Homo-polypropylene beta nucleating agent and preparation method thereof

A technology of homopolypropylene and crystal nucleating agent, which is applied in the field of polypropylene, can solve the problems of affecting production efficiency, thermodynamic instability, inability to apply and popularize, etc., and achieve the effect of improving toughness and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

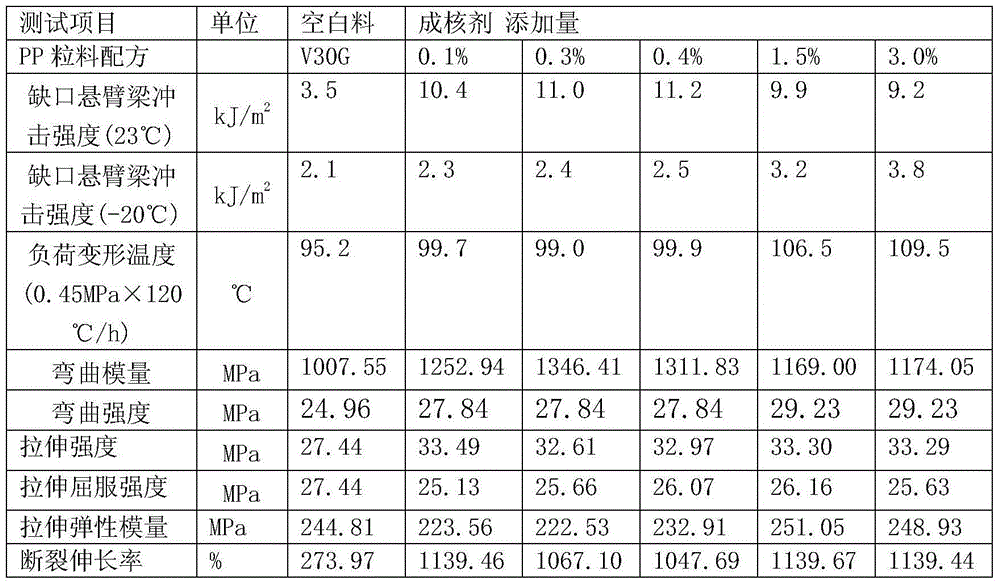

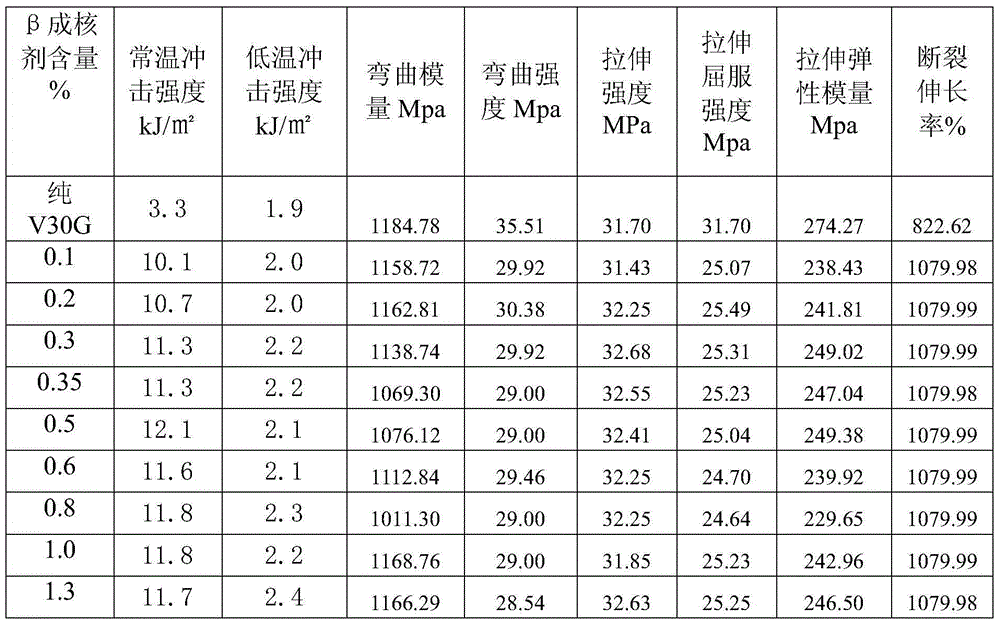

Examples

Embodiment 1

[0027] The homopolypropylene β-crystal nucleating agent described in the present invention, calculated according to mass percentage, includes the following components:

[0028] 0.8% high-efficiency β-crystal nucleating agent, 3% acid absorbing agent, 2.5% attachment agent, 43.7% rigid particle, and 50% synergist.

[0029] Among them, the high-efficiency β-crystal nucleating agent is calcium pimelate and zinc salt, the acid absorbing agent is calcium salt of fatty acid, the attachment agent is fatty acid, the rigid particle is silicon dioxide, and the synergist is calcium carbonate. At the same time, the fatty acid~~salt can also act as a dispersant and a stabilizer, the fatty acid can also act as a dispersant, and the silicon dioxide can act as a β crystal nucleating agent.

[0030] The preparation method of the homopolypropylene β-crystal form nucleating agent described in the present invention is to put the raw materials in the above ratio into a high-speed disperser and mix...

Embodiment 2

[0033] The only difference between this example and Example 1 is that the ratio of each component in the homopolypropylene β crystal nucleating agent has changed, specifically:

[0034] 2% high-efficiency β-crystal nucleating agent, 2% acid absorbing agent, 1.5% attachment agent, 28.5% rigid particles, and 66% synergist.

[0035] Among them, the high-efficiency β-crystal nucleating agent is pimelic acid calcium salt, the acid absorbing agent is fatty acid zinc salt, the attachment agent is fatty acid, the rigid particle is silicon dioxide, and the synergist is calcium carbonate. At the same time, the fatty acid zinc salt can also act as a dispersant and a stabilizer, the fatty acid can also act as a dispersant, and silicon dioxide can act as a β crystal nucleating agent.

Embodiment 3

[0037] The only difference between this example and Example 1 is that the ratio of each component in the homopolypropylene β crystal nucleating agent has changed, specifically:

[0038] 0.1% high-efficiency β-crystal nucleating agent, 5% acid absorbing agent, 1% attachment agent, 75% rigid particles, and 18.9% synergist.

[0039] Among them, the high-efficiency β-crystal nucleating agent is pimelic acid zinc salt, the acid absorbing agent is fatty acid zinc salt, the attachment agent is fatty acid, the rigid particle is silicon dioxide, and the synergist is calcium carbonate. At the same time, the fatty acid zinc salt can also act as a dispersant and a stabilizer, the fatty acid can also act as a dispersant, and silicon dioxide can act as a β crystal nucleating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com