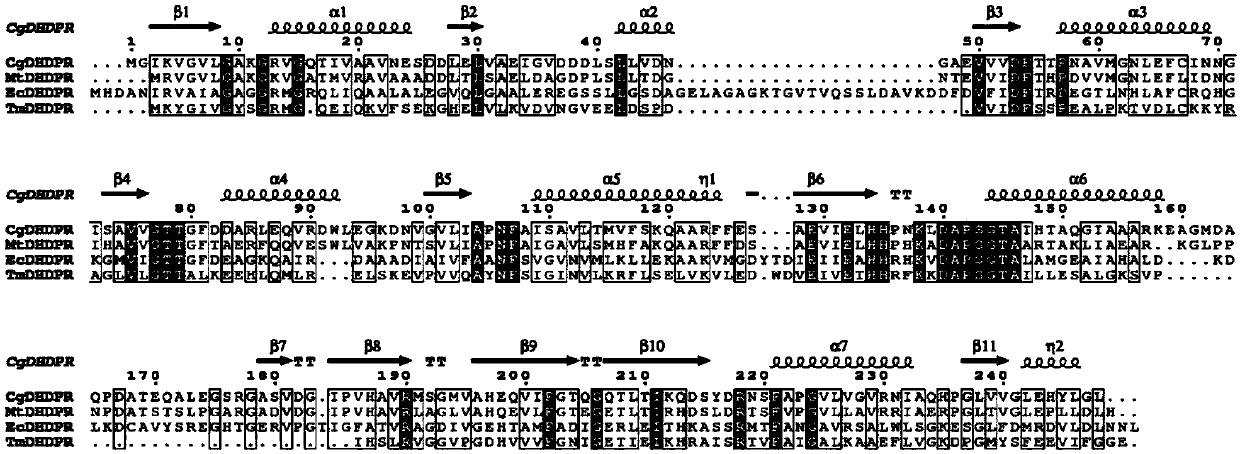

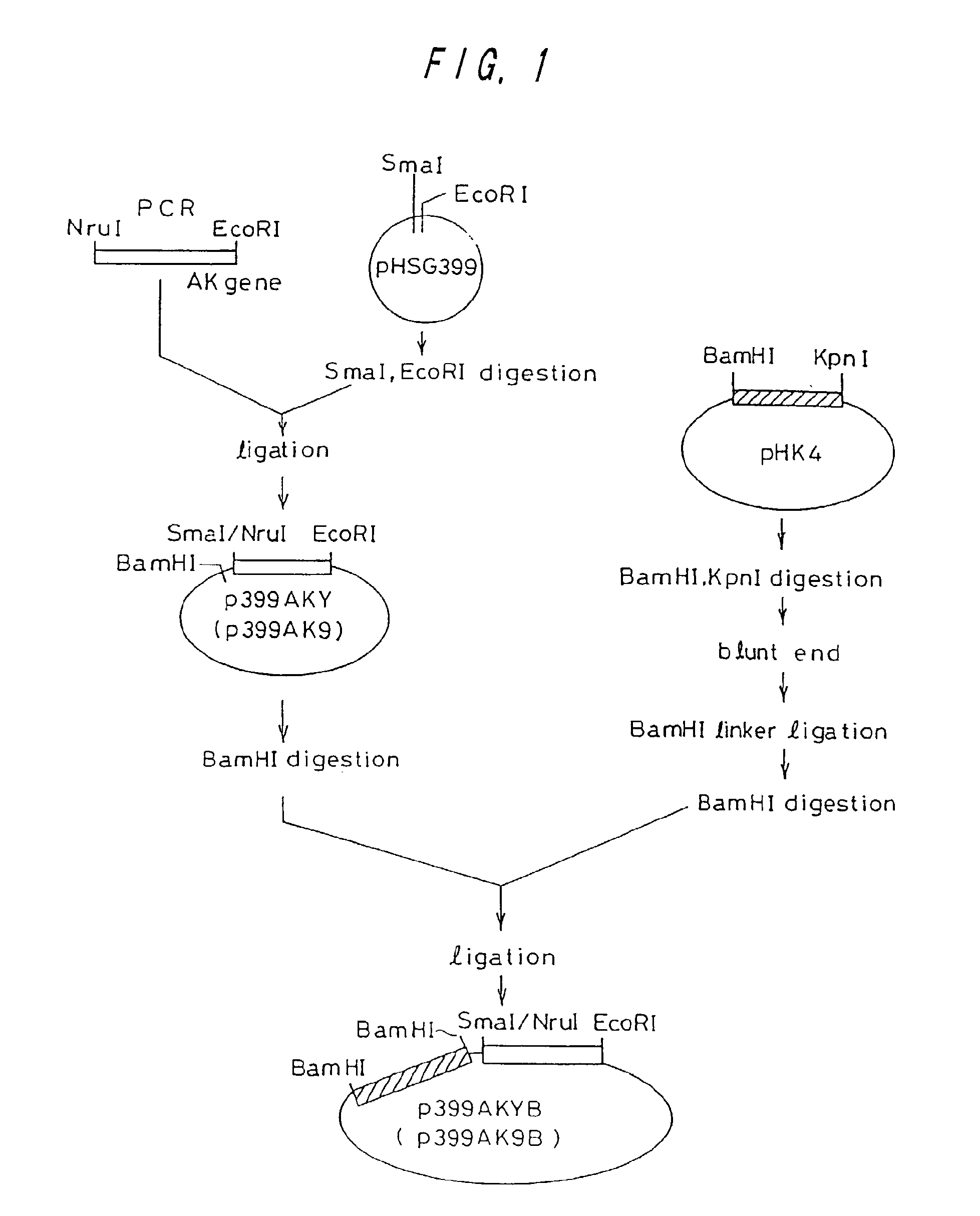

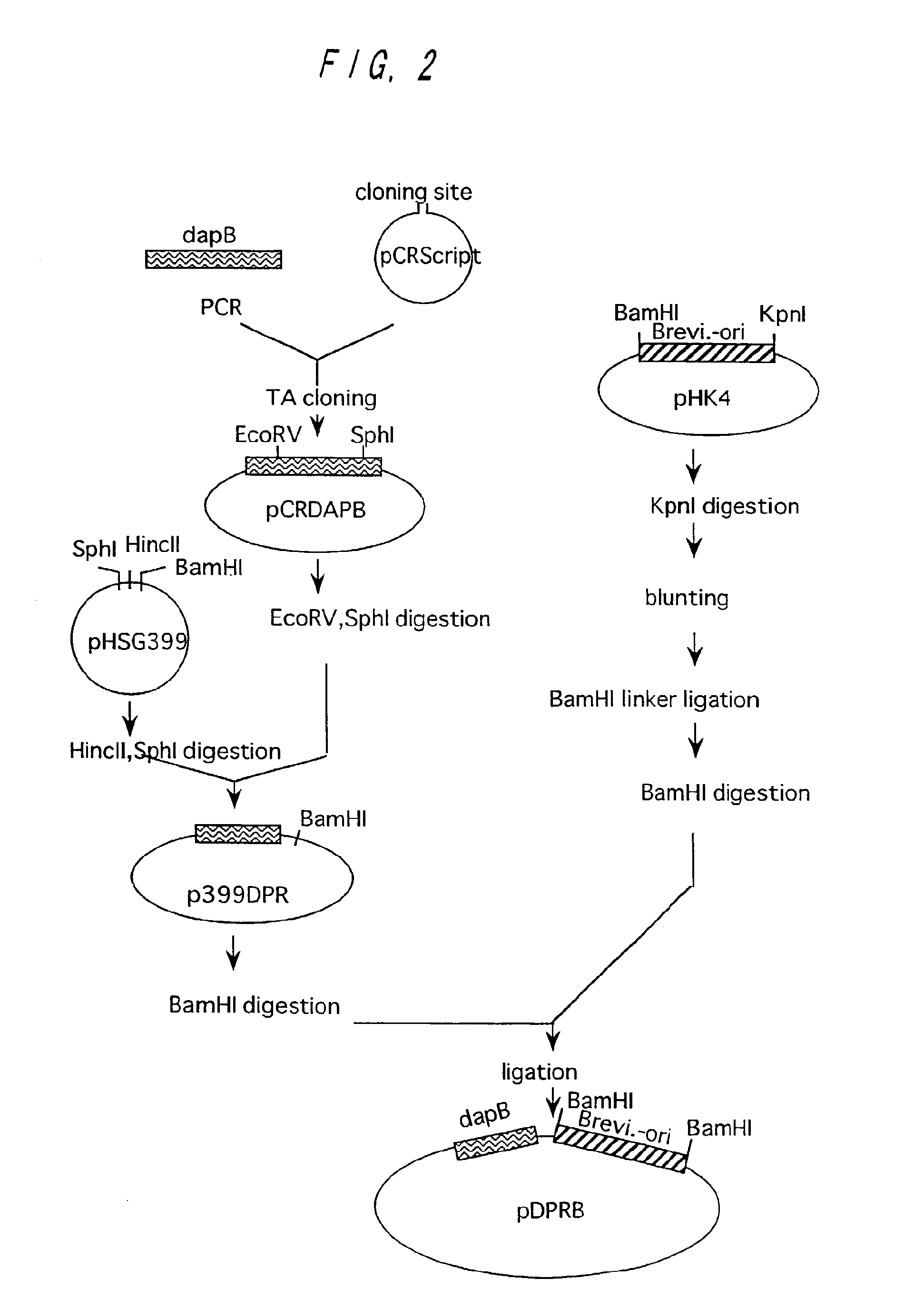

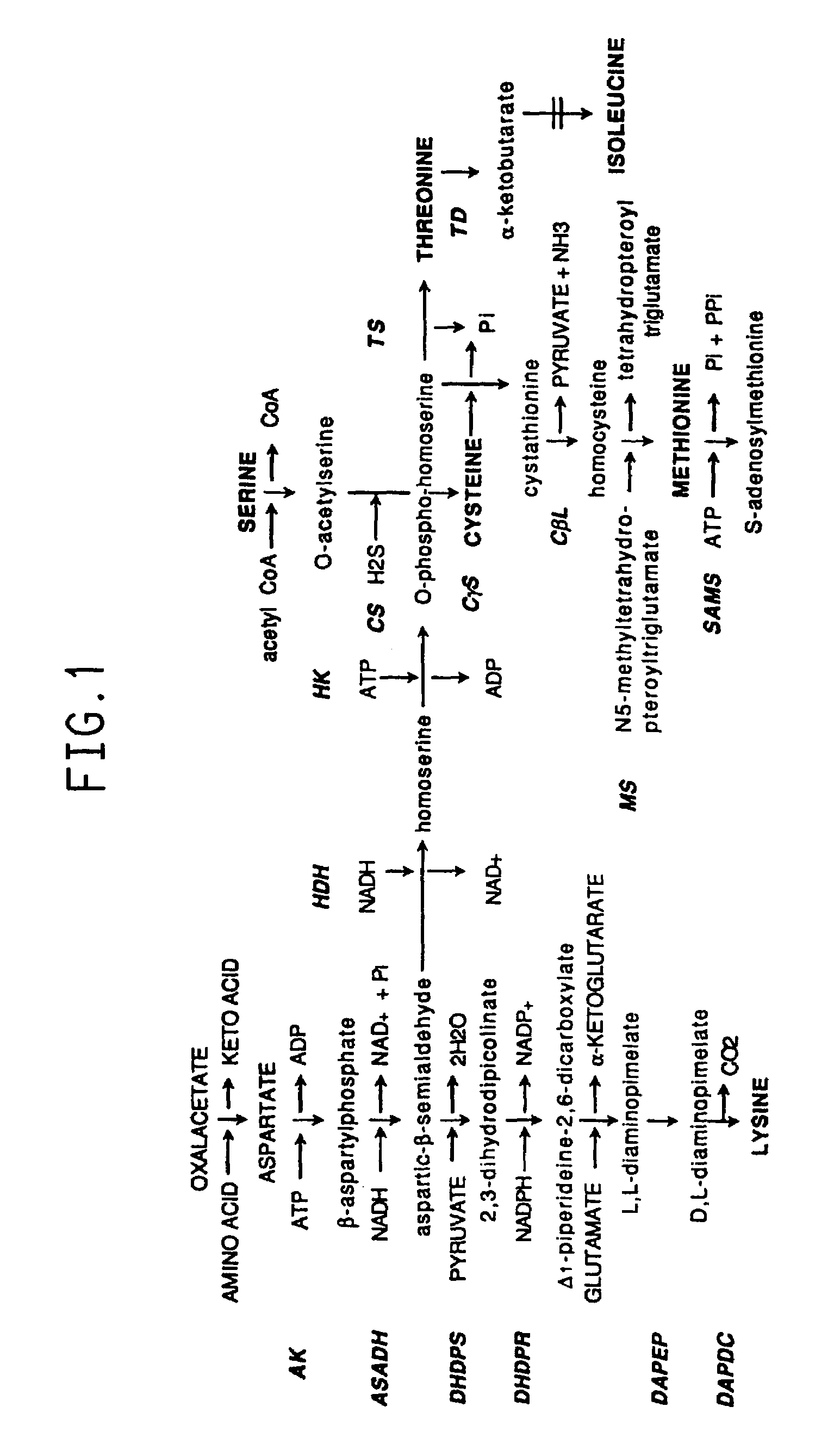

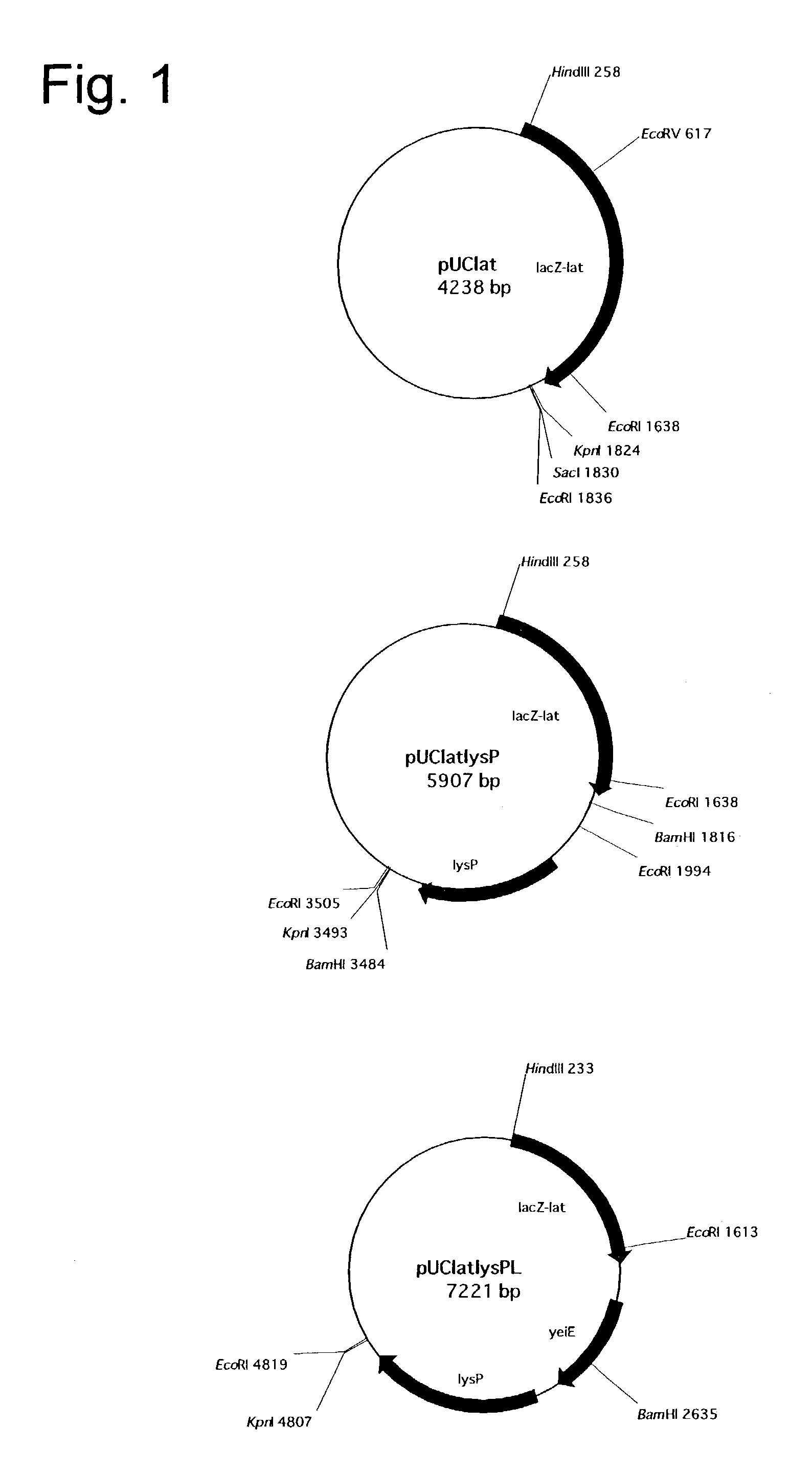

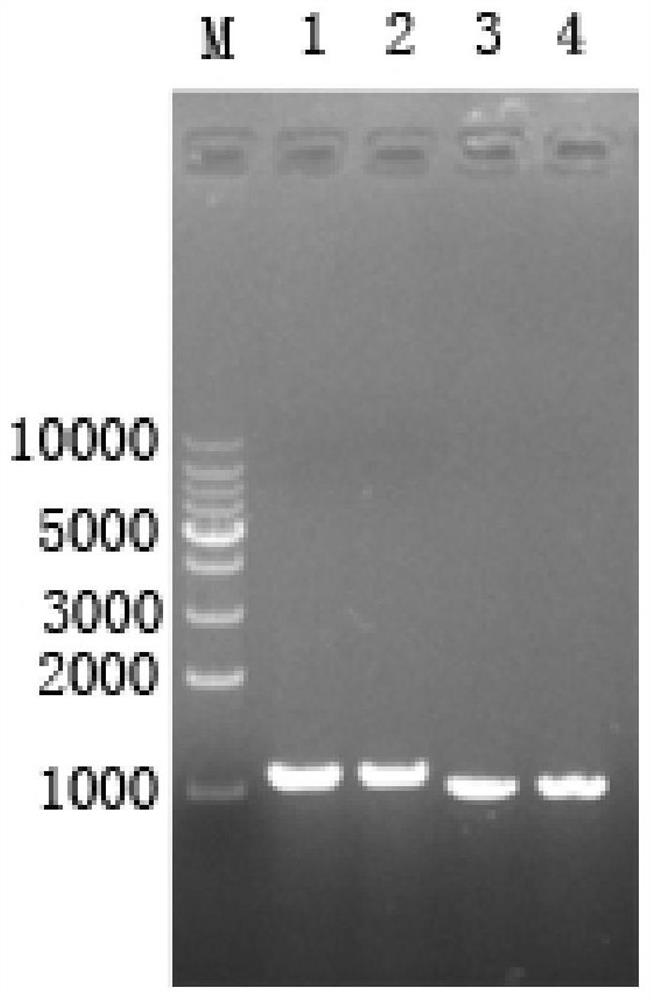

Gene encoding dihydrodipicolinate reductase from Bacillus methanolicus

InactiveUS7211421B2Producing L-lysineNovel methodFungiSugar derivativesEscherichia coliCarboxylic acid reductase

An Escherichia coli mutant strain deficient in dihydrodipicolinate synthase or dihydrodipicolinate reductase is transformed with a chromosomal gene library of Bacillus methanolicus, and a transformant strain which can grow on a minimal medium is selected. Recombinant DNA which codes for dihydrodipicolinate synthase or dihydrodipicolinate reductase (named dapB) is obtained from the transformant.

Owner:AJINOMOTO CO INC

Carboxylic acid reductase polypeptide, nucleotide sequence encoding same and methods of use

The invention provides the nucleotide sequence and amino acid sequence for the enzyme carboxylic acid reductase isolated from bacteria. Expression cassettes, vectors, transformed cells, and variants are also provided as methods for use of recombinant biocatalytic reagents in production of synthetic, aromatic, aliphatic and alicyclic aldehydes and alcohols.

