Beta-crystal PPR pipe fitting and production method thereof

A technology for pipe fittings and crystal nucleating agent, which is applied in the field of chemical building materials, can solve the problems of high viscosity molding of PPR pipe fittings, no antibacterial problem, no toughness problem, etc. The effect of loss and guarantee of hygienic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention proposes a preparation method of β-crystal PPR pipe fittings. The materials used include: PPR resin, β-crystal nucleating agent, nanometer material, flow modifier, antibacterial agent, antioxidant, and color masterbatch. The β-crystal nucleating agent is one of calcium stearate / pimelic acid, aromatic amides or rare earths or a compound thereof. The nano-inorganic powder is one of nano-calcium carbonate or zinc oxide or a composite thereof. The flow modifier is one or more mixtures of the following substances: polyethylene wax, paraffin wax, polypropylene wax, oxidized polyethylene wax, montan ester wax, calcium stearate, zinc stearate, silicone A type of lubricant and a fluorine-containing lubricant, a silicone resin or a fluorine-containing rheological agent or a combination thereof. The antibacterial agent is based on zeolite as a carrier, and the antibacterial component is metal ion Ag + or Zn 2+ . The antioxidant is a main and auxiliary antioxidant...

Embodiment 1

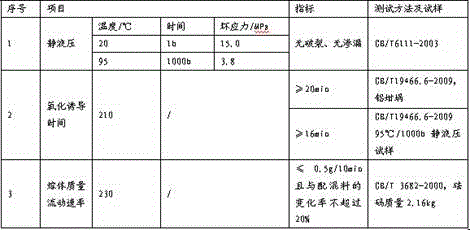

[0025] 100 parts of PPR resin, 0.3 part of calcium stearate / pimelic acid, 0.1 part of silver antibacterial agent, 2 parts of nano-calcium carbonate, 0.25 part of silicone lubricant, 0.05 part of antioxidant 1010, 0.05 part of antioxidant 168 parts, 6 parts of white mother. Stir for 5 minutes with a high-speed mixer, and then use an extruder to form a pipe. The properties of the pipe are shown in Table 1.

Embodiment 2

[0027] 100 parts of PPR resin, 0.1 part of aromatic amide and rare earth nucleating agent, 0.3 part of zinc antibacterial agent, 1 part of nano calcium carbonate, 0.3 part of fluoroelastomer, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 6 copies of gray mother. Stir for 5 minutes with a high-speed mixer, and then use an extruder to form a pipe. The properties of the pipe are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com