Unsaturated polyester with low viscosity and application thereof

An unsaturated, low-viscosity technology, used in organic dyes, dyeing physical treatment, pigment slurry, etc., can solve the problems of shortened processing time, difficult to widely use, difficult to paste pigments, etc., to facilitate production operations, reduce production costs, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 low viscosity unsaturated polyester

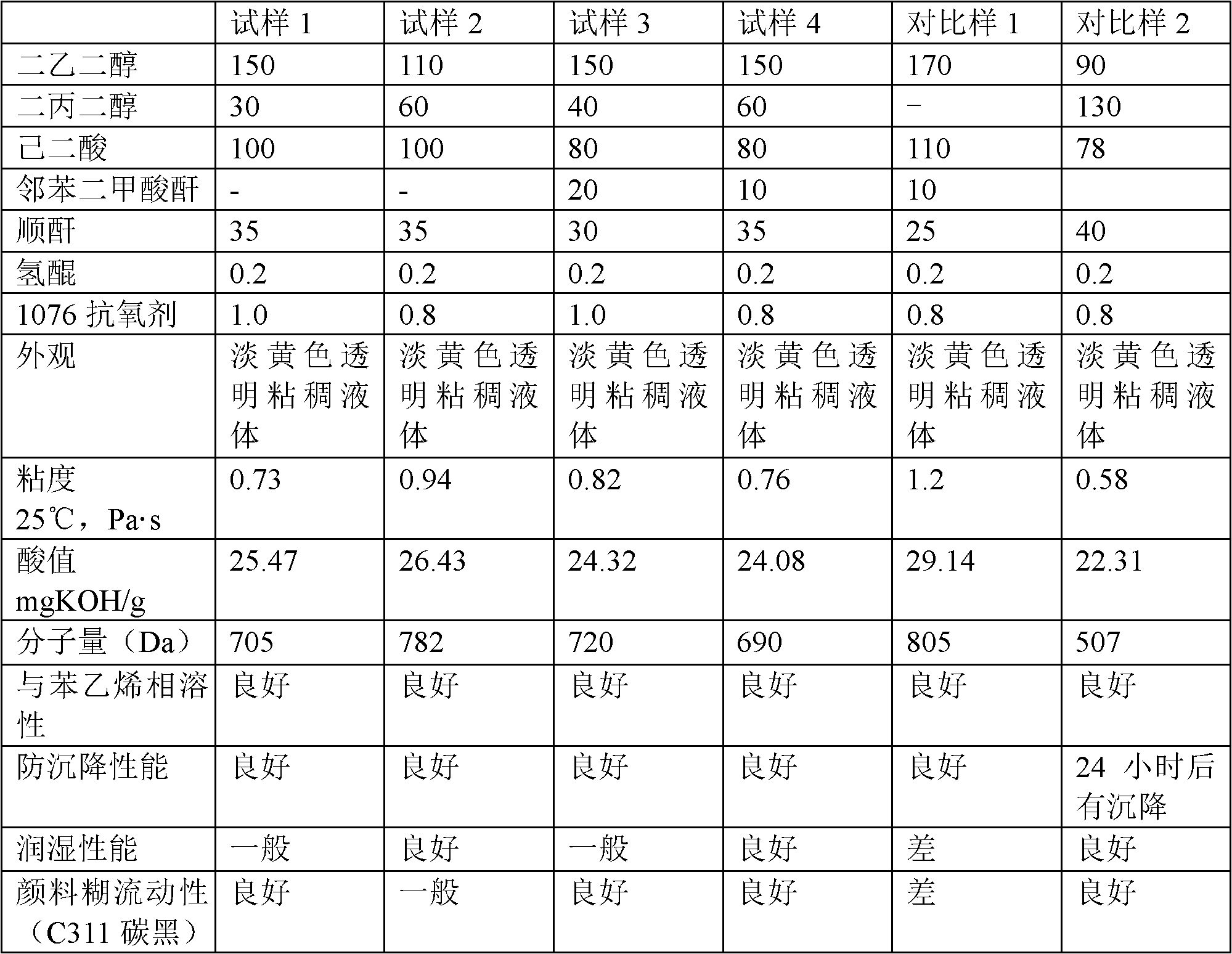

[0034] Weigh each component as listed in Table 1, and prepare various unsaturated polyesters according to the usual method for unsaturated polyesters, and measure the appearance, acid value, viscosity and molecular weight of the obtained polyesters. The amounts of the respective monomers in Table 1 are parts by weight.

[0035] It can be seen from Table 1 that dipropylene glycol is a key material to improve the wetting performance of polyester and pigment powder. With the increase of the amount of dipropylene glycol used, the wetting performance of polyester to pigment powder is also gradually improved; The ratio is the key factor determining the matching between the acid value and viscosity of the polyester. The higher the alkyd ratio is, the lower the acid value and viscosity of the polyester will be, and the molecular weight will decrease accordingly. The anti-sedimentation performance of the pigme...