Owner:UNIV OF IOWA RES FOUND

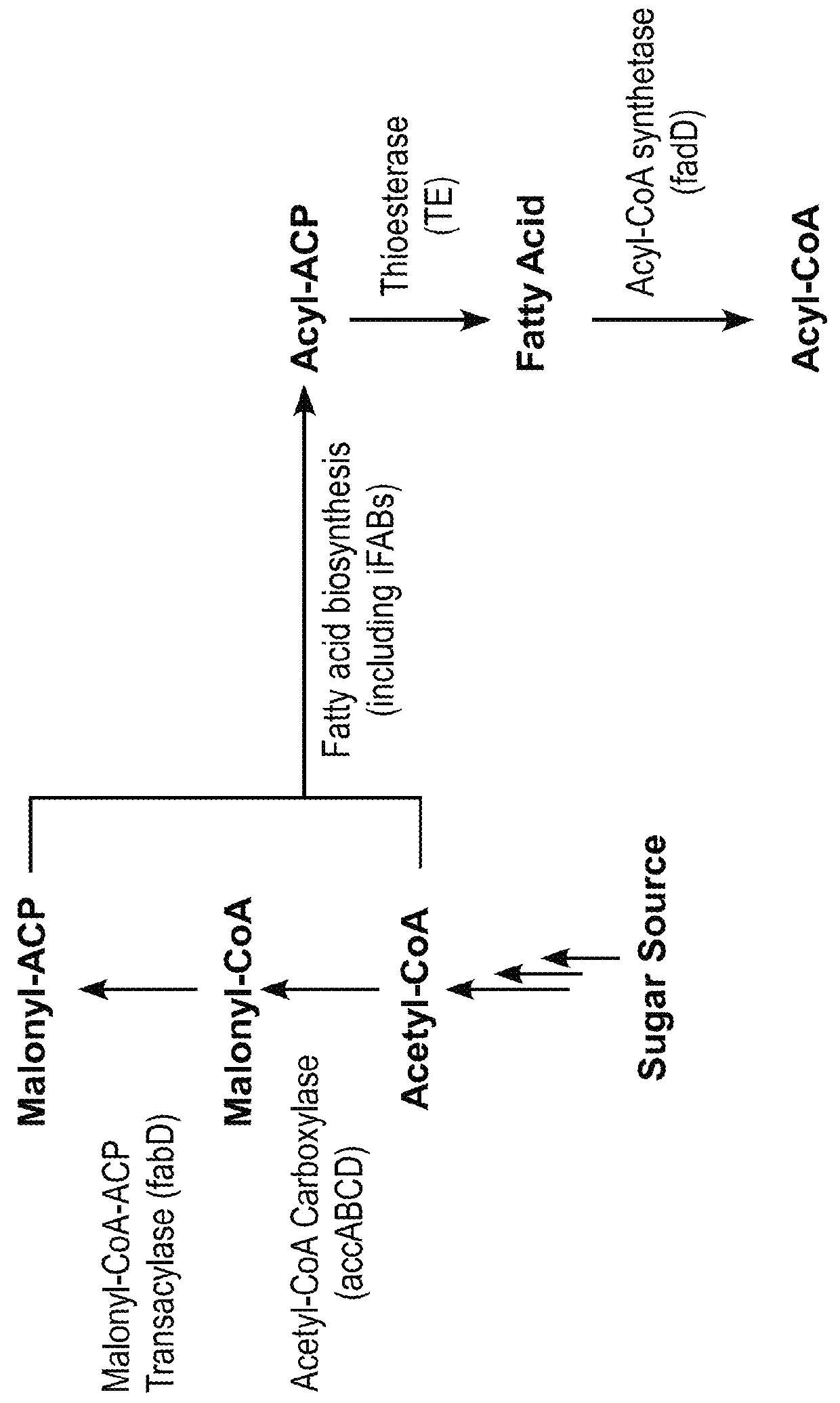

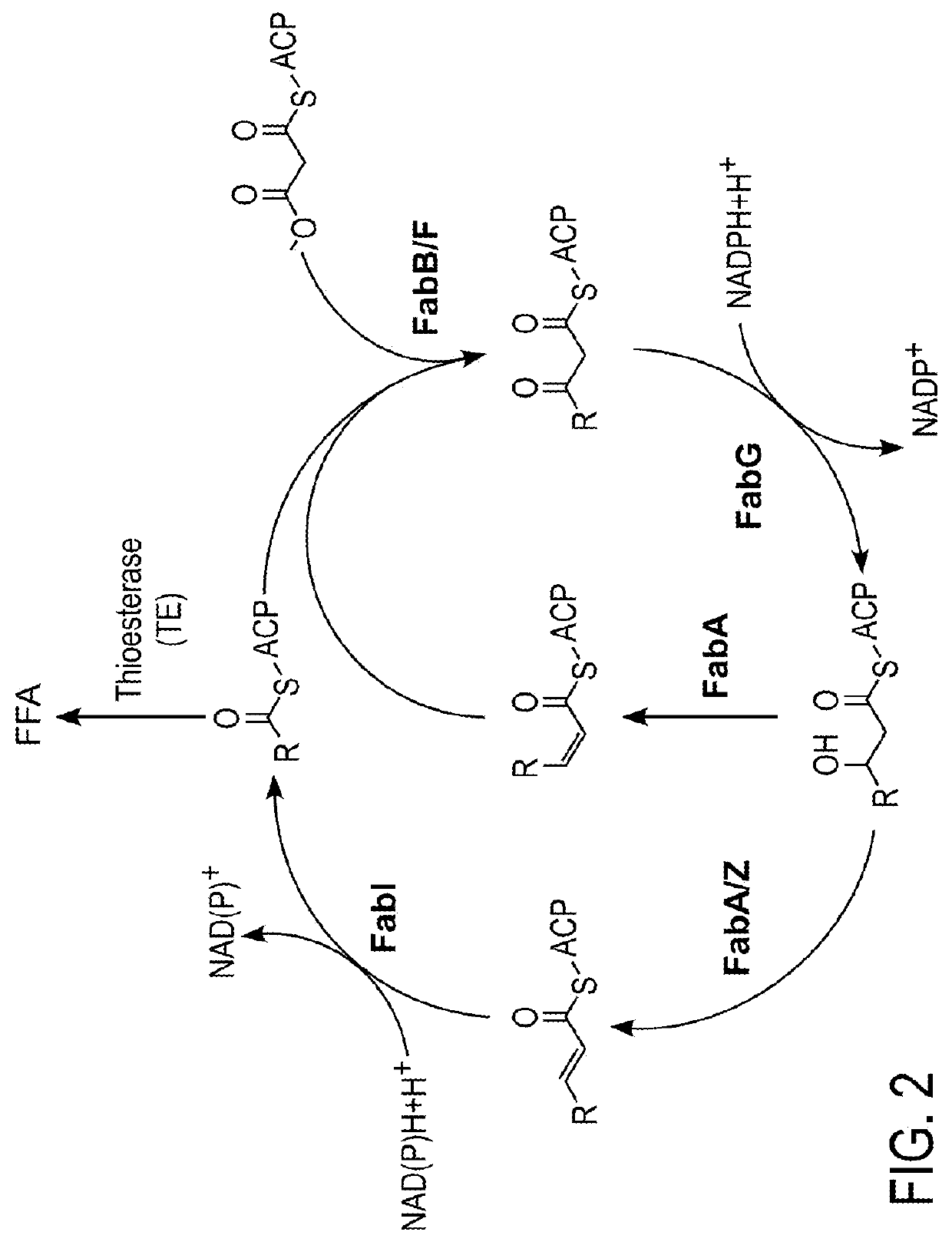

Car enzymes and improved production of fatty alcohols

The disclosure relates to variant carboxylic acid reductase (CAR) enzymes for the improved production of fatty alcohols in recombinant host cells.

Owner:GENOMATICA INC

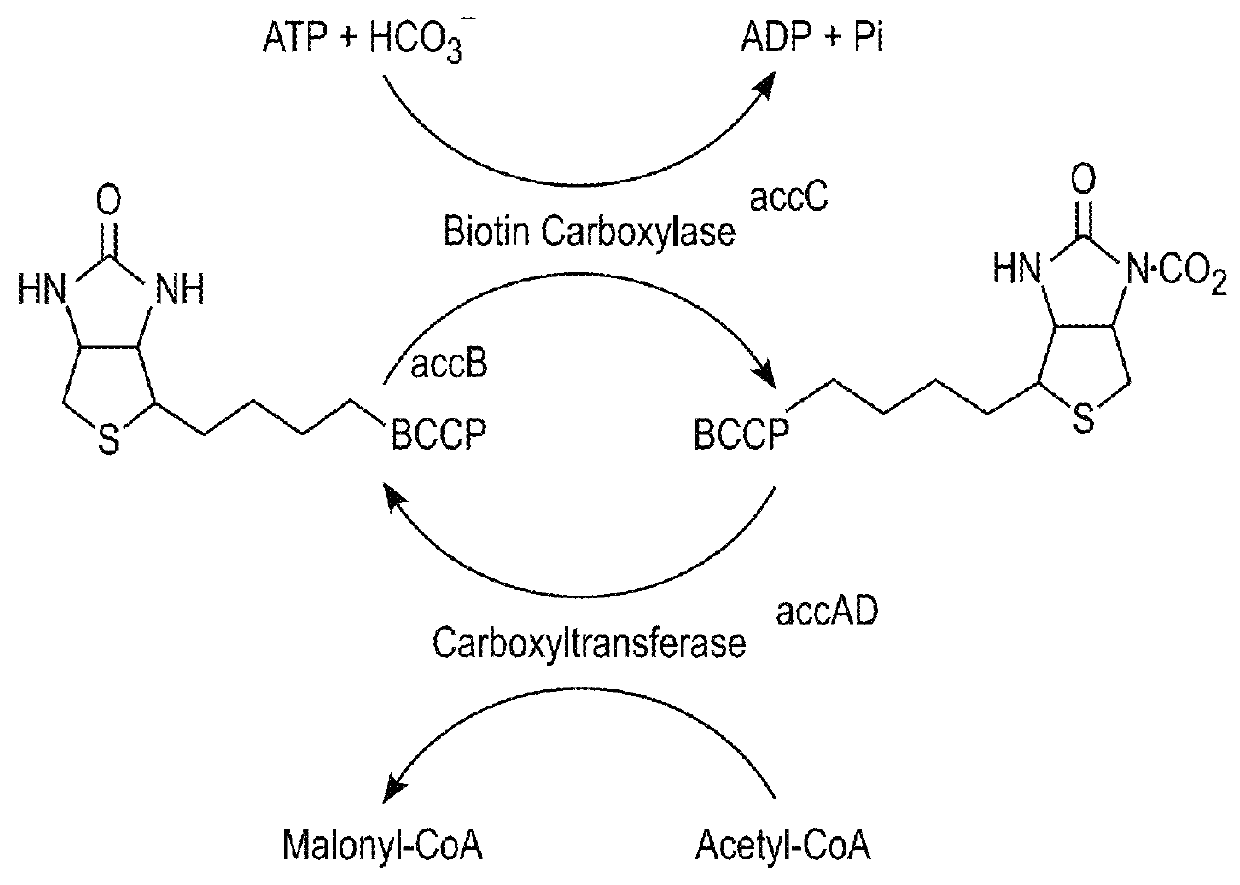

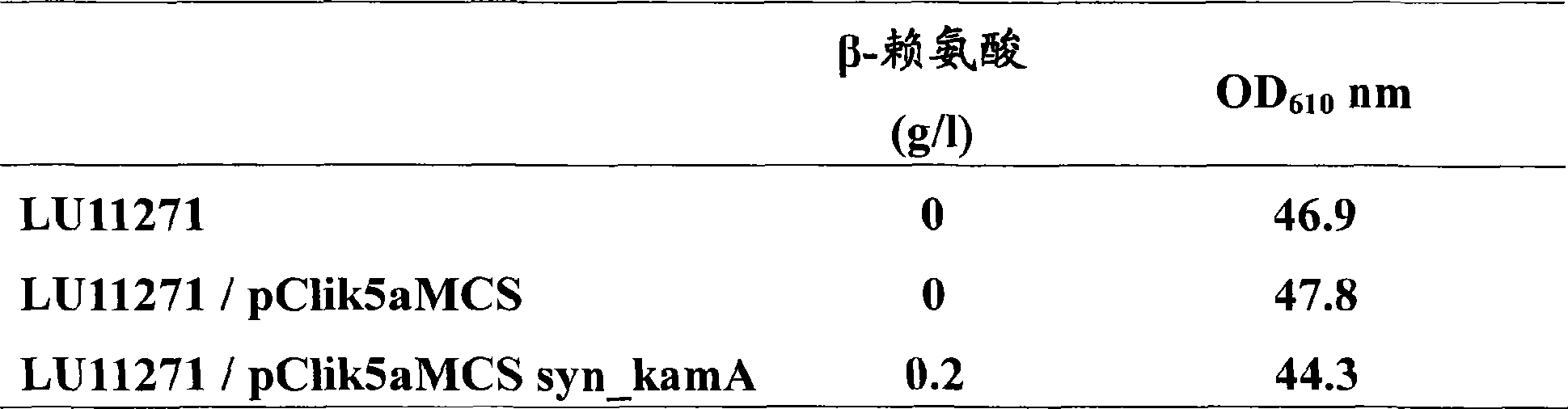

Process for the production of beta-lysine

InactiveCN101400799AFermentationVector-based foreign material introductionPhosphoenolpyruvate carboxylaseTransketolase

Process for the production of -lysine by constructing a recombinant microorganism which has a deregulated lysine 2,3-aminomutase gene and at least one deregulated gene selected from the group (i) which consists of aspartokinase, aspartatesemialdehyde dehydrogenase, dihydrodipicolinate synthase, dihydrodipicolinate reductase, tetrahydrodipicolinate succinylase, succinyl-amino-ketopimelate transaminase, succinyl-diamino-pimelate desuccinylase, diaminopimelate epimerase, diaminopimelate dehydrogenase, arginyl-tRNA synthetase, diaminopimelate decarboxylase, pyruvate carboxylase, phosphoenolpyruvate carboxylase, glucose-6-phosphate dehydrogenase, transketolase, transaldolase, 6-phosphogluconolactonase, fructose 1,6-biphosphatase, homoserine dehydrogenase, phophoenolpyruvate carboxykinase, succinyl-CoA synthetase, methylmalonyl-CoA mutase, provided that if aspartokinase is deregulated as gene (i) at least a second gene (i) other than aspartokinase has to be deregulated, and cultivating said microorganism.

Owner:BASF SE

Process for the production of beta-lysine

InactiveUS20090029425A1FermentationVector-based foreign material introductionPhosphoenolpyruvate carboxylaseTransketolase

Process for the production of -lysine by constructing a recombinant microorganism which has a deregulated lysine 2,3-aminomutase gene and at least one deregulated gene selected from the group (i) which consists of aspartokinase, aspartatesemialdehyde dehydrogenase, dihydrodipicolinate synthase, dihydrodipicolinate reductase, tetrahydrodipicolinate succinylase, succinyl-amino-ketopimelate transaminase, succinyl-diamino-pimelate desuccinylase, diaminopimelate epimerase, diamino-pimelate dehydrogenase, arginyl-tRNA synthetase, diaminopimelate decarboxylase, pyruvate carboxylase, phosphoenolpyruvate carboxylase, glucose-6-phosphate dehydrogenase, transketolase, transaldolase, 6-phosphogluconolactonase, fructose 1,6-biphosphatase, homoserine dehydrogenase, phophoenolpyruvate carboxykinase, succinyl-CoA synthetase, methylmalonyl-CoA mutase, provided that if aspartokinase is deregulated as gene (i) at least a second gene (i) other than aspartokinase has to be deregulated, and cultivating said microorganism.

Owner:BASF AG

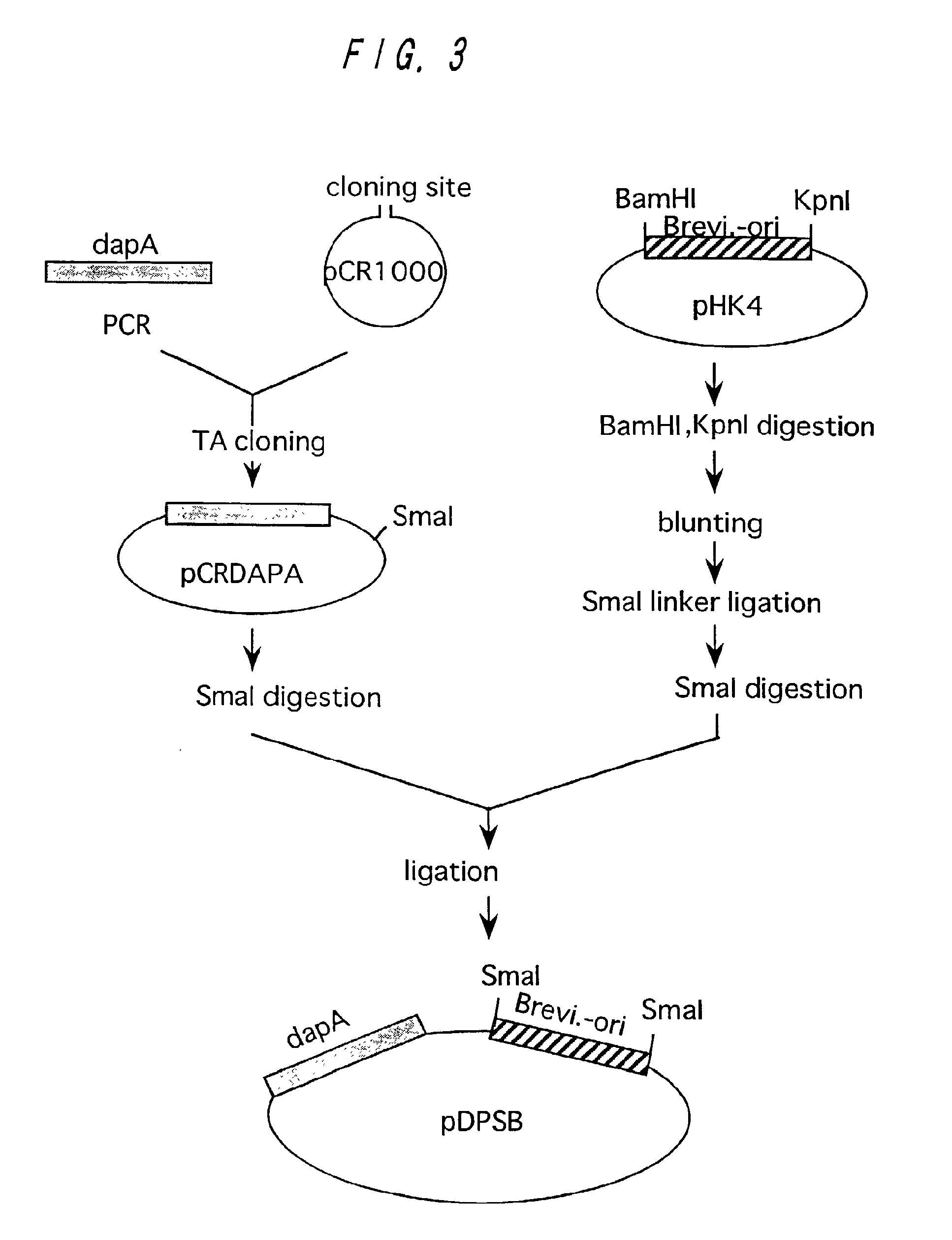

Lysine biosynthetic system genes derived from thermophilic bacteria

InactiveUS20050233416A1Improve heat resistanceProducing L-lysineFungiSugar derivativesEscherichia coliCarboxylic acid reductase

An Escherichia coli mutant strain deficient in dihydrodipicolinate synthase or dihydrodipicolinate reductase is transformed with a chromosomal gene library of Bacillus methanolicus, and a transformant strain which can grow on a minimal medium is selected. Recombinant DNA which codes for dihydrodipicolinate synthase or dihydrodipicolinate reductase is obtained from the transformant.

