Genetically engineered bacterium for synthesizing vanillin and application of genetically engineered bacterium

A technology of genetically engineered bacteria and vanillin, applied in the fields of gene recombination and whole-cell catalysis, to achieve the effects of increasing production, strengthening industrialization potential, and realizing large-scale green and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] In order to construct a genetically engineered bacteria that can more efficiently convert vanillic acid to produce natural vanillin and optimize the regulation of the whole-cell catalytic process.

[0041] For this reason, the genetically engineered bacteria for the synthesis of vanillin involved in the first aspect of the present invention includes the following approach for synthesizing natural vanillin from vanillic acid: Catalyzed to generate natural vanillin, such as Figure 9 shown.

[0042] In order to realize the above-mentioned approach of synthesizing natural vanillin, the inventor constructed a genetically engineered bacterium for synthesizing vanillin by the following method:

[0043] Based on the operation means of genetic engineering, the present inventors arranged and combined Car and Sfp derived from various species, screened and obtained a more suitable combination of Car and Sfp with high efficiency, and passed substrate / product tolerance The engineeri...

Embodiment 1

[0066] In some specific embodiments of the present invention, the above-mentioned genetically engineered bacteria that use vanillic acid as a substrate to produce vanillin are constructed, and the engineered strain is used to catalyze the production of vanillin by whole cells. The reaction principle is as follows: Figure 9 As shown, it includes the following steps:

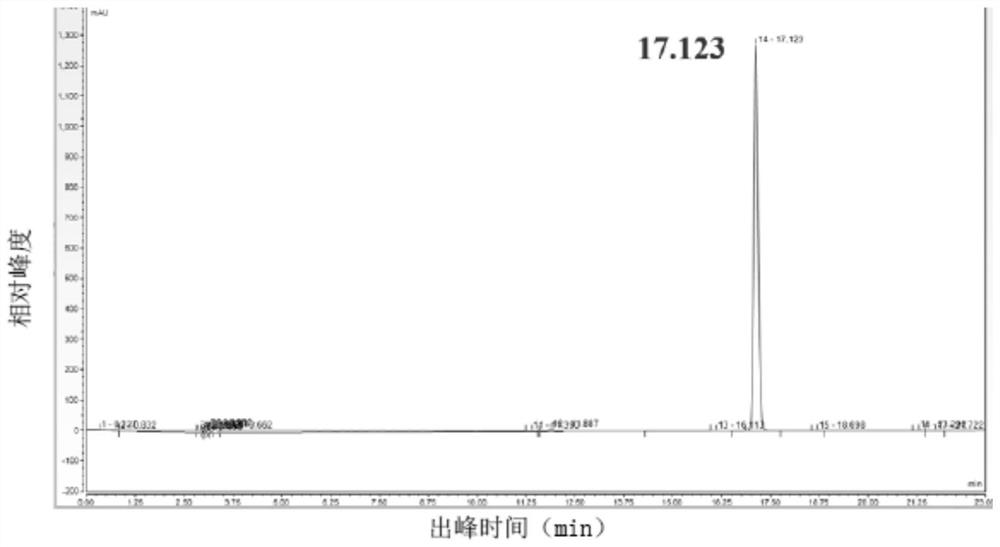

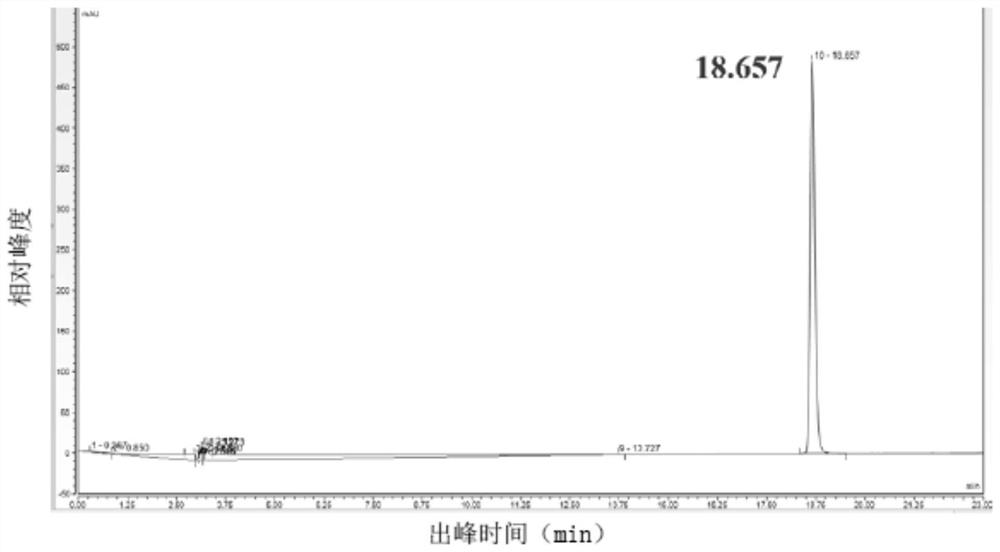

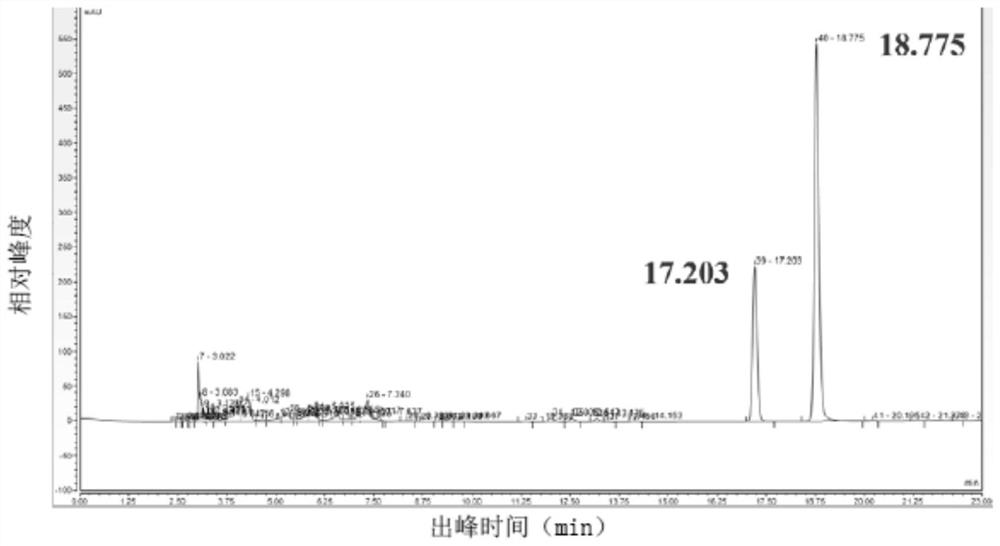

[0067] (1) Construction of overexpressed carboxylic acid reductase gene Car of multiple different species origins and phosphopantetheinyl transferase gene Sfp recombinant plasmids and recombinant strains derived from multiple different species, wherein SEQ ID No.1- 10 is described as an example, but the scope of protection of carboxylic acid reductase (Car) and phosphopantetheine transferase (Sfp) is not limited to the above species sources:

[0068]1. Use C(N)+S(N)-CF and C(N)+S(N)-CR in Table 1 as upstream and downstream primers, and use the sequence of SEQ ID NO.6 synthesized by the company as a template to am...

Embodiment 2

[0090] Embodiment 2: the formula of culture medium

[0091] The formula of the seed medium includes: yeast powder 5.0g / L, sodium chloride 5.0g / L, peptone 10.0g / L;

[0092] The formula of the fermentation medium includes (LB): yeast powder 5.0g / L, sodium chloride 5.0g / L, peptone 10.0g / L, glucose 20.0g / L;

[0093] The formula of the fermentation medium includes (M9): glycerol 10.0g / L, glucose 3.0g / L, M9 Minimal Salt (5×) 11.28g / L, yeast powder 5.0g / L, MOPS 2.0g / L;

[0094] The formula of the fermentation medium in the upper tank includes glycerol 20.0g / L, glucose 10.0g / L, M9 Minimal Salt (5×) 11.28g / L, yeast powder 5.0g / L, 0.05mM CaCl 2 , 0.5mM MgSO 4 , trace elements (100×): EDTA5 g / L, FeCl 3 .6H2O 0.83g / L, ZnCl 2 0.084 g / L, CuCl 2 .2H 2 O 0.013g / L, CoCl 2 .2H 2 O 0.01g / L, H 3 BO 3 0.01 g / L, MnCl 2 .4H 2 O 0.0016g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com