Embodiment 2

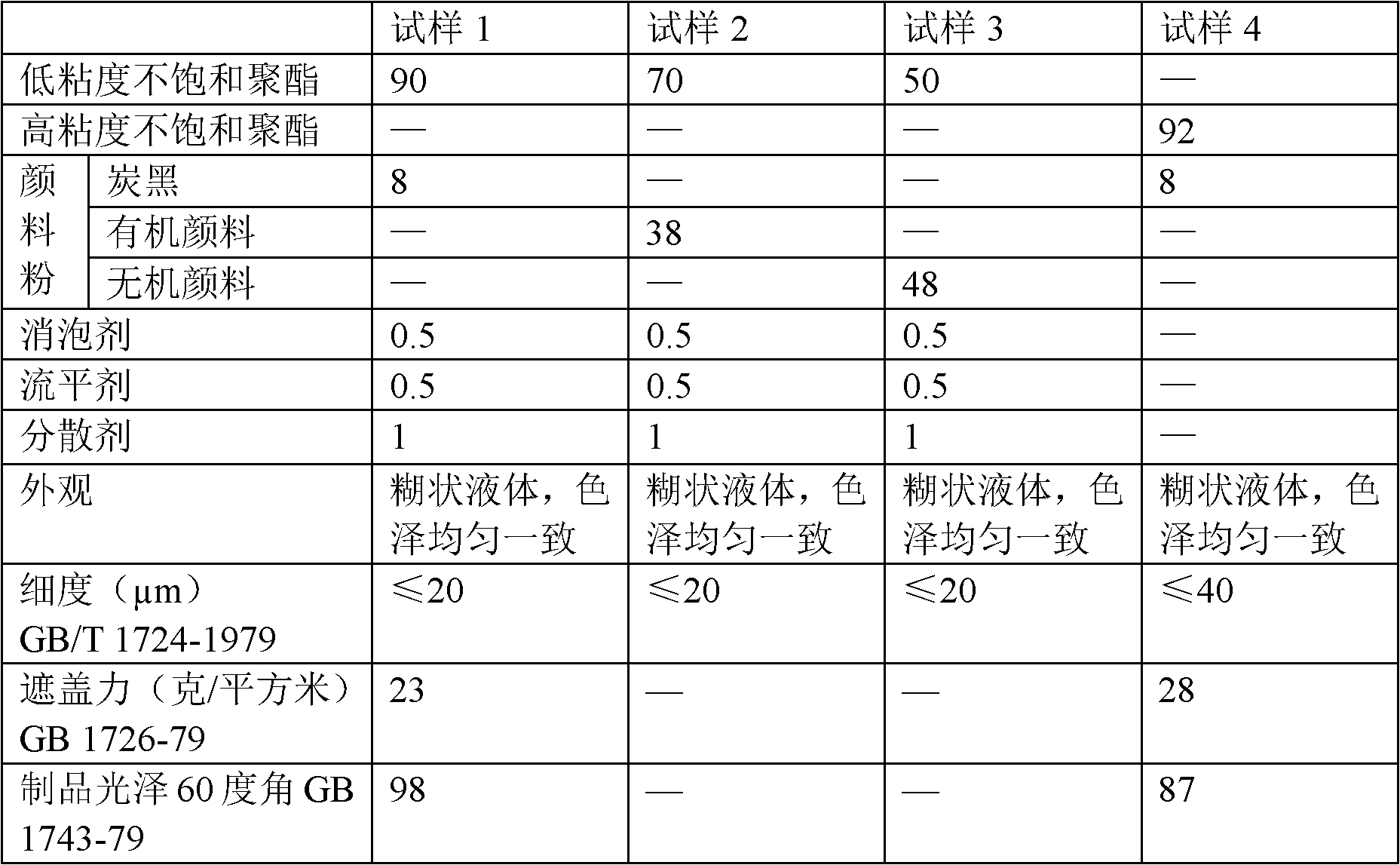

[0040] The preparation of embodiment 2 pigment paste

[0041] According to the materials listed in Table 2 and their consumption (by weight), various pigment pastes are made, and the preparation method is as follows:

[0042] (1) Stir low-viscosity unsaturated polyester with defoamer and dispersant evenly, then add carbon black pigment powder and disperse evenly at a speed of 400-600 rpm.

[0043] (2) Place the uniformly dispersed pigment paste for more than 12 hours, and use the sanding process for sanding production.

[0044] As can be seen from Table 2, compared with the prior art (embodiment 4), the viscosity of the original carrier resin used is high without any auxiliary agent, and low viscosity unsaturated polyester, dispersant, leveling agent and defoamer are adopted These components have made technological progress. The pigment paste prepared by the combination of low-viscosity unsaturated polyester, dispersant and defoamer has achieved better technical effect. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com