Owner:AJINOMOTO CO INC

Method for production of L-lysine using methanol-utilizing bacterium

InactiveUS8017363B2Efficient productionAbundantly and inexpensively availableBacteriaOxidoreductasesBacteroidesDiaminopimelate dehydrogenase

A method for production of L-lysine is provided which includes the steps of cultivating a methanol-utilizing bacterium in a culture medium to produce and accumulate L-lysine in the culture medium and collecting the L-lysine from the culture medium, wherein the methanol-utilizing bacterium contains DNA encoding dihydrodipicolinate synthetase which is desensitized to feedback inhibition by L-lysine and DNA encoding a LysE protein that can enhance the excretion of L-lysine out of the methanol-utilizing bacterium, and the bacterium is modified so as to increase the intracellular activities of diaminopimelic acid dehydrogenase, diaminopimelic acid decarboxylase, dihydrodipicolinic acid reductase and aspartate-semialdehyde dehydrogenase.

Owner:AJINOMOTO CO INC

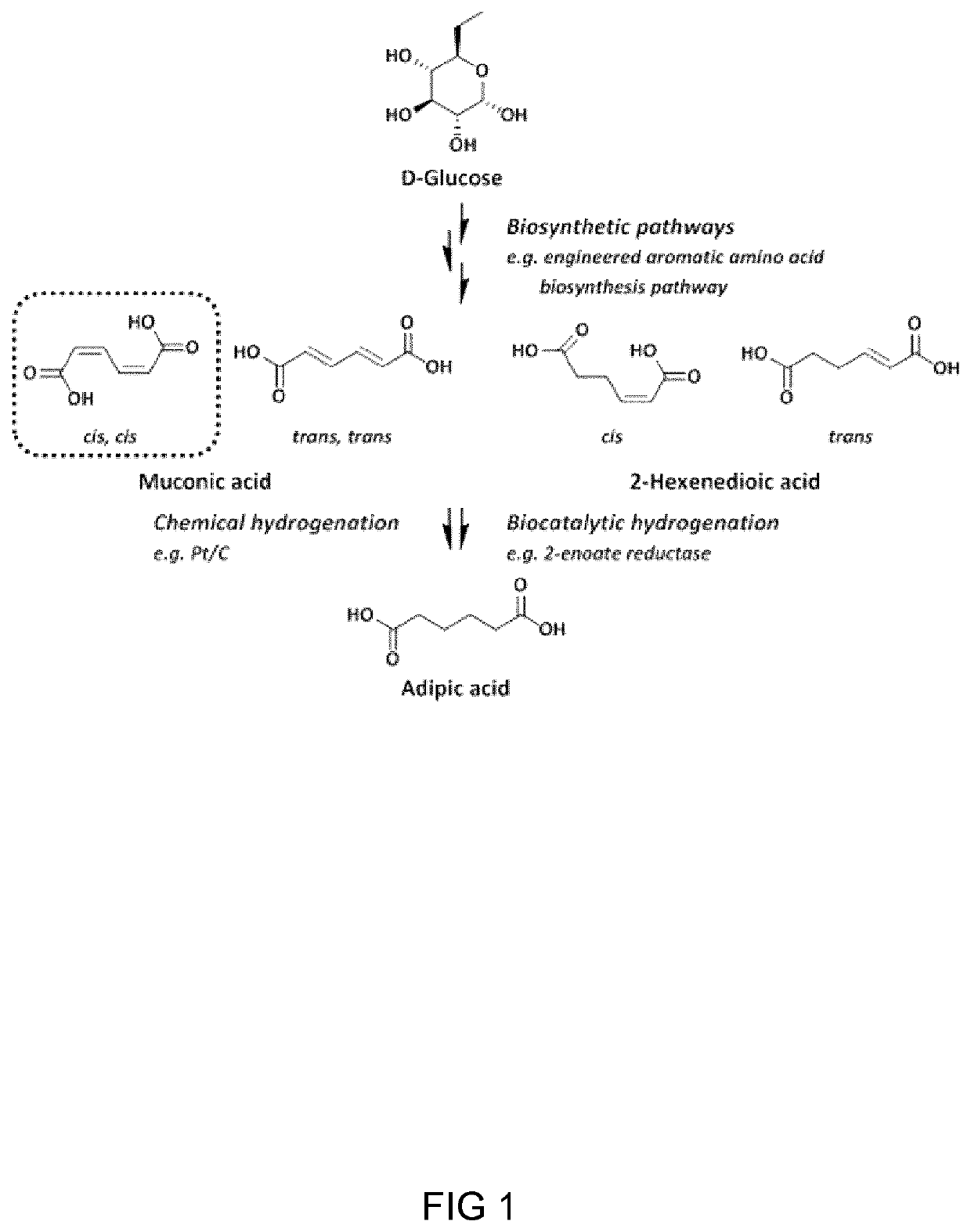

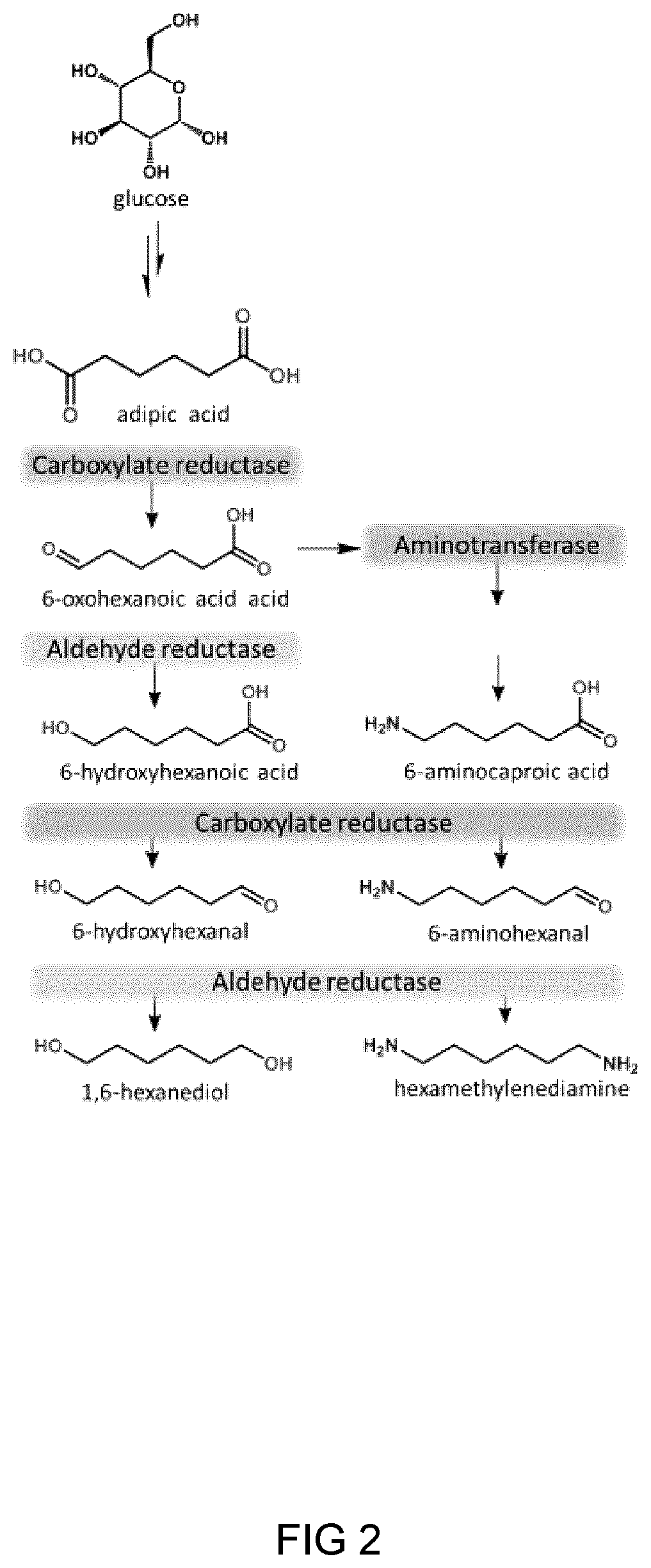

Process And Microorganism For Synthesis Of Adipic Acid From Carboxylic Acids

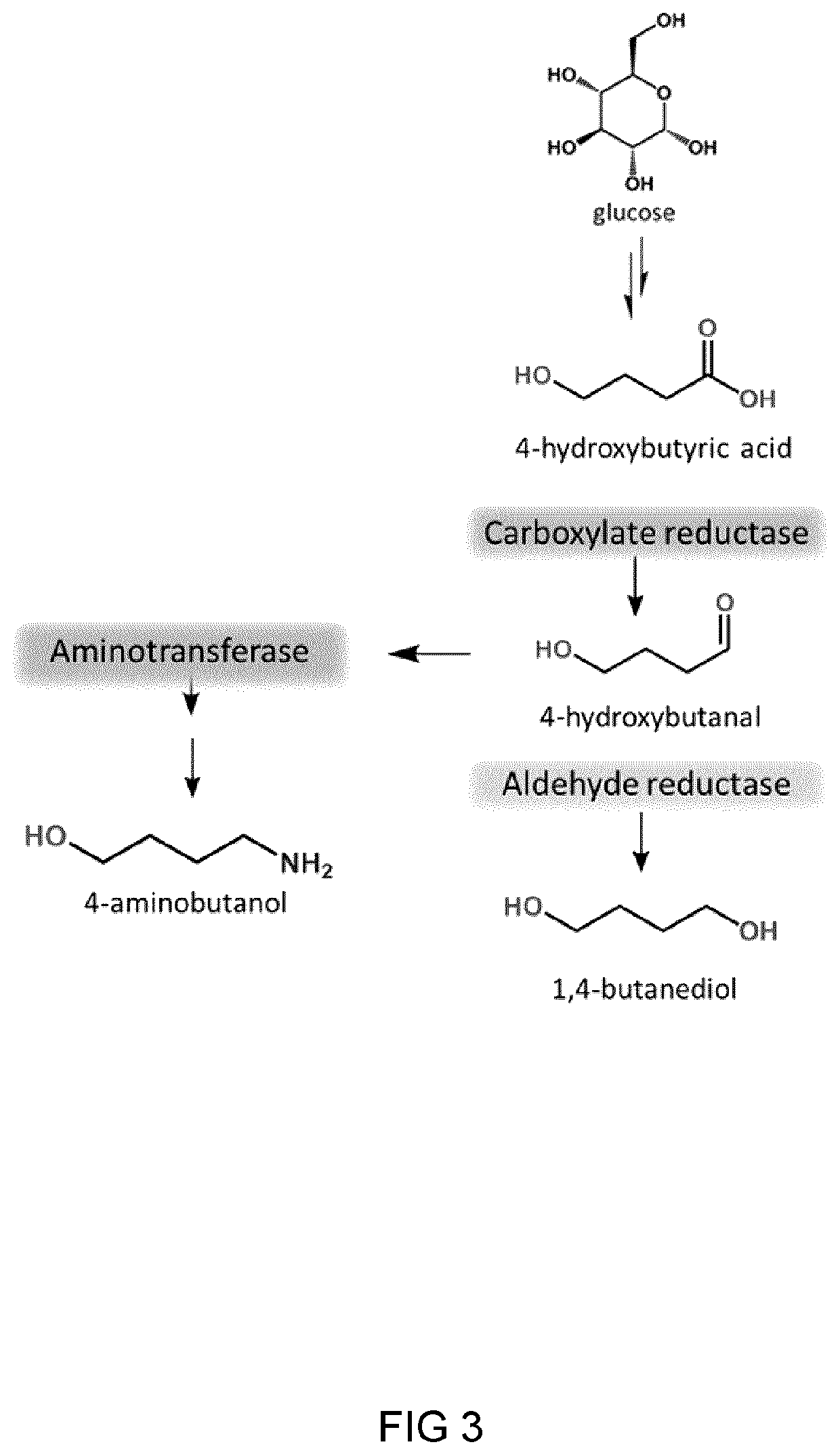

A method for biosynthesis of polymer precursors, including, adipic acid, 1,6-hexanediol, 6-hydroxyhexanoic and 6-aminocaproic acids from carboxylic acids is provided. A method for biosynthesis of adipic acid from six-carbon dicarboxylic acids having α, β-enoate reductase activity by treatment with an enzyme is provided. The biocatalytic conversion of aliphatic and hydroxycarboxylic acids to corresponding aldehydes, alcohols, and amines using novel carboxylate reductases, aldehyde reductases, and aminotransferases is described. Also provided are genetically engineered microorganisms for use in the biosynthetic processes.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

Organisms for the production of cyclohexanone

Owner:GENOMATICA INC

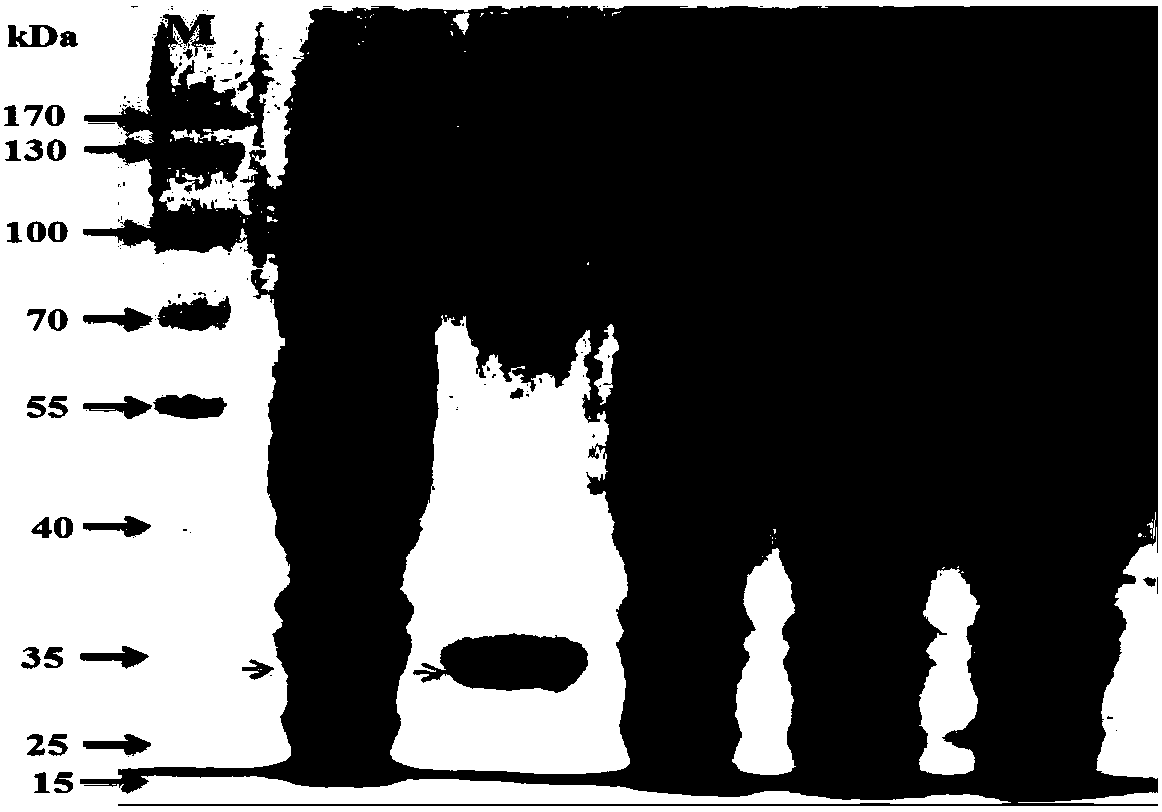

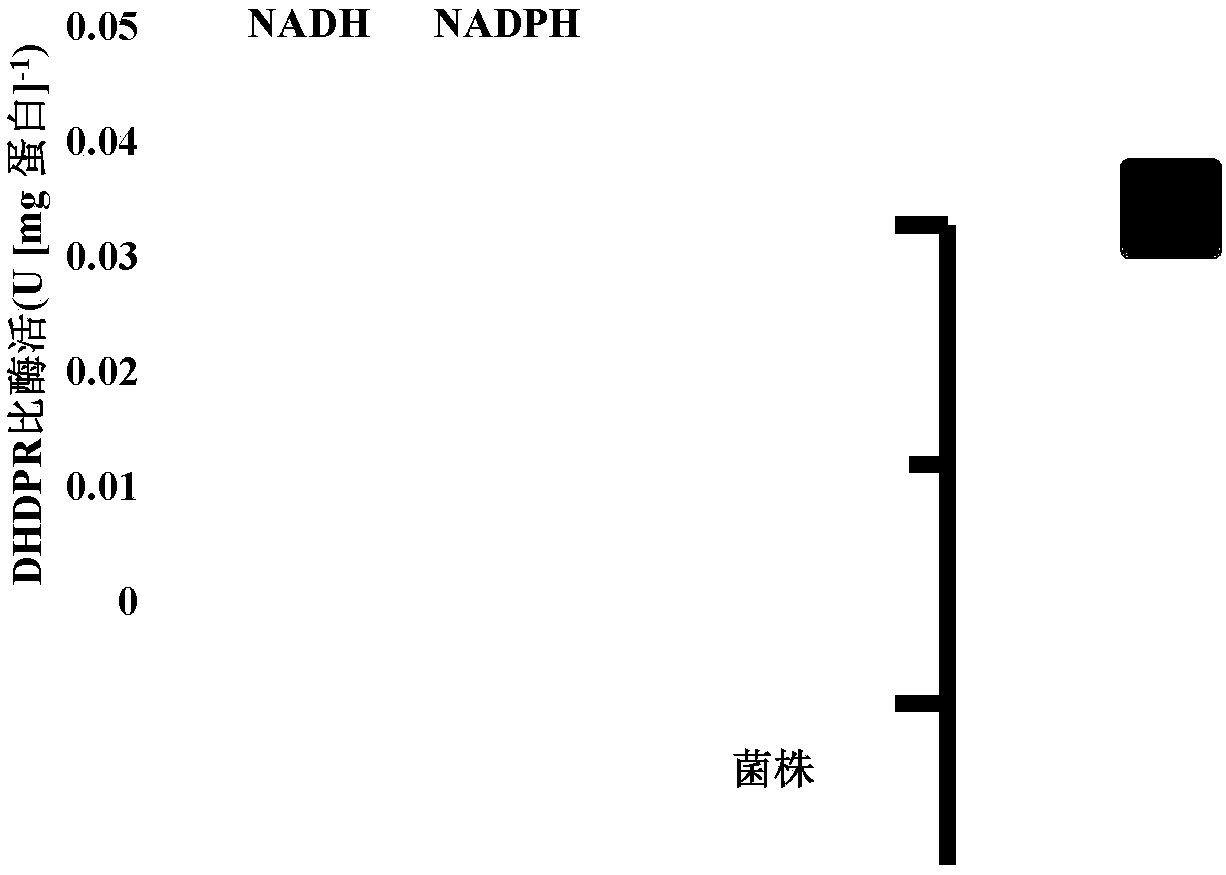

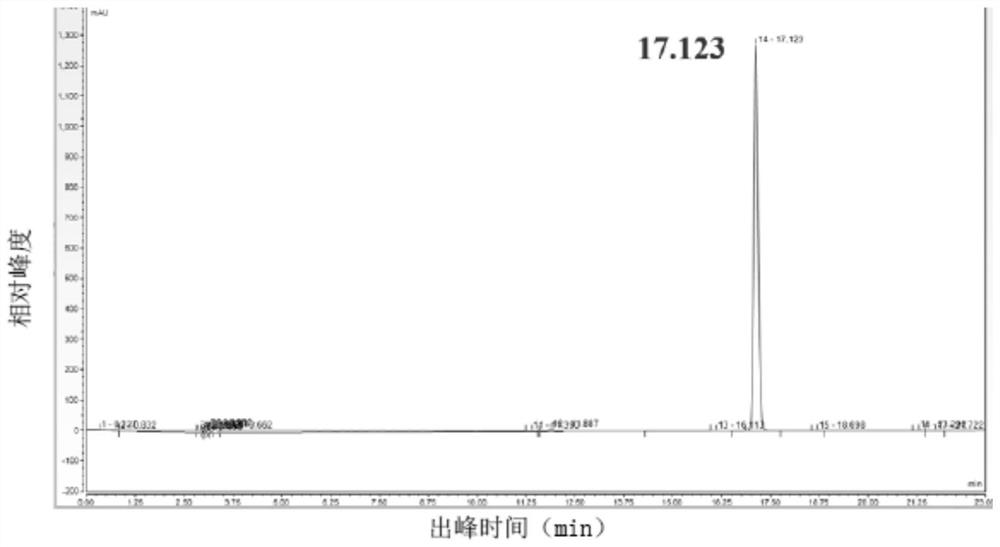

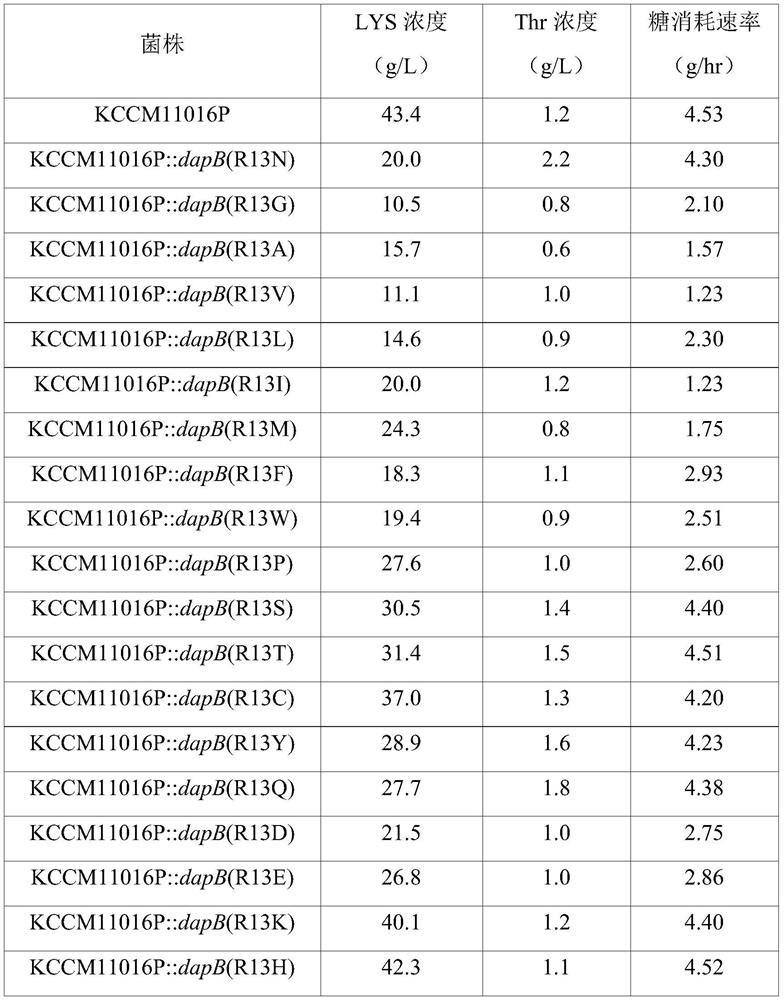

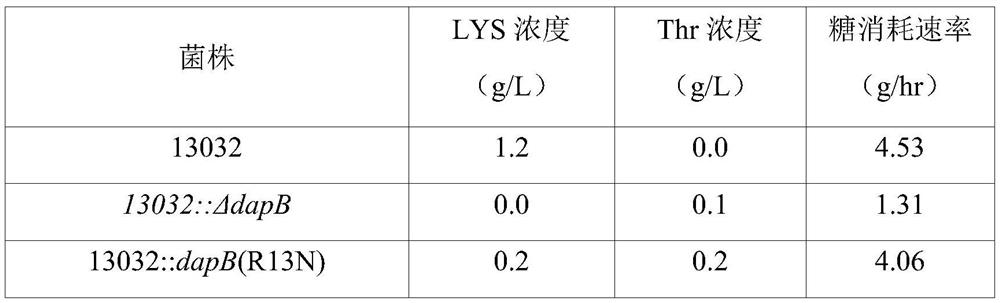

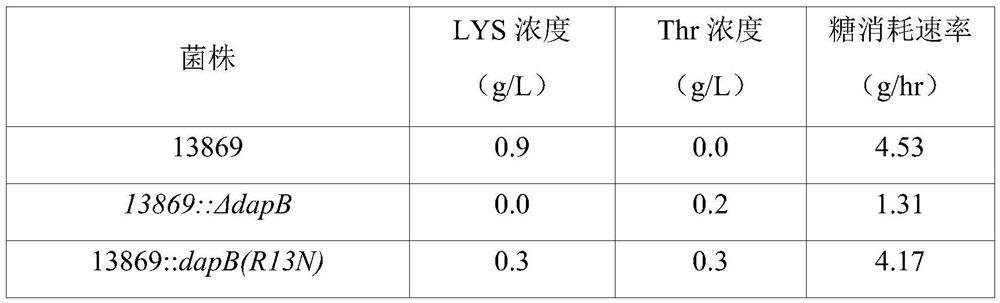

Method for performing genetic modification on DHDPR (Dihydrodipicolinic Acid Reductase) in corynebacterium glutamicum to increase lysine yield

InactiveCN107916246ADisadvantages of lifting undersupplyImprove the ability to accumulate L-lysineBacteriaMicroorganism based processesGenetic engineeringBacilli

The invention discloses a method for performing genetic modification on DHDPR (Dihydrodipicolinic Acid Reductase) in corynebacterium glutamicum to increase lysine yield and belongs to the fields of genetic engineering and enzyme engineering. By using the genetic engineering method, DHDPR coding genes dapB in corynebacterium glutamicum JL-6 are subjected to site-specific mutagenesis, and the DHDPRprotein structure is changed, so that the affinity of the DHDPR on different oxidation reduction cofactors is regulated, the defect that the requirement of NADP (H / +) is insufficient in the L-lysine synthesis process is overcome, and the ability of accumulating L-lysine in the strain is improved. According to shaking flask fermentation of recombinant bacteria, the accumulation amount of the L-lysine is 17.6g / L. According to the method disclosed by the invention, the affinity of the oxidation reduction cofactors of the DHDPR in the corynebacterium glutamicum is successfully changed, the defectthat the requirement of the NADP (H / +) is insufficient in the L-lysine synthesis process is overcome, and a new thinking is provided for breeding high-yield L-lysine strains.

Owner:JIANGNAN UNIV

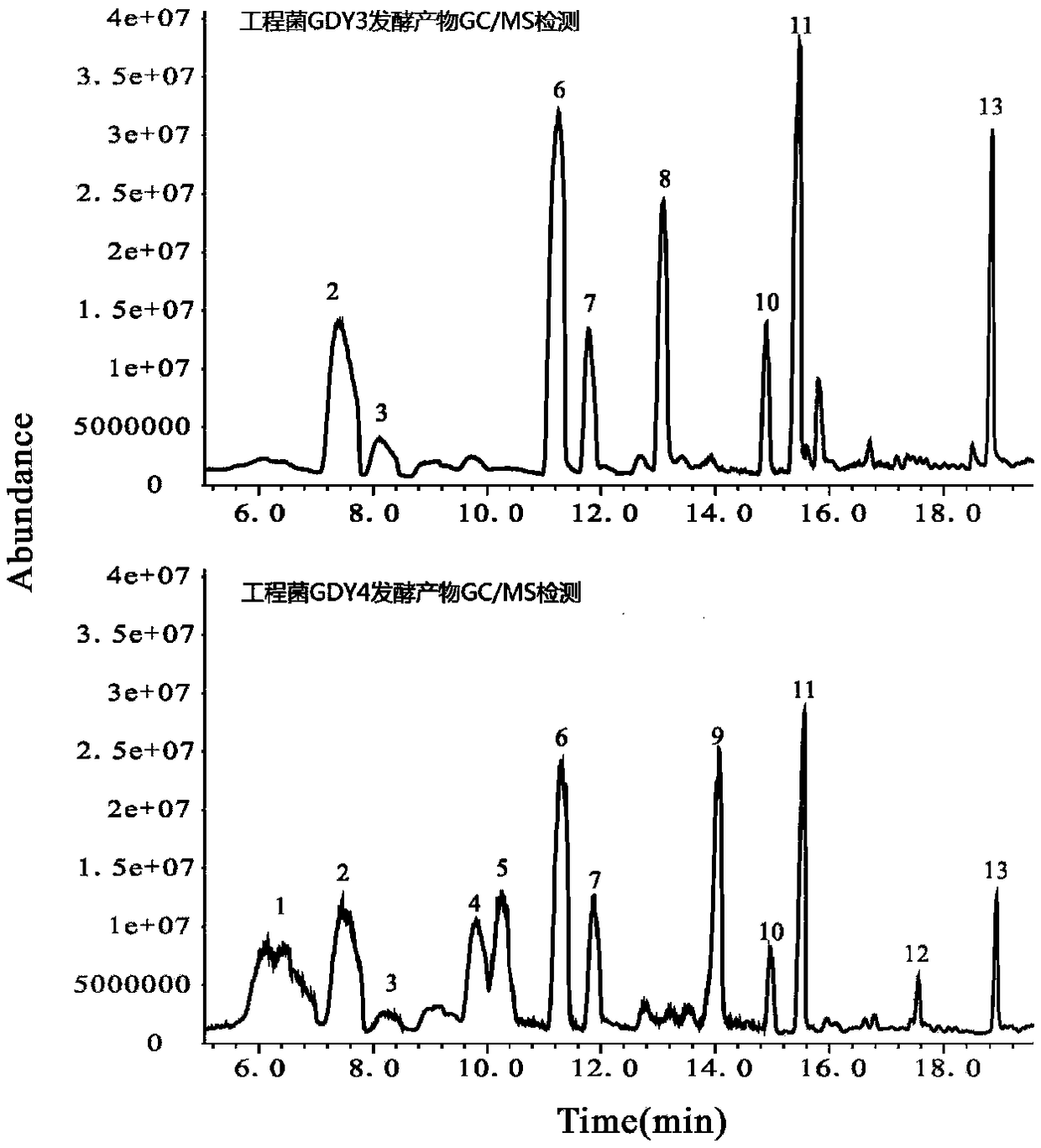

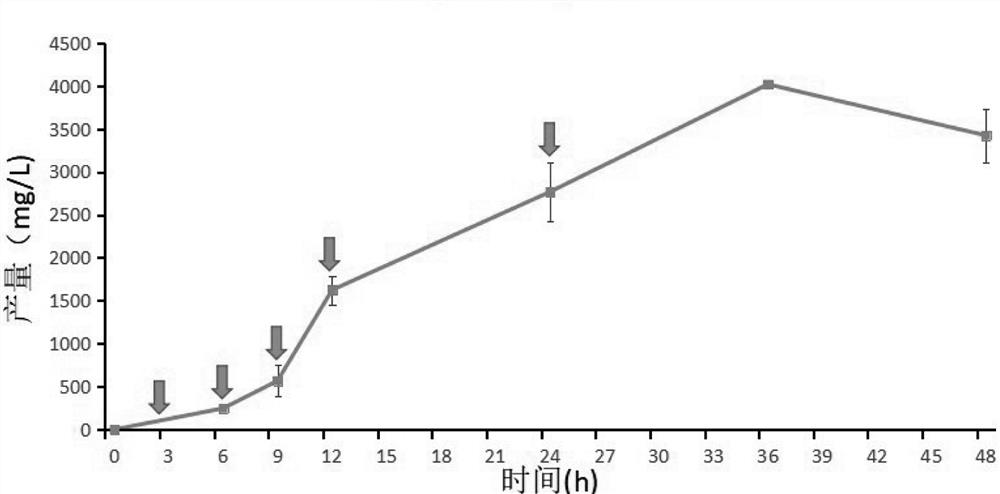

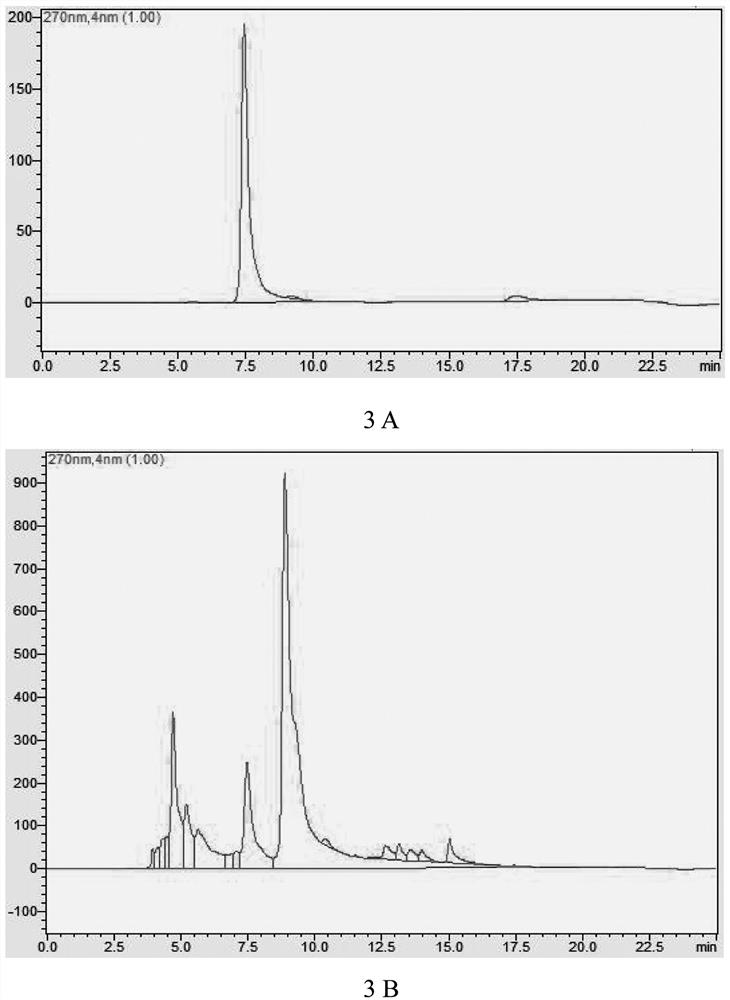

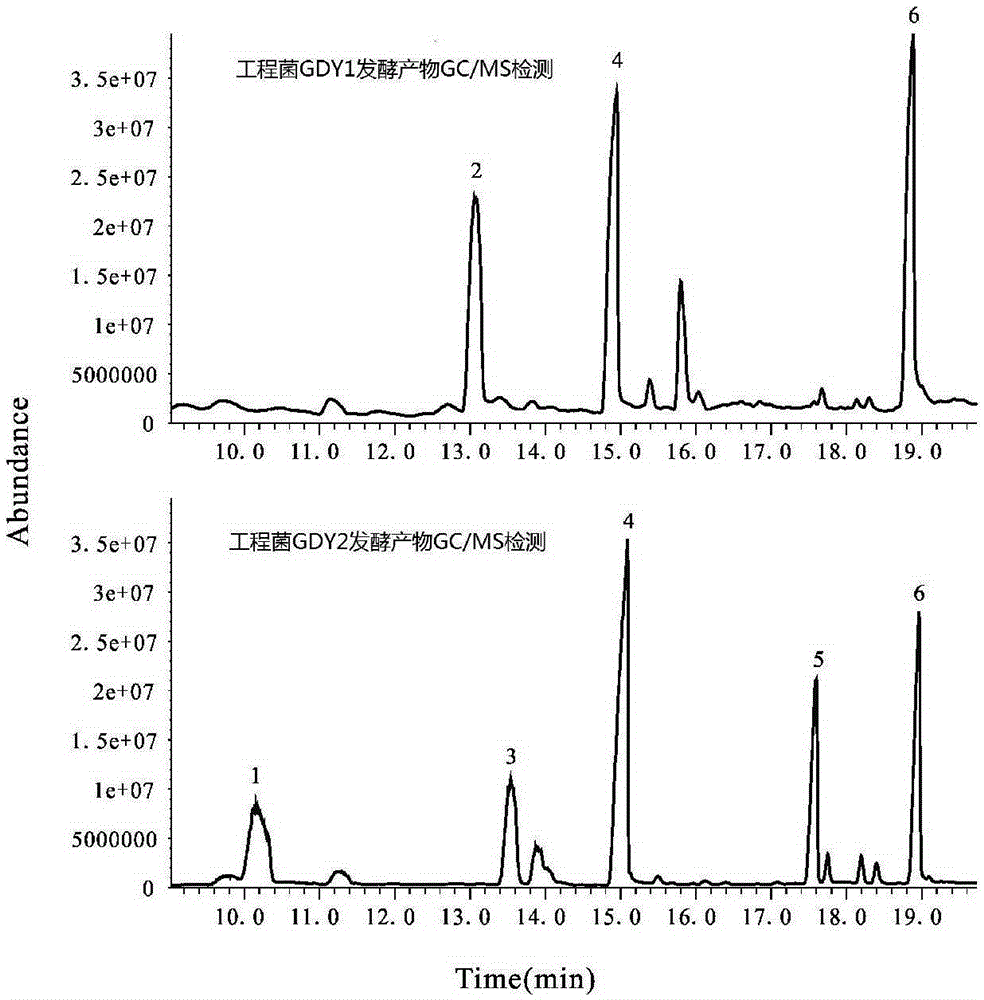

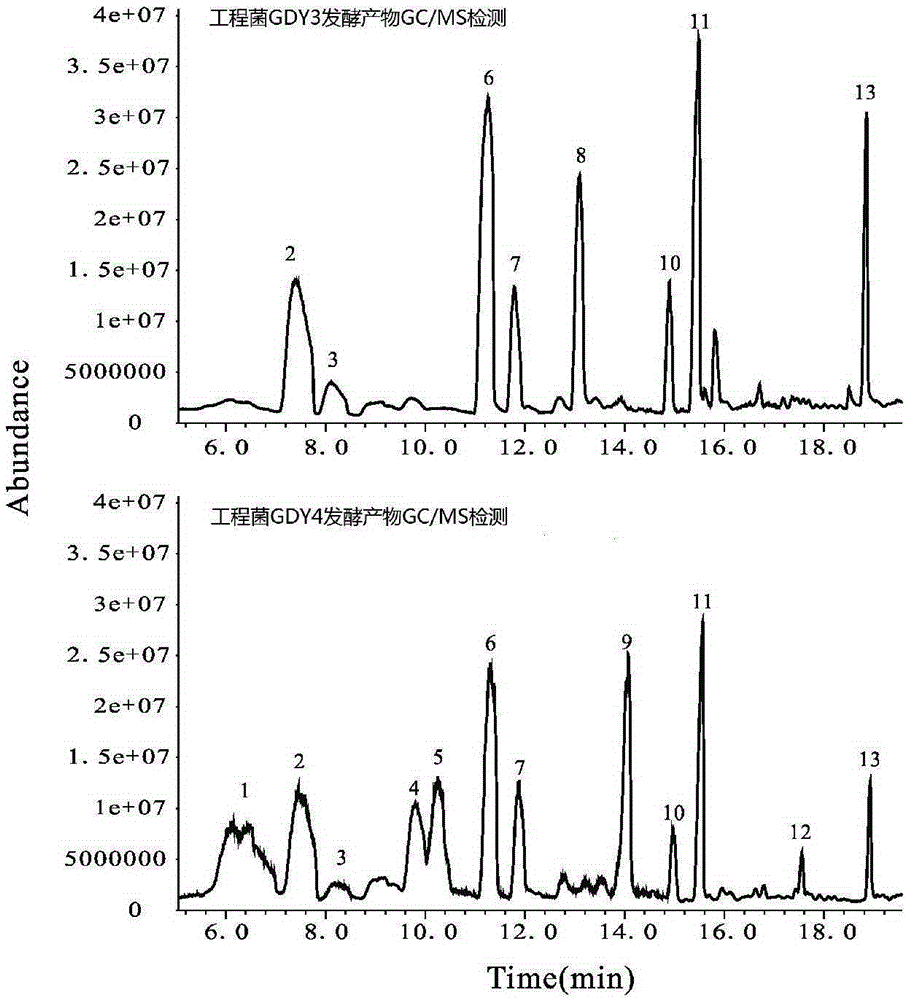

Genetically engineered bacterium for synthesizing vanillin and application of genetically engineered bacterium

PendingCN114181877AIncrease productionIncrease concentrationBacteriaTransferasesEnzyme GenePhosphoric acid

The invention relates to a genetically engineered bacterium for synthesizing vanillin. The genetically engineered bacterium comprises a path for synthesizing natural vanillin from vanillic acid: the natural vanillin is generated from the vanillic acid under the catalytic action of carboxylic acid reductase Car and phosphopantetheine transferase Sfp. According to the invention, a carboxylic acid reductase (Car) gene and a phosphopantetheine transferase (Sfp) gene are introduced into a host bacterium to successfully construct a genetically engineered bacterium capable of efficiently catalyzing the reduction of vanillic acid to generate vanillin; meanwhile, the yield of the natural vanillin is further increased in a mode of combining substrate / product tolerance domestication and whole-cell catalysis process optimization regulation. A plurality of repeated experiments show that the highest yield of vanillin produced by catalyzing vanillic acid through a biological method in the currently reported related research can reach 4.05 g / L, and the method has a great industrial application prospect in efficient production of vanillin through the biological method.

Owner:BEIJING UNIV OF CHEM TECH

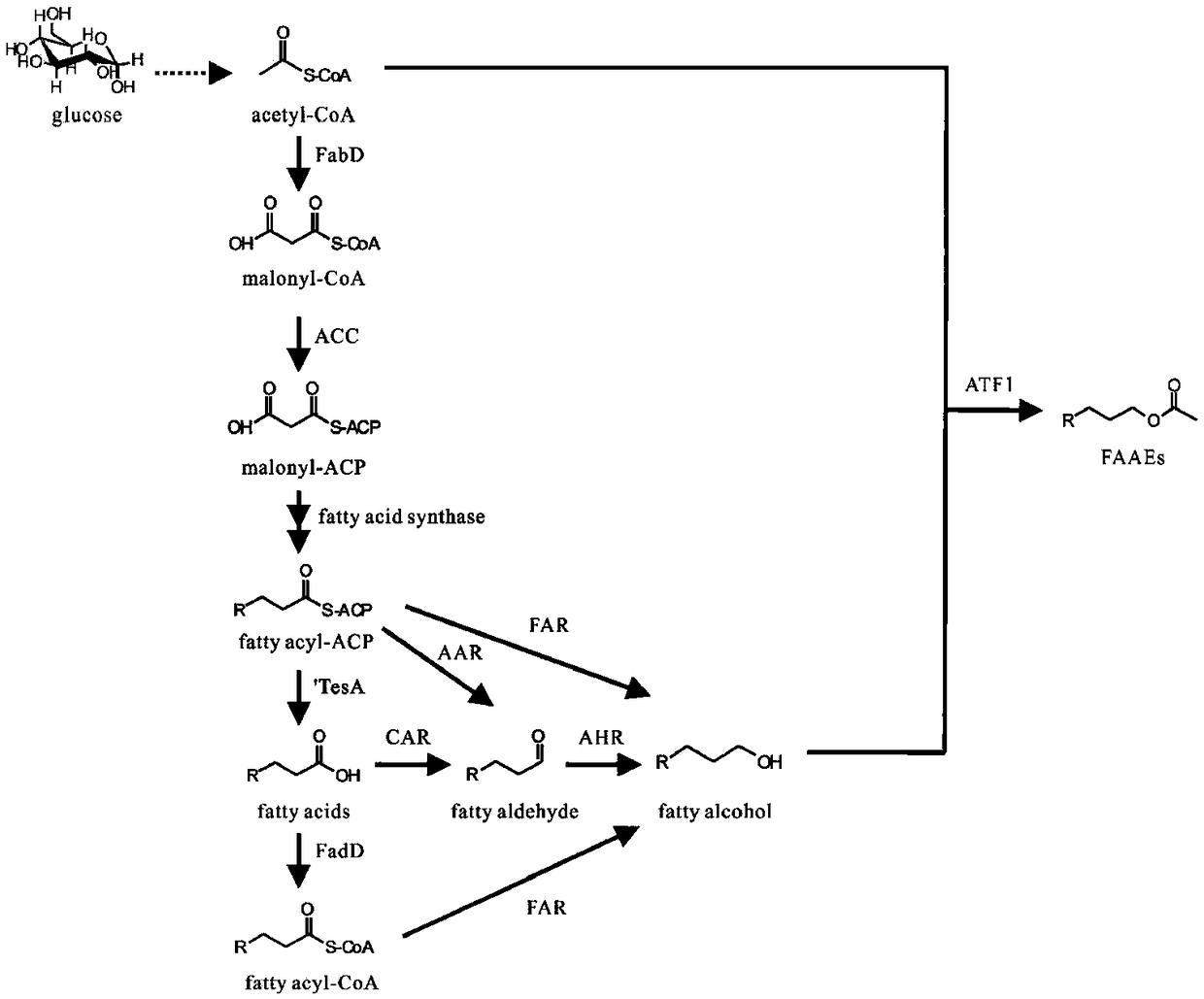

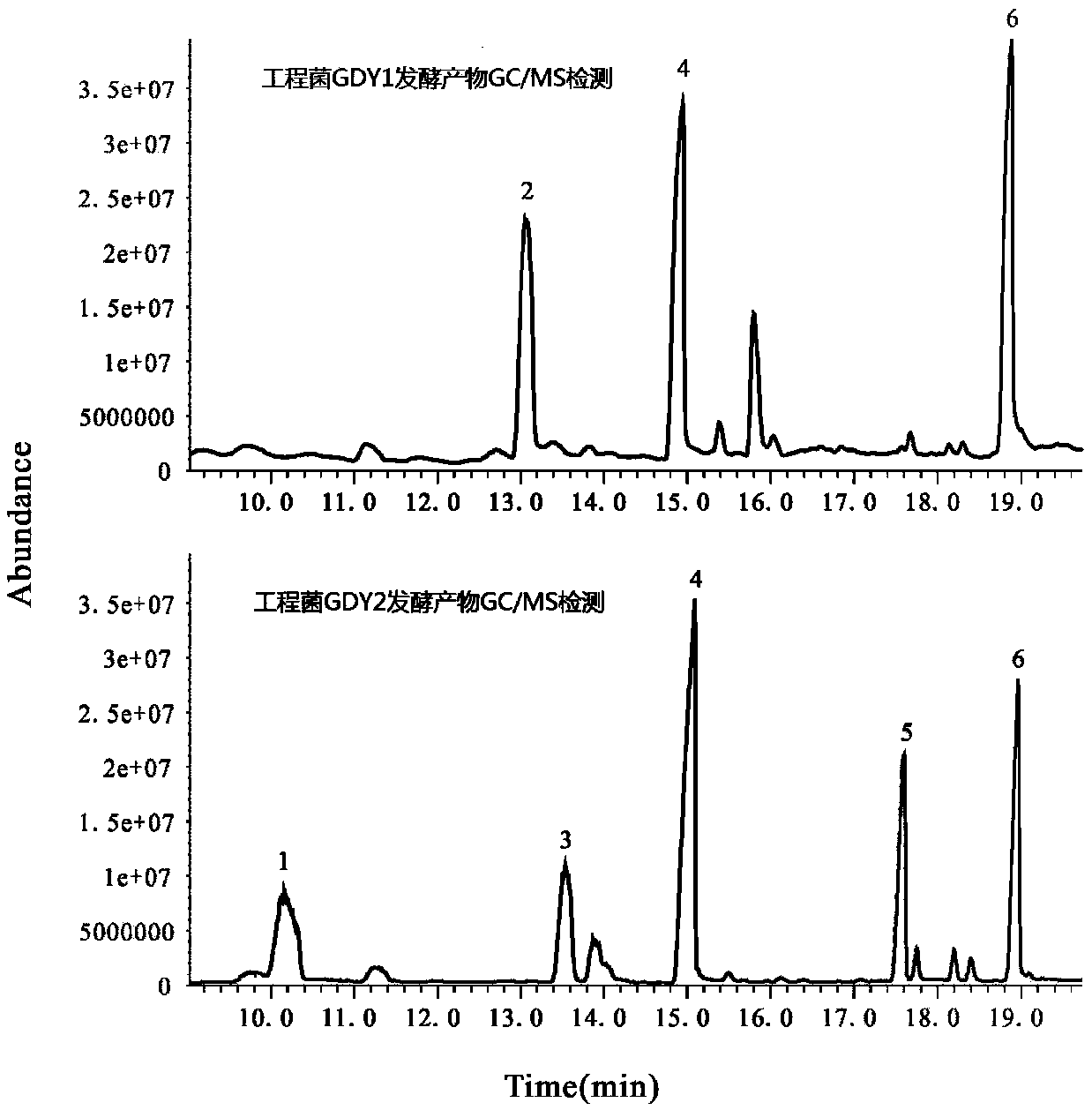

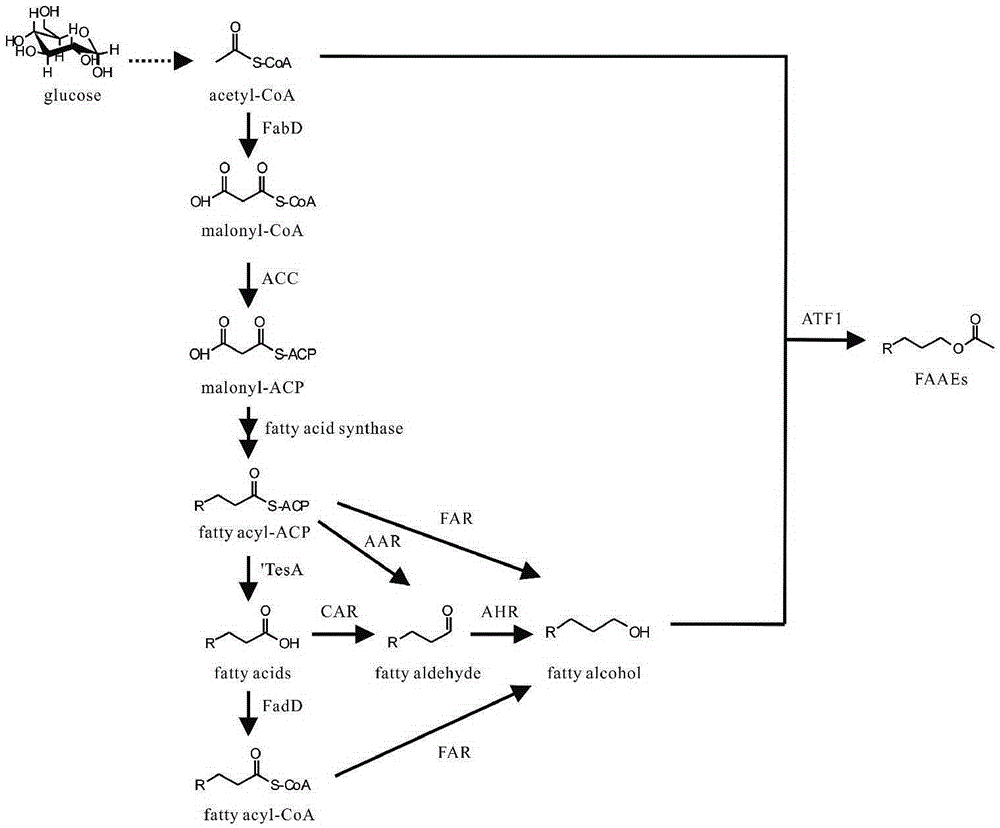

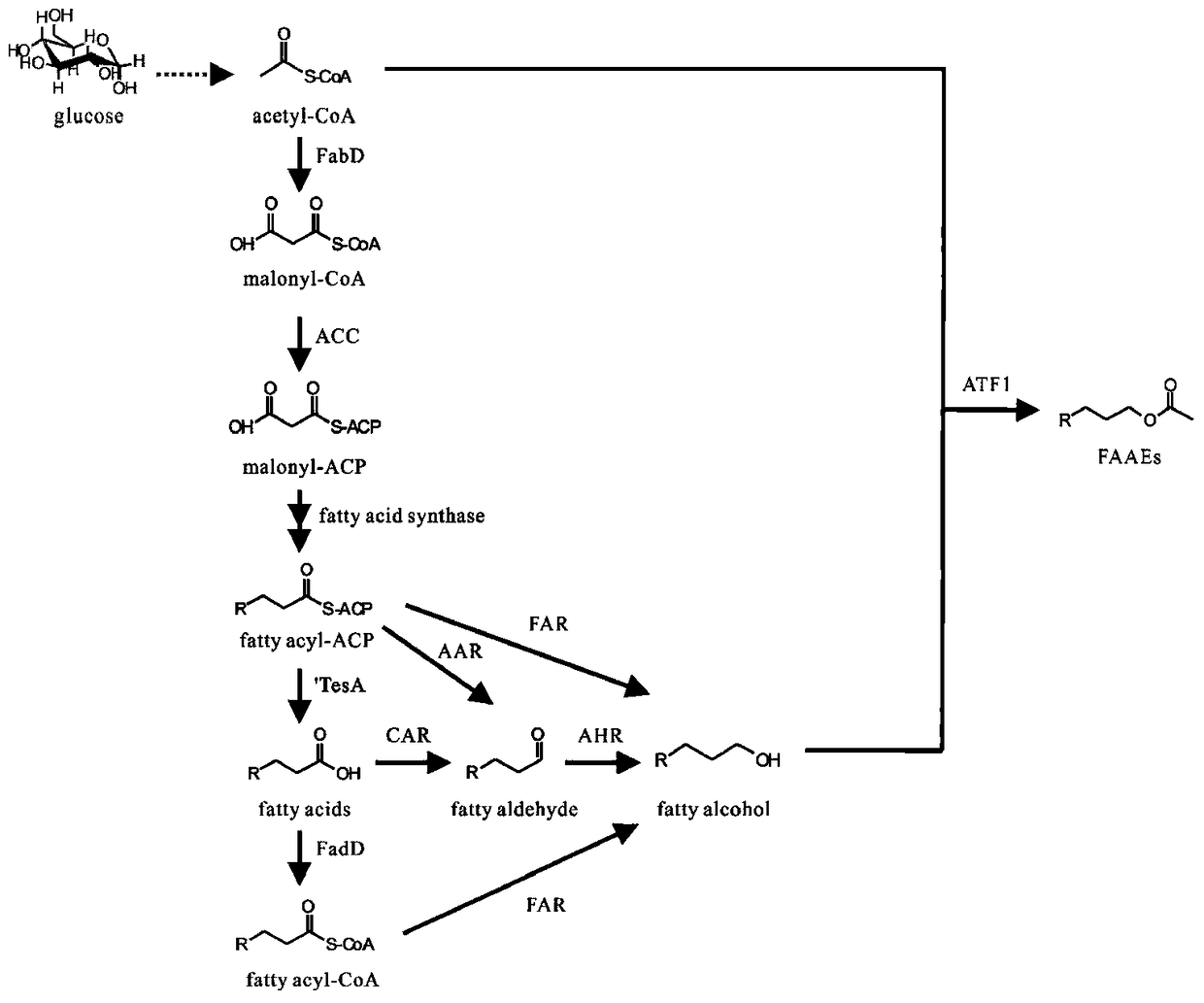

Method for synthesizing fatty alcohol acetates base on fatty acids in microorganisms in vivo

ActiveCN109234295AFast growthGenetic manipulation technology is matureBiofuelsFermentationMicrobial transformationIn vivo

A method for synthesize pheromone fatty alcohol acetate ester based on three intermediate product of fatty acid metabolism pathway in microorganism includes such steps as high expression of fatty acidacyl ester in microorganism, high expression of fatty acid acyl ester in microorganism, high expression of fatty acid acyl ester in microorganism, high expression of fatty acid acyl ester in microorganism, high expression of fatty acid acyl ester in microorganism, high expression of fatty acid acyl ester in microorganism, and high expression of fatty acid acyl ester in microorganism. ACP reductase AAR, carboxylic acid reductase CAR, acyl-CoA reductase FAR and aldehyde reductase AHR, respectively. ACP, fatty acid or acyl-CoA producing fatty alcohol. At last, the pheromone fatty alcohol acetatewas synthesized by the reaction of fatty alcohol and acetyl-CoA with high expression of alcohol acetyltransferase ATF1 in fatty alcohol-producing engineering bacteria. The invention can realize microbial conversion from glucose to fatty alcohol acetate, and provides a feasible path for large-scale biosynthesis of fatty alcohol acetate.

Owner:GANNAN NORMAL UNIV

Method of producing l-lysine

InactiveUS20110065153A1Improve the L-lysine-producing ability and the growth speed of a coryneform bacteriumImprove scalabilityBacteriaTransferasesDiaminopimelate decarboxylaseDiaminopimelate dehydrogenase

The ability and speed with which a coryneform bacterium can produce L-lysine are improved when the coryneform bacterium contains an aspartokinase in which feedback inhibition by L-lysine and L-threonine is substantially desensitized. This is accomplished by successively enhancing the DNA coding for dihydrodipicolinate reductase, the DNA coding for dihydrodipicolinate synthase, the DNA coding for diaminopimelate decarboxylase, and the DNA coding for diaminopimelate dehydrogenase.

Owner:AJINOMOTO CO INC

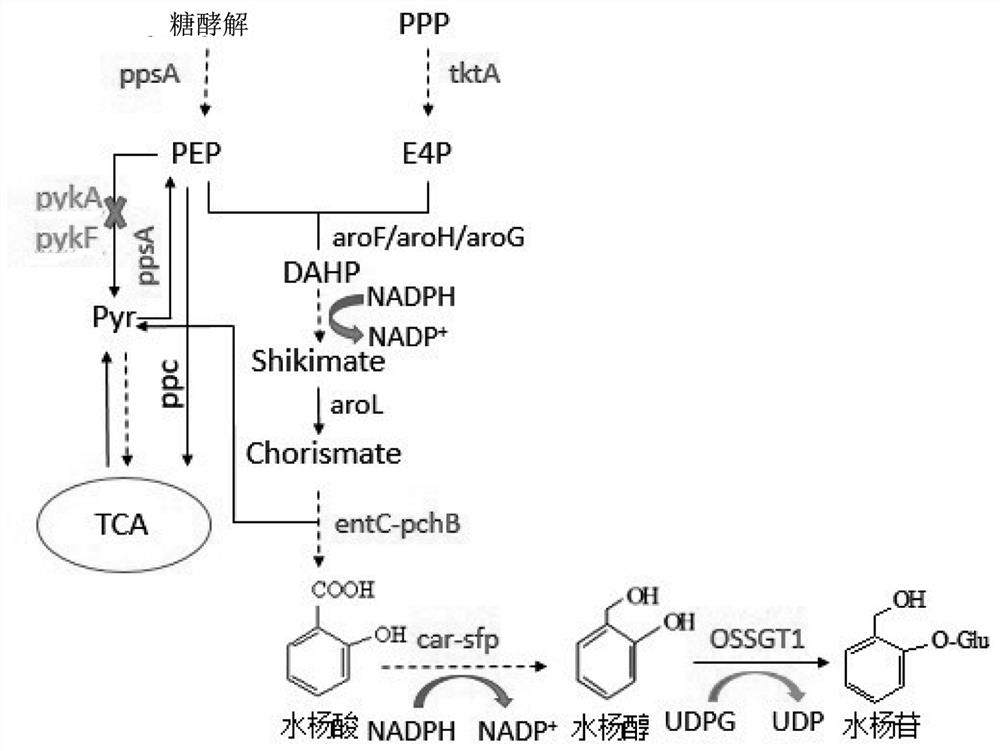

Engineering bacterium for synthesizing salicin as well as construction method and application of engineering bacterium

The invention provides an engineering bacterium suitable for salicin, which comprises a host and a recombinant plasmid vector, and the recombinant plasmid vector is connected with a gene for expressing and coding glucosyltransferase. The recombinant plasmid vector is also connected with a gene for coding carboxylic acid reductase and phosphoryl transferase, which is co-expressed with the gene for coding glucosyltransferase. The recombinant plasmid vector is also connected with genes for over-expressing and coding shikimic acid kinase, pyruvate kinase, transketolase, 3-deoxy-7-phosphoenanthate synthase, iso-chorismate pyruvate lyase and isochorismate synthase; and the host is also knocked out of genes for coding pykA and pykF, so that the yield of salicin is increased. The invention also provides a construction method and an application of the engineering bacterium for synthesizing salicin. By utilizing the engineering bacteria for synthesizing the salicin, the salicin is produced by using glucose and / or glycerol and other carbon sources, so that efficient biosynthesis of the salicin is realized.

Owner:BEIJING UNIV OF CHEM TECH

Method for synthesizing fatty alcohol acetic acid ester in microorganism

ActiveCN105331647AFast growthGenetic manipulation technology is matureBiofuelsMicroorganism based processesMicrobial transformationCarboxylic acid

The invention discloses a method for synthesizing pheromone fatty alcohol acetic acid ester in a microorganism, based on a fatty acid metabolic pathway and by using three intermediate products as precursor molecules. The method includes: highly expressing acyl-ACP reductase AAR, carboxylic acid reductase CAR, acyl-CoA reductase FAR and aldehyde reductase AHR in the microorganism to respectively obtain engineering bacteria capable of reducing acyl-ACP, fatty acid or acyl-CoA fat generating alcohol; highly expressing alcohol acetyltransferase ATF1 in the fat-generating alcohol engineering bacteria to catalyze reaction of fatty alcohol and acetyl coenzyme A to synthesize the pheromone fatty alcohol acetic acid ester. By the method, microbial conversion from glucose to the fatty alcohol acetic acid ester can be realized, and a feasible way is provided for biologically synthesizing the fatty alcohol acetic acid ester on a large scale.

Owner:GANNAN NORMAL UNIV

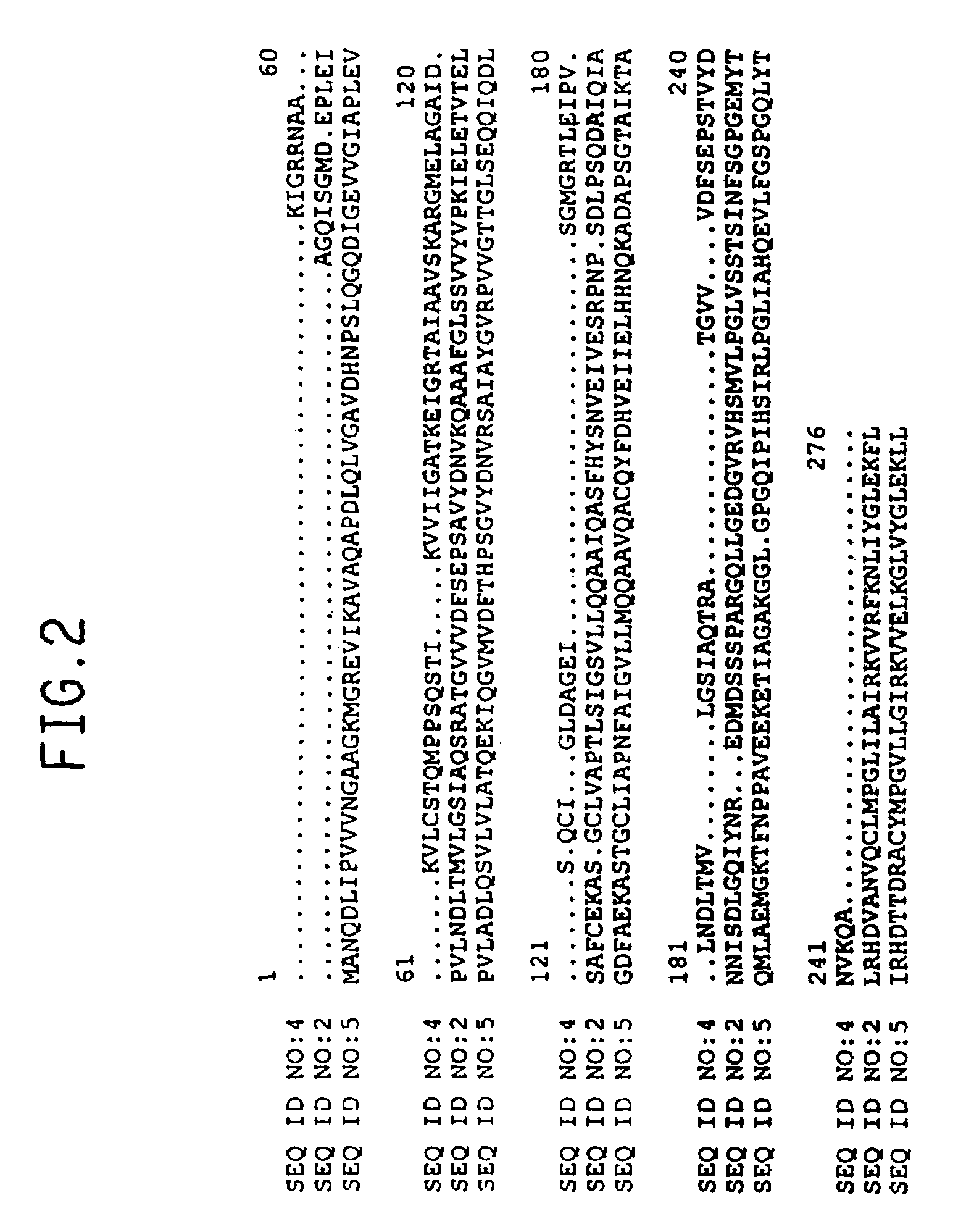

Plant amino acid biosynthetic enzymes

InactiveUS7022895B2Inhibitory activityBacteriaTransferasesAntisense OrientationS-Adenosyl-l-methionine

This invention relates to an isolated nucleic acid fragment encoding a plant enzyme that catalyze steps in the biosynthesis of lysine, threonine, methionine, cysteine and isoleucine from aspartate, the enzyme a member selected from the group consisting of: dihydrodipicolinate reductase, diaminopimelate epimerase, threonine synthase, threonine deaminase and S-adenosylmethionine synthetase. The invention also relates to the construction of a chimeric gene encoding all or a portion of the enzyme, in sense or antisense orientation, wherein expression of the chimeric gene results in production of altered levels of the enzyme in a transformed host cell.

Owner:EI DU PONT DE NEMOURS & CO

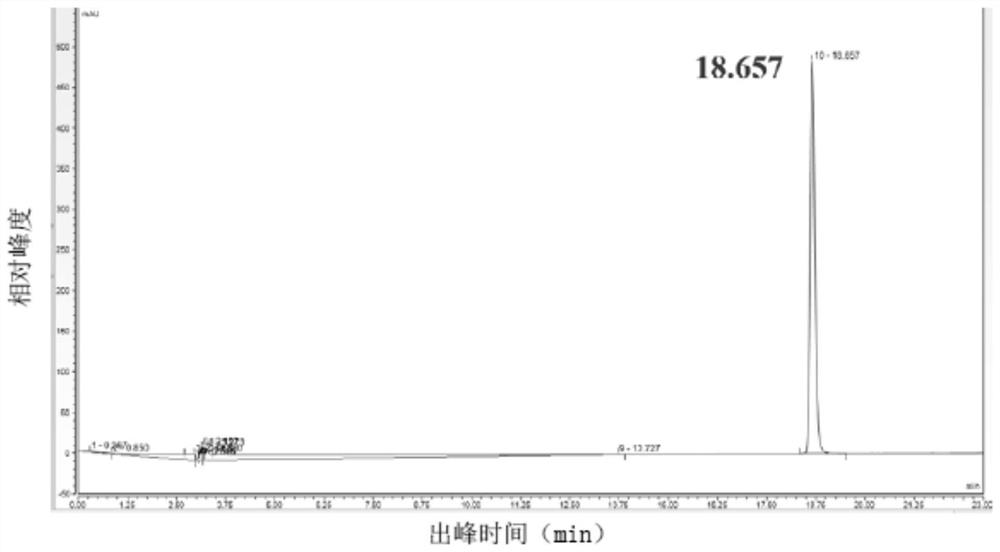

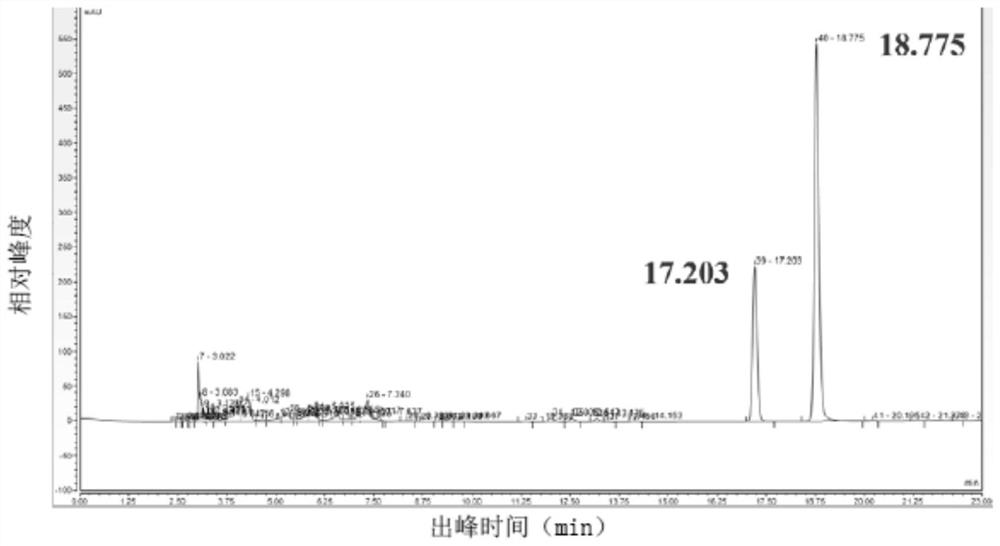

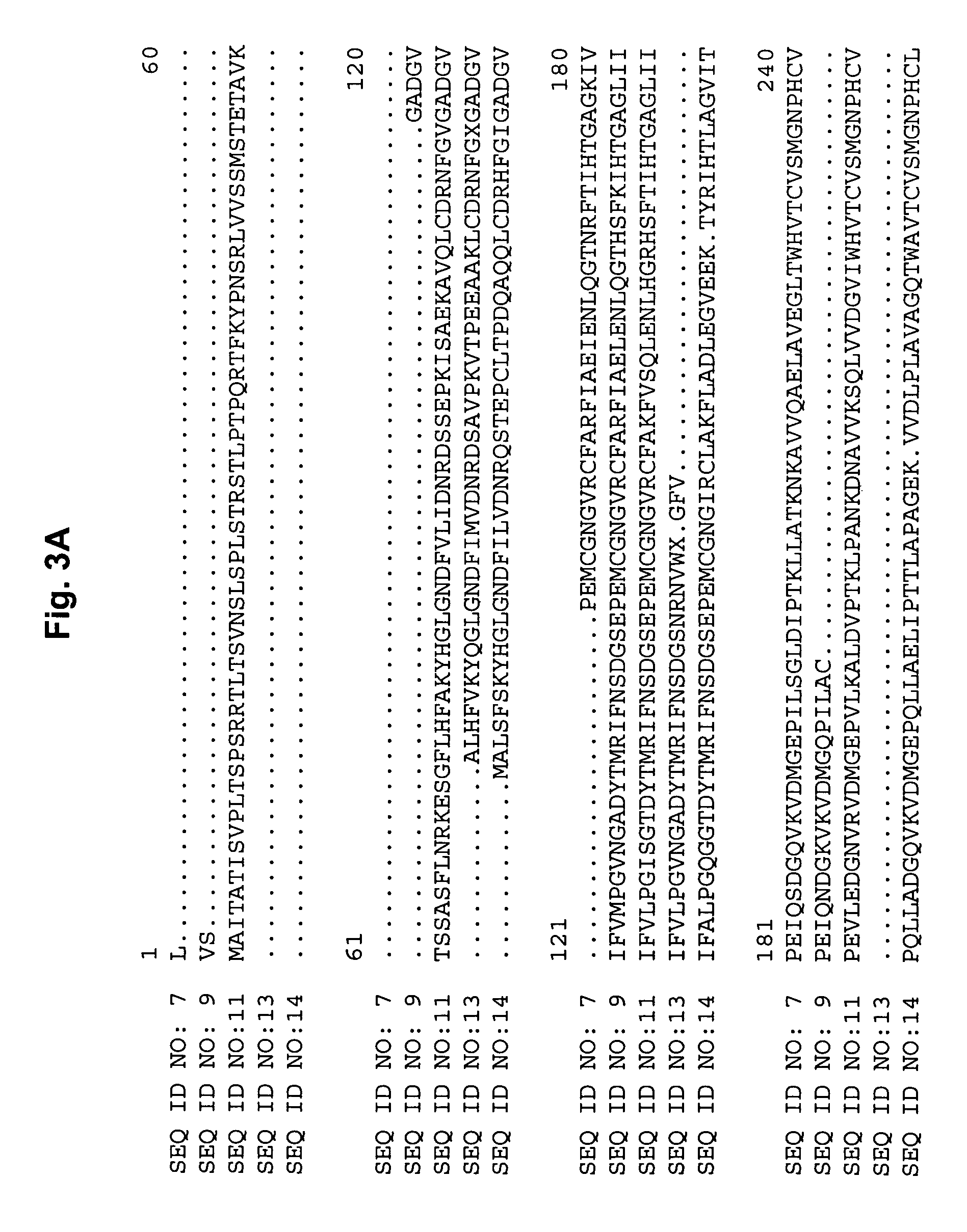

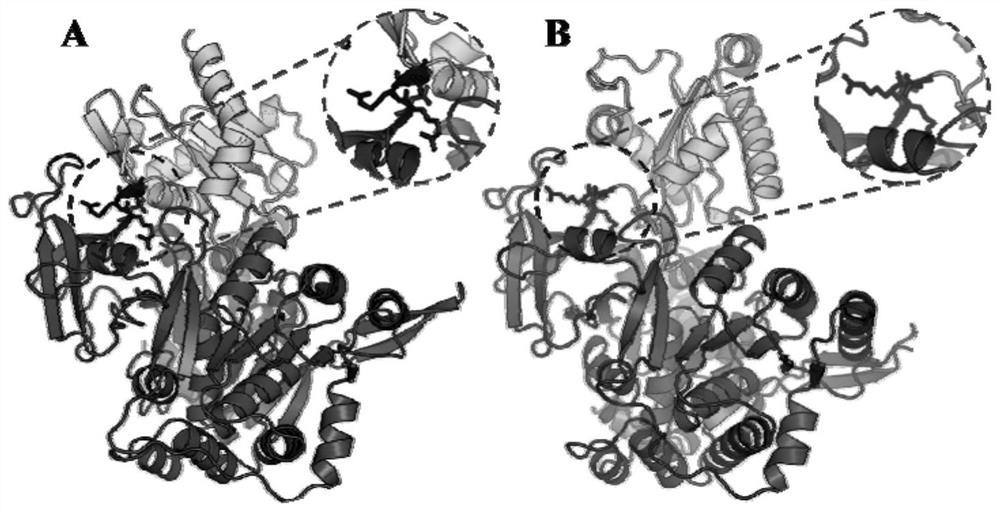

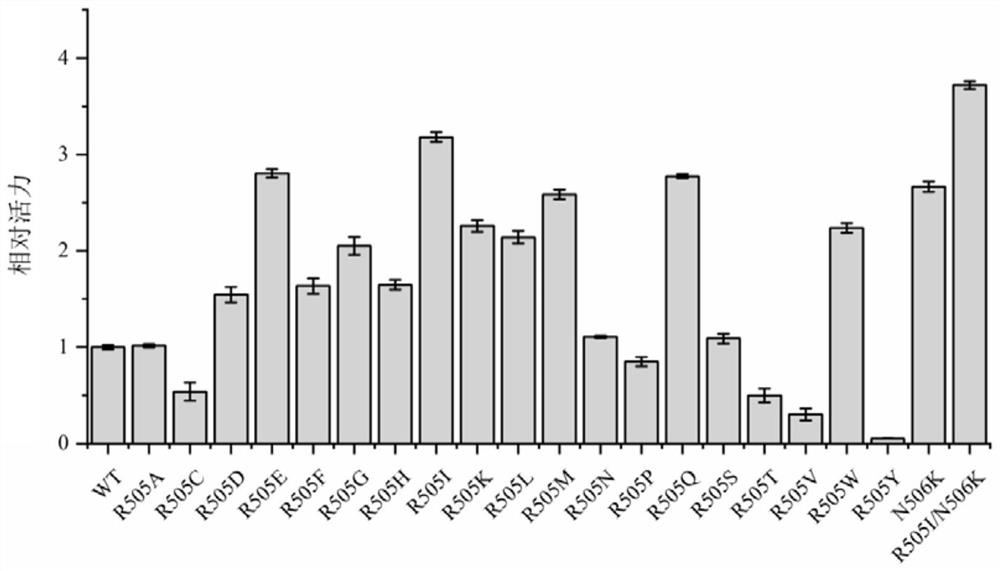

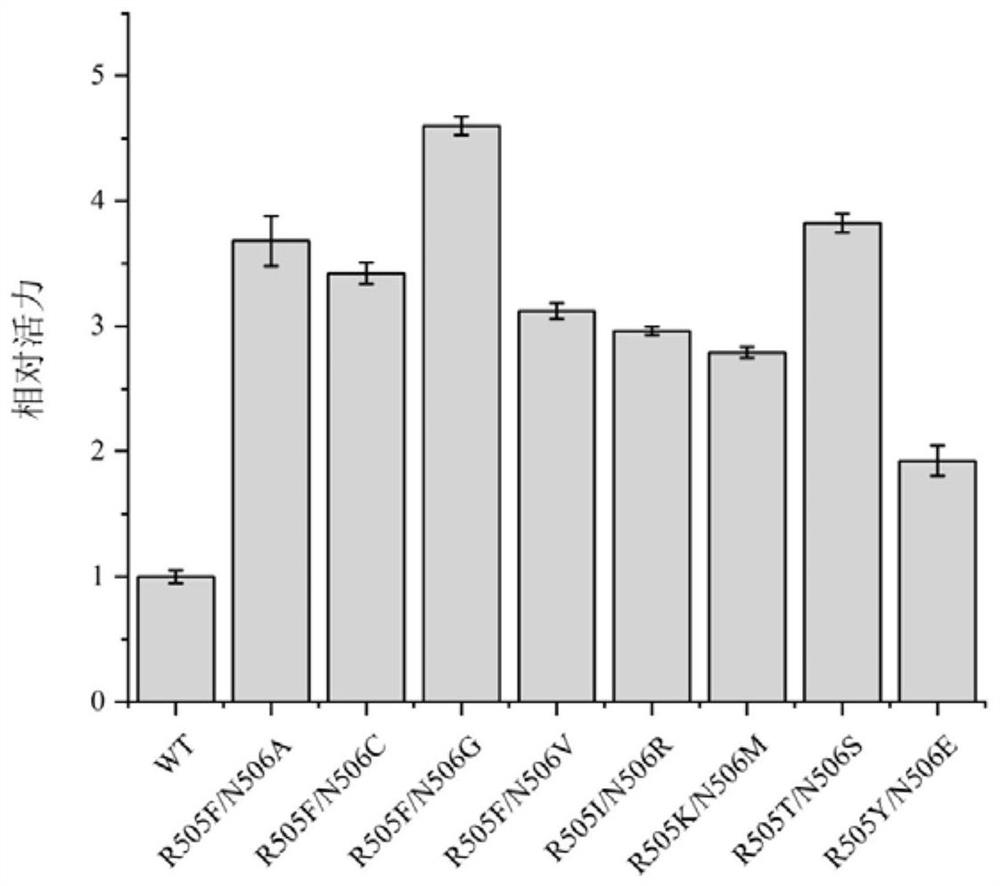

Carboxylic acid reductase mutant with improved catalytic activity and coding gene, genetically engineered bacterium and application thereof

ActiveCN113604444AHigh catalytic activityIncrease vitalityBacteriaMicroorganism based processesCarboxylic acid reductaseVanillic acid

The invention discloses a carboxylic acid reductase mutant with improved catalytic activity and a coding gene, a genetically engineered bacterium and application thereof. Wild carboxylic acid reductase as shown in SEQ ID NO.1 is taken as a basis, and site-specific mutagenesis is carried out as follows: mutants R505E, R505I, R505M and R505Q formed by R mutation at the 505th site; a mutant N506K formed by N mutation at the 506th site; and mutants R505I / N506K, R505F / N506G, R505F / N506A, R505F / N506C, R505F / N506V, R505I / N506R, R505K / N506M, R505T / N506S and R505Y / N506E formed by simultaneous R mutation at the 505th site and N mutation at the 506th site. The mutants obviously improve the activity of catalyzing vanillic acid to vanillic aldehyde, and have wide application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

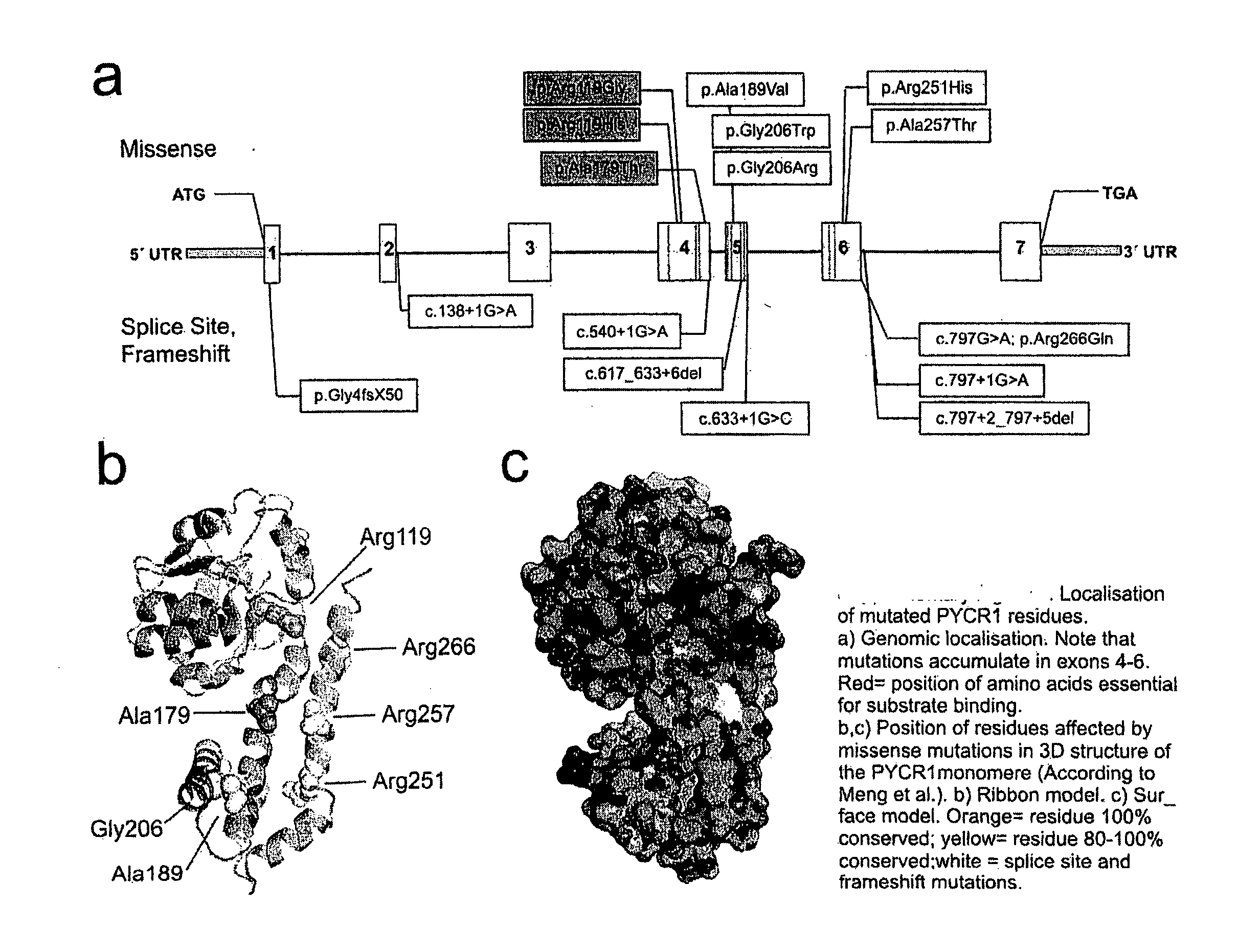

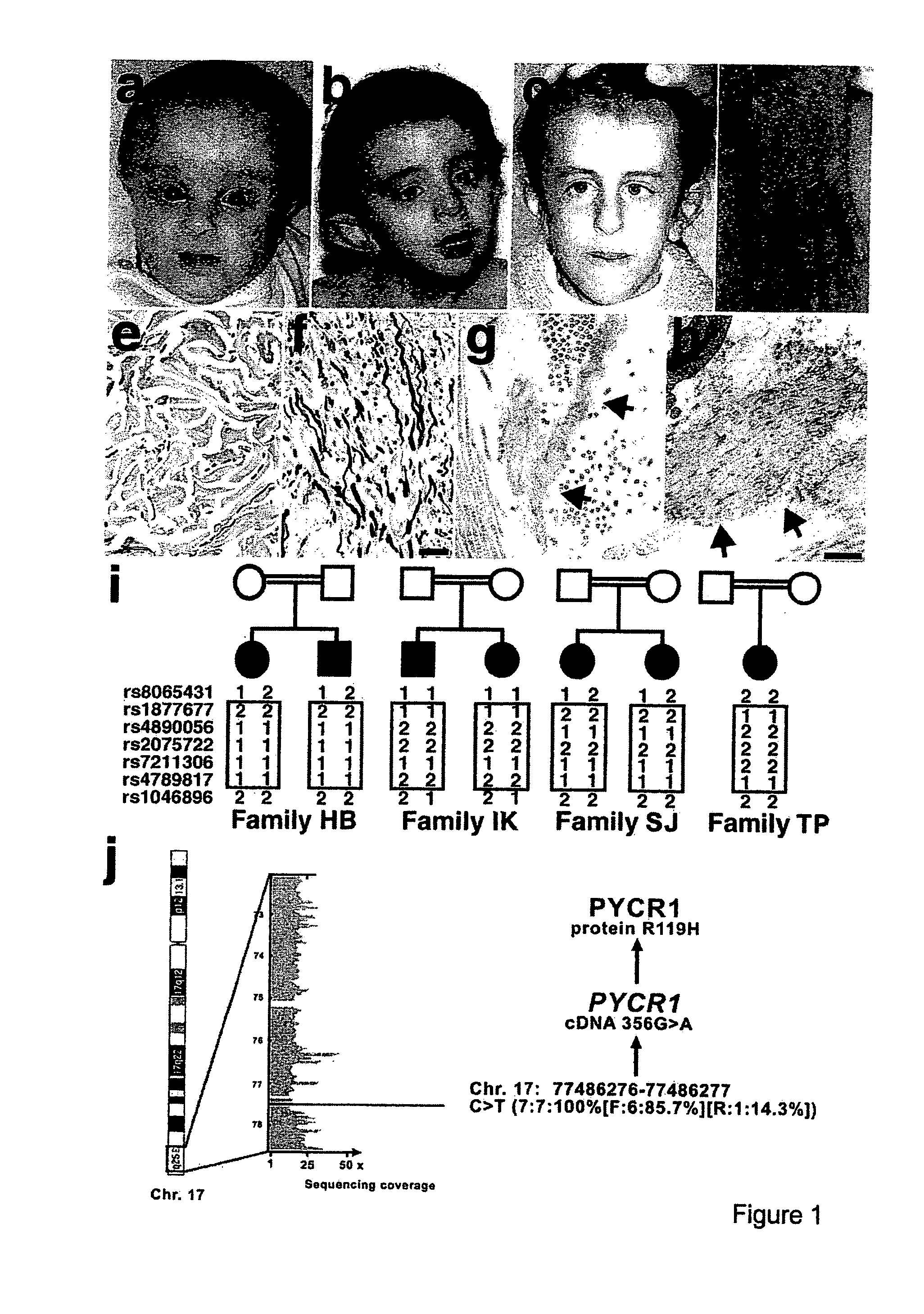

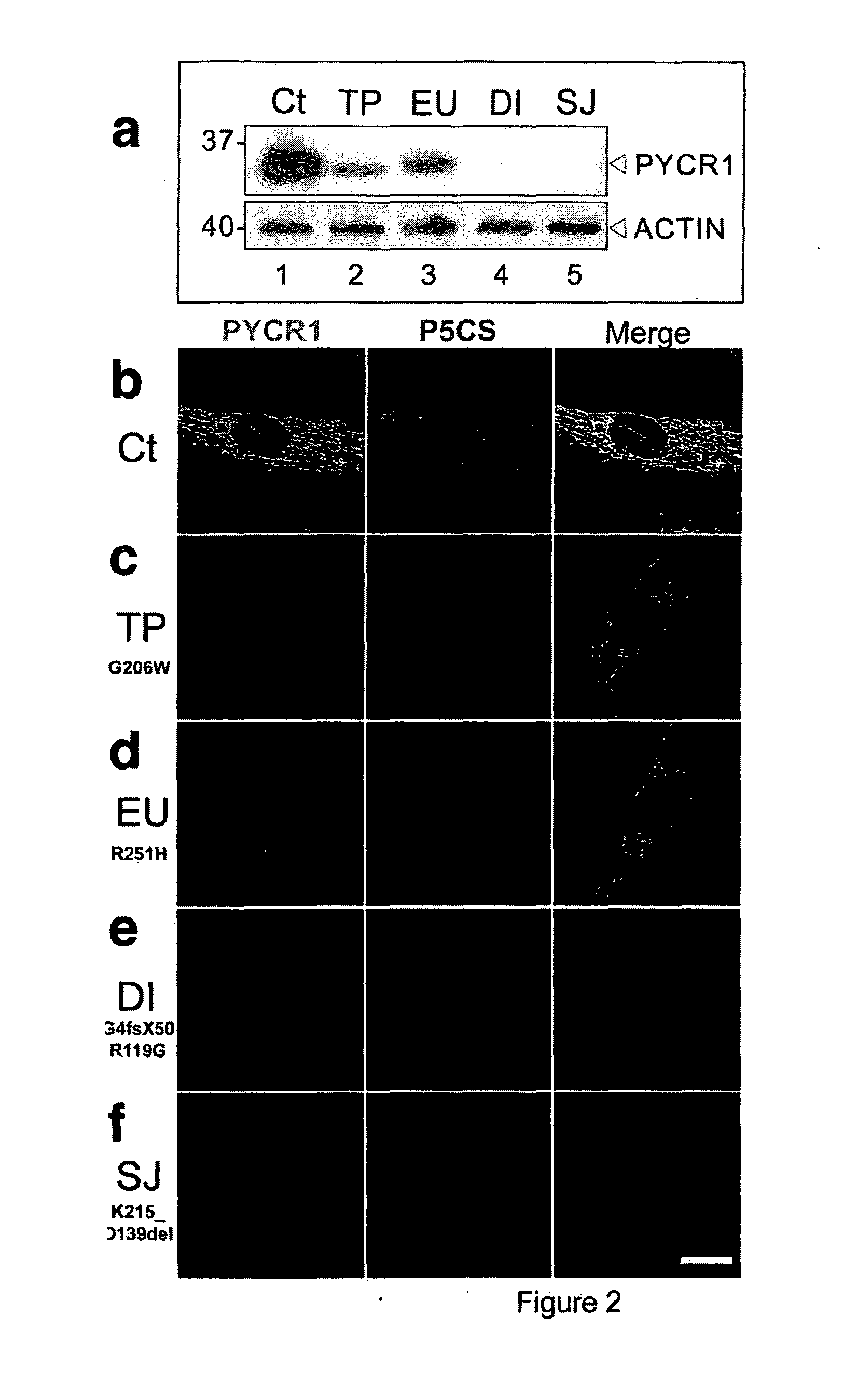

Muteins of the pyrroline-5-carboxylate reductase 1

InactiveUS20120144511A1Improve comprehensive applicabilityIncrease productionOrganic active ingredientsPeptide/protein ingredientsCarboxylic acid reductaseMutated protein

The invention relates to muteins of the pyrroline-5-carboxylate reductase 1 (PYCR1), to nucleic acid molecules comprising a nucleotide sequence encoding such muteins, to methods of determining in a subject a predisposition of having an age related disorder associated with PYCR1, to methods of identifying a compound capable of modifying the expression of PYCR1 and methods of treating a subject having an age-related disorder associated with PYCR1. The invention further relates to a genetically modified animal and a method of modifying the expression of the PYCR1 gene in an animal.

Owner:AGENCY FOR SCI TECH & RES

Method for producing 1, 6-hexanediol through whole-cell catalysis, recombinant microorganism and application of recombinant microorganism

ActiveCN114606169AIncrease productionShort reaction timeBacteriaTransferasesEscherichia coliCarboxylic acid reductase

The invention relates to the technical field of biochemical engineering, and particularly discloses a method for producing 1, 6-hexanediol through whole-cell catalysis, a recombinant microorganism and application of the recombinant microorganism. Compared with an original strain, the recombinant microorganism provided by the invention has the advantages that aldehyde reductase yahk is overexpressed, carboxylic acid reductase MpCAR and 4 '-phosphoric acid panthenyl aminotransferase sfp are expressed, and the original strain is escherichia coli. The recombinant Escherichia coli obtained by introducing exogenous carboxylic acid reductase and 4 '-phosphoric acid panthenotransferase into Escherichia coli and overexpressing aldehyde reductase is used for whole-cell catalysis, 1, 6-hexanediol can be produced from 1, 6-adipic acid under mild conditions, and the method has a very wide application prospect.

Owner:TSINGHUA UNIV

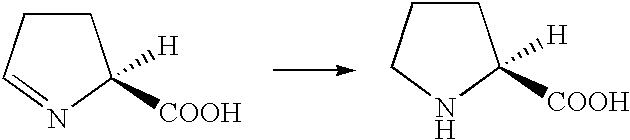

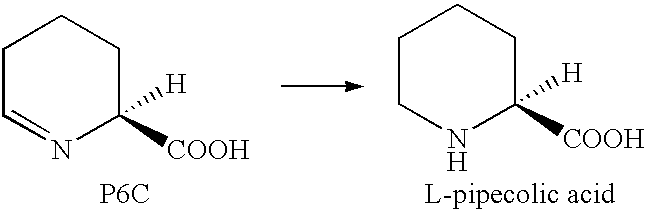

Process for the biological production of L-pipecolic acid

InactiveUS7022502B2Efficient productionReduce P6CBacteriaOxidoreductasesEscherichia coliPhenylacetic acid

A process for the production of L-pipecolic acid which comprises the step of reducing delta-1-piperideine-6-carboxylic acid by the use of pyrroline-5-carboxylate reductase. The delta-1-piperideine-6-carboxylic acid is obtained by the step of converting L-lysine by the use of lysine 6-aminotransferase encoded by a gene of Flavobacterium lutescens. The steps of reducing delta-1-piperideine-6-carboxylic acid and the converting of L-lysine into L-pipecolic acid by the use of lysine 6-aminotransferase are carried out by using a bacterium transformed with a gene encoding lysine 6-aminotransferase wherein such bacterium comprises pyrroline-5-carboxylate reductase encoded by a gene of Escherichia coli or a coryneform bacterium. A recombinant bacterium which can be used in this production process is also provided. Thus, the present invention can provide an efficient biological process for the production of L-pipecolic acid (or 2-piperidinecarboxylic acid).

Owner:MICROBIOPHARM JAPAN

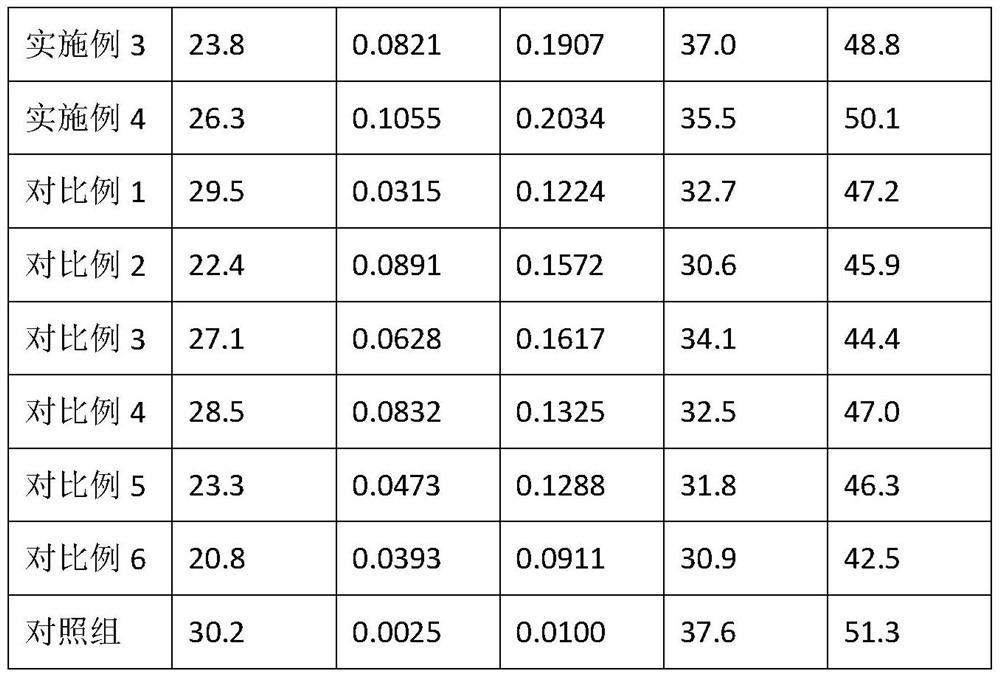

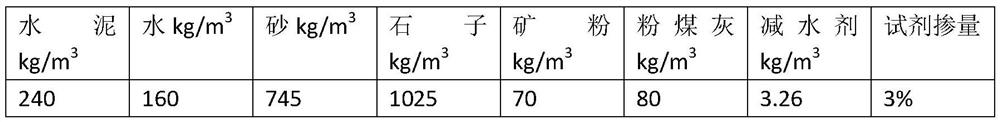

A reagent for inhibiting shrinkage of cement-based materials

Owner:贵州凯襄新材料有限公司

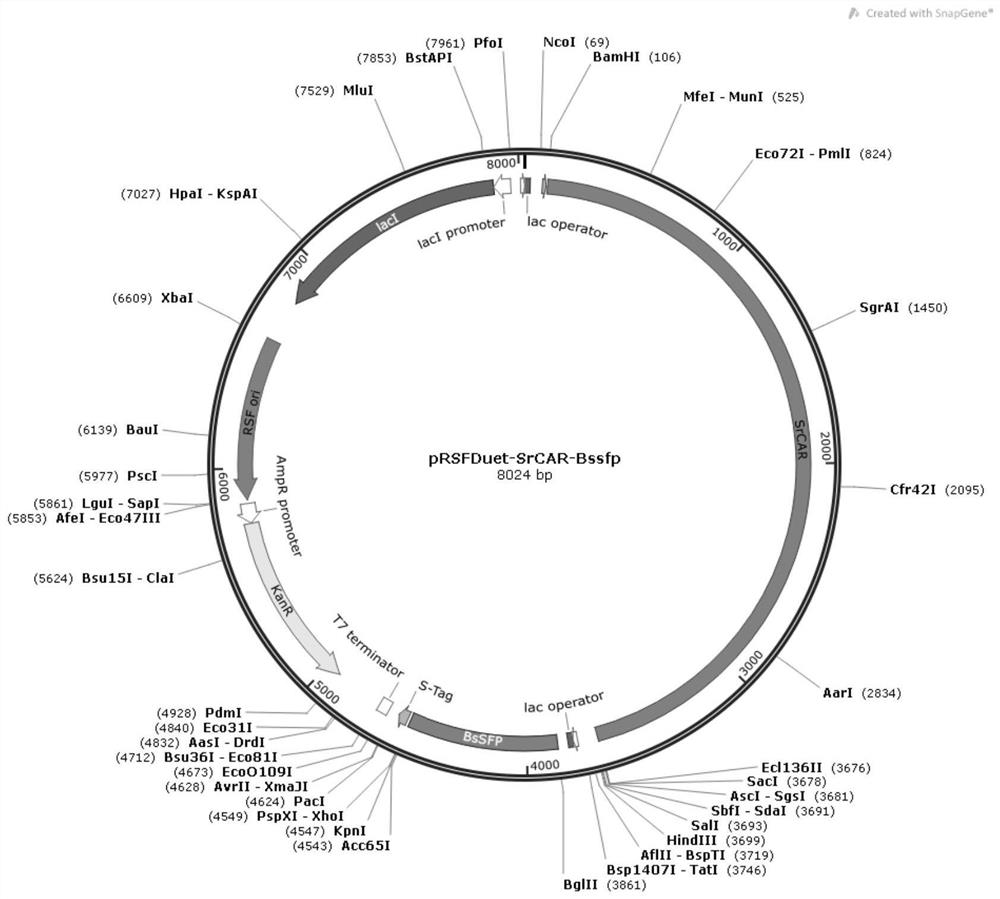

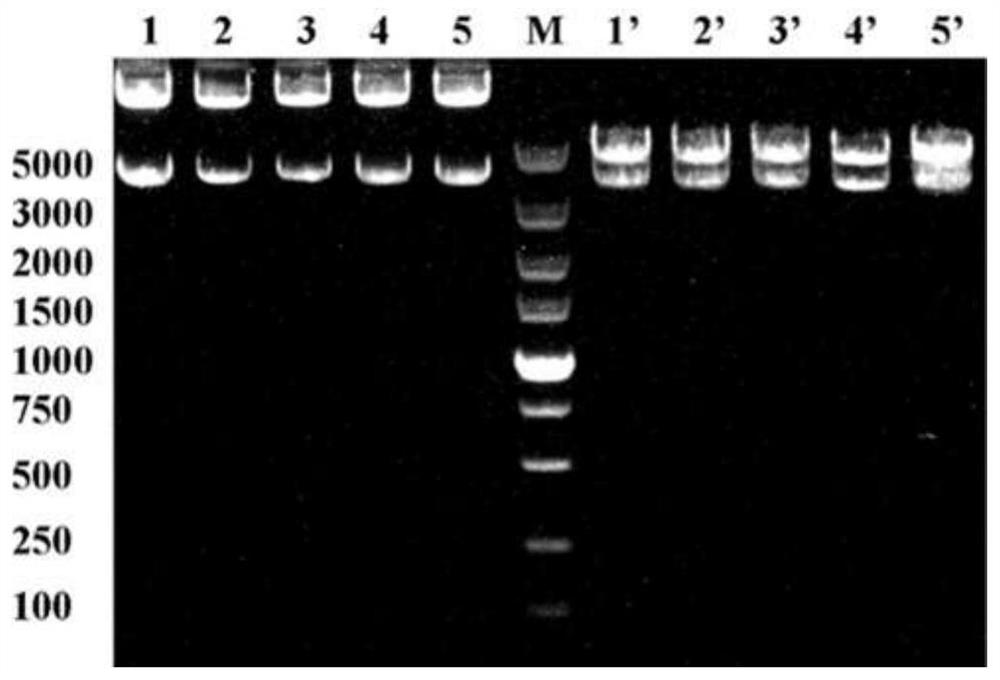

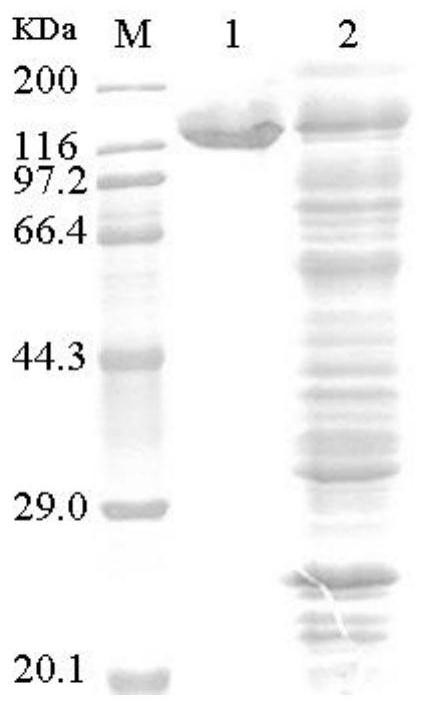

Carboxylic acid reductase recombinant plasmid as well as construction method and application thereof

The invention discloses a carboxylic acid reductase recombinant plasmid. The recombinant plasmid is obtained by connecting a carboxylic acid reductase gene and aphosphopantetheinyl transferase gene to a pRSFDuet-1 carrier. The invention further provides recombinant bacteria containing the recombinant plasmid, and carboxylic acid reductase SrCAR is further produced by using the recombinant bacteria and is applied to production of 1,2-propylene glycol. According to the present invention, the efficient synthesis approach of the biological preparation of 1,2-propylene glycol is achieved, the application prospect is high, the 1,2-propylene glycol is produced by using the carboxylic acid reductase SrCAR to catalyze glucose, and the yield of 1,2-propylene glycol within 4 h under the condition that the gene of the escherichia coli strain is not knocked out is 4-5 times of the yield of 1,2-propylene glycol synthesized by using a gene knockout escherichia coli strain containing a carboxylic acid reductase MavCAR in literature reports.

Owner:NANJING FORESTRY UNIV

A method for synthesizing fatty alcohol acetate in microorganisms

ActiveCN105331647BFast growthGenetic manipulation technology is matureBiofuelsMicroorganism based processesMicrobial transformationFatty alcohol

The invention discloses a method for synthesizing pheromone fatty alcohol acetate in microorganisms based on three intermediate products of fatty acid metabolism pathway as precursor molecules. The reductase CAR, fatty acyl-CoA reductase FAR and aldehyde reductase AHR are used to obtain engineering bacteria that can reduce fatty acyl-ACP, fatty acid or fatty acyl-CoA to produce fatty alcohol, respectively. Finally, alcohol acetyltransferase ATF1 was highly expressed in fatty alcohol-producing engineering bacteria, which was used to catalyze the reaction of fatty alcohol and acetyl-CoA to synthesize pheromone fatty alcohol acetate. The invention can realize the microbial transformation from glucose to fatty alcohol acetate, and provides a feasible way for large-scale biosynthesis of fatty alcohol acetate.

Owner:GANNAN NORMAL UNIV

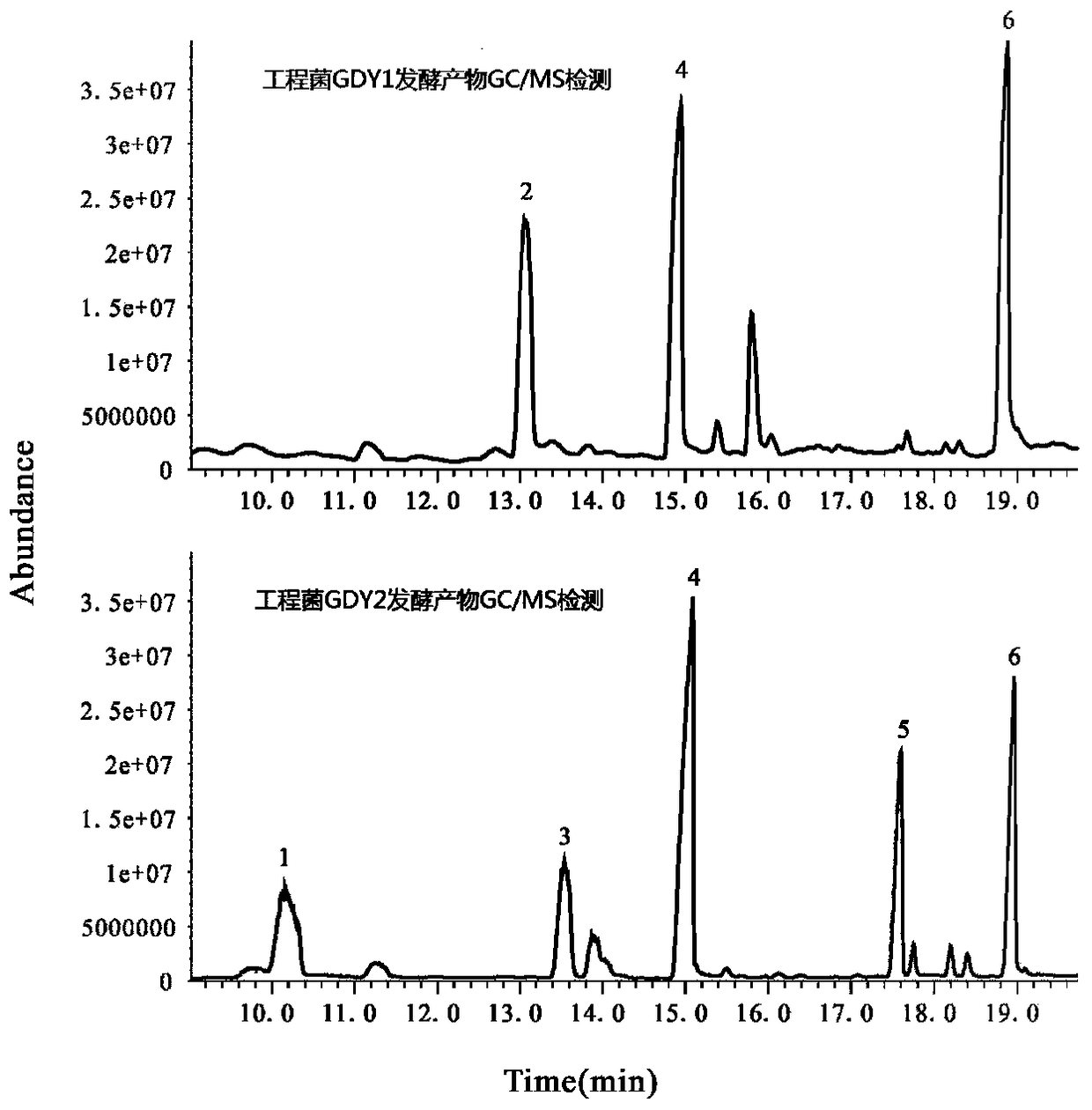

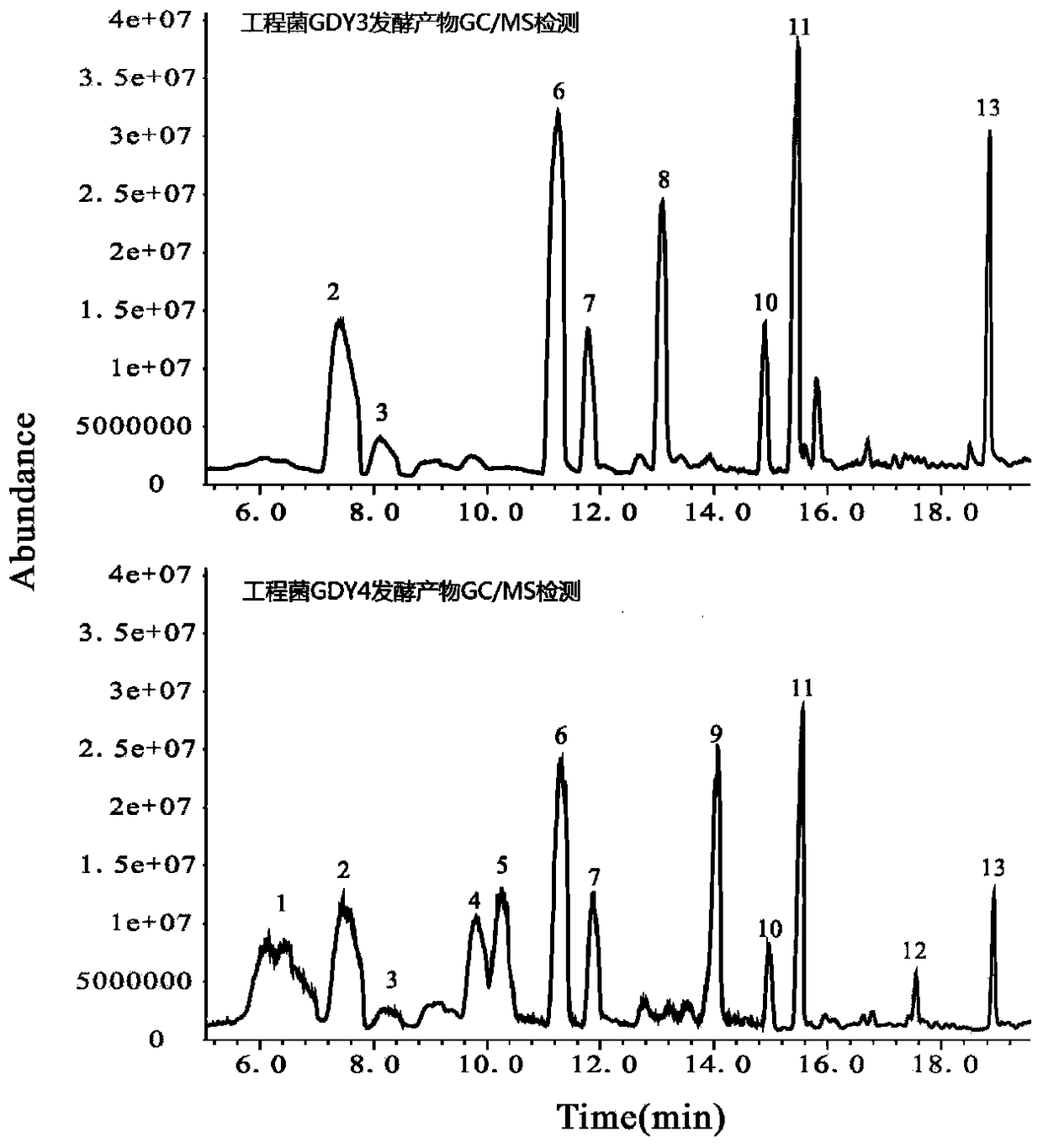

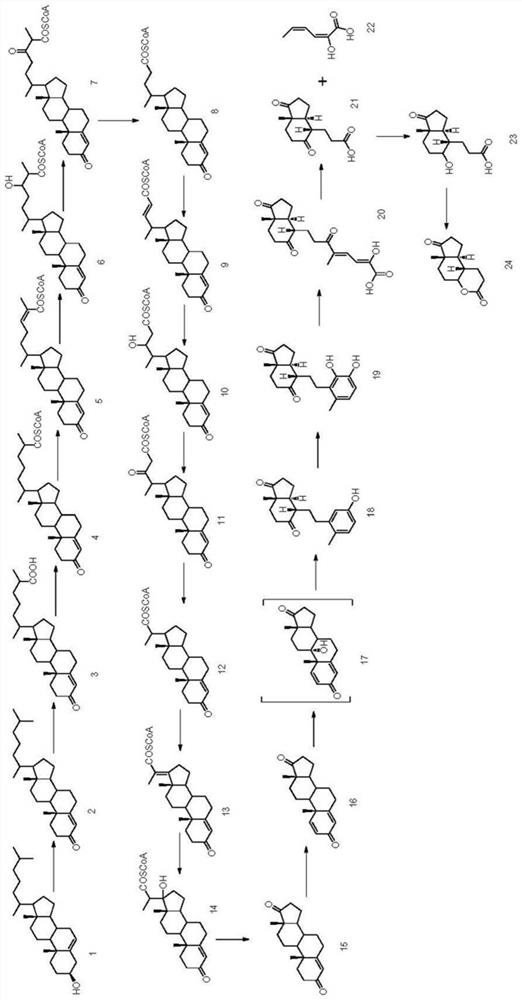

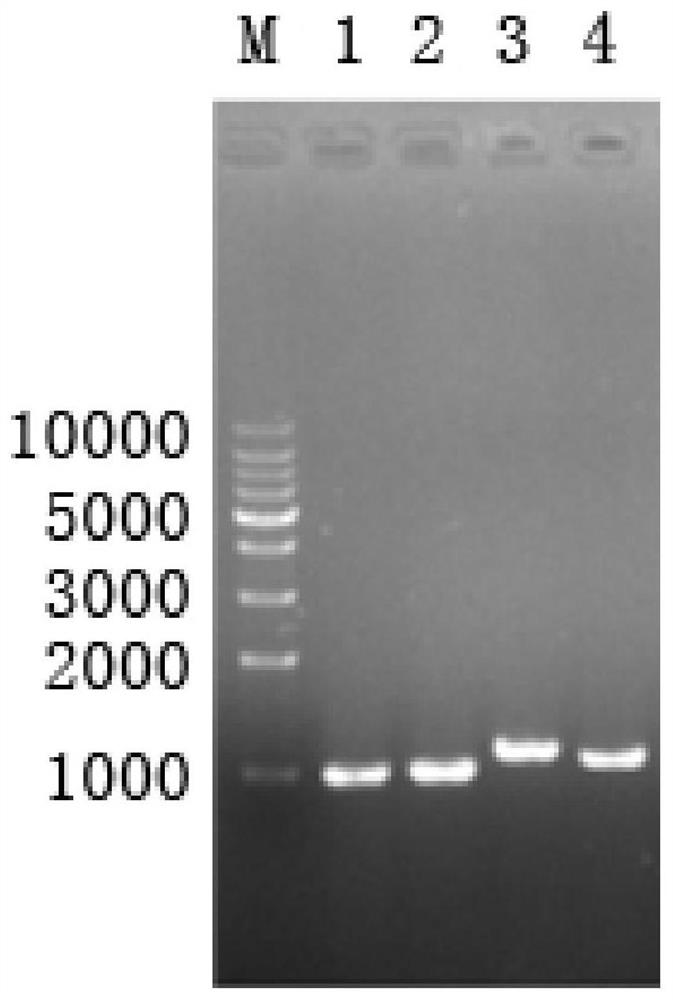

Method, engineering bacteria and application of microbial fermentative production of glutaractone

ActiveCN109722455BHigh substrate conversion rateInhibitory activityBacteriaMicroorganism based processesCarboxylic acid reductaseChemical compound

The invention provides a method for producing glutaractone through microbial fermentation, an engineering bacterium for producing glutaractone and application thereof. The method for producing glutaractone by microbial fermentation comprises utilizing glutaractone-producing bacteria to produce glutaractone by sterol fermentation, it is characterized in that, the described glutaractone-producing bacteria has at least one fatty acid coenzyme A / carboxylic acid reductase, and this enzyme can catalyze The reaction i of the following compounds I to II, and the method includes inhibiting the activity and / or expression of at least one of the fatty acid coenzyme A / carboxylate reductase in the glutaractone-producing bacteria, the reaction is: wherein , "-X" is hydroxyl or carbonyl; "-Y" is hydroxyl or "-SCoA". The invention can improve the conversion rate of the substrate during the fermentative production of glutaractone, reduce or block the generation of by-products, make the products easy to separate and purify, and reduce the production cost.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI +1

Variant dihydropicolinic acid reductase polypeptides and method for producing L-threonine using same

PendingCN114729338AIncrease productionReduce productionCarbon-nitrogen lyasesMicroorganism based processesCarboxylic acid reductaseDihydropyridine

Owner:CJ CHEILJEDANG CORP

Method for Producing Aldehyde

ActiveUS20190249207A1Reduce purification costsSelective generationTransferasesOxidoreductasesCarboxylic acid reductaseMicroorganism

A method is described for producing an objective substance, for example, an aldehyde such as vanillin. The objective substance is produced from a carbon source or a precursor of the objective substance by using a microorganism having an ability to produce the objective substance, wherein the microorganism has been modified to have a specific carboxylic acid reductase (CAR) gene, such as a Gordonia CAR gene, Novosphingobium CAR gene, or Coccomyxa CAR gene.

Owner:AJINOMOTO CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com