Short-process low-temperature dyeing aid and preparation method thereof

A low-temperature dyeing and short-process technology, which is applied in the fields of dyeing, textiles and papermaking, can solve the problems of long process and achieve the effects of improving production efficiency, reducing dyeing temperature and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

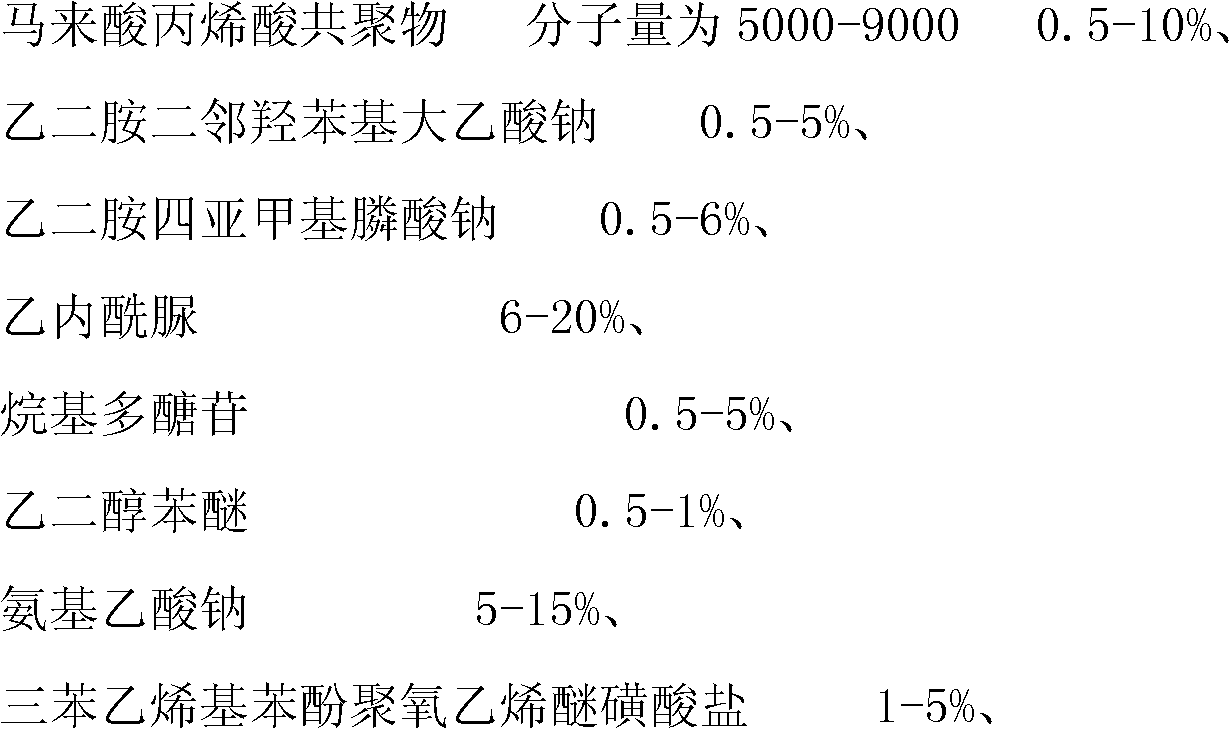

[0014] The composition of a short-process low-temperature dyeing auxiliaries of the present invention is by weight percentage:

[0015]

[0016] The preparation method of this dyeing auxiliary: First add the pure water of the whole formula into the emulsification disperser equipped with a stainless steel agitator, then start the equipment, and mix each component with maleic acid acrylic acid copolymer, ethylenediamine di-ortho-hydroxy Sodium phenyl macroacetate, sodium ethylenediamine tetramethylene phosphonate, hydantoin, alkyl polyglucoside, ethylene glycol phenyl ether, sodium glycine, tristyrylphenol polyoxyethylene ether sulfonate, Secondary alcohol polyoxyethylene ether, benzyl benzoate, and pure water are added sequentially. After adding all the components, continue to emulsify and disperse for 0.5-2 hours. Stop stirring when the solution becomes transparent and light brown, and the processing is completed.

Embodiment 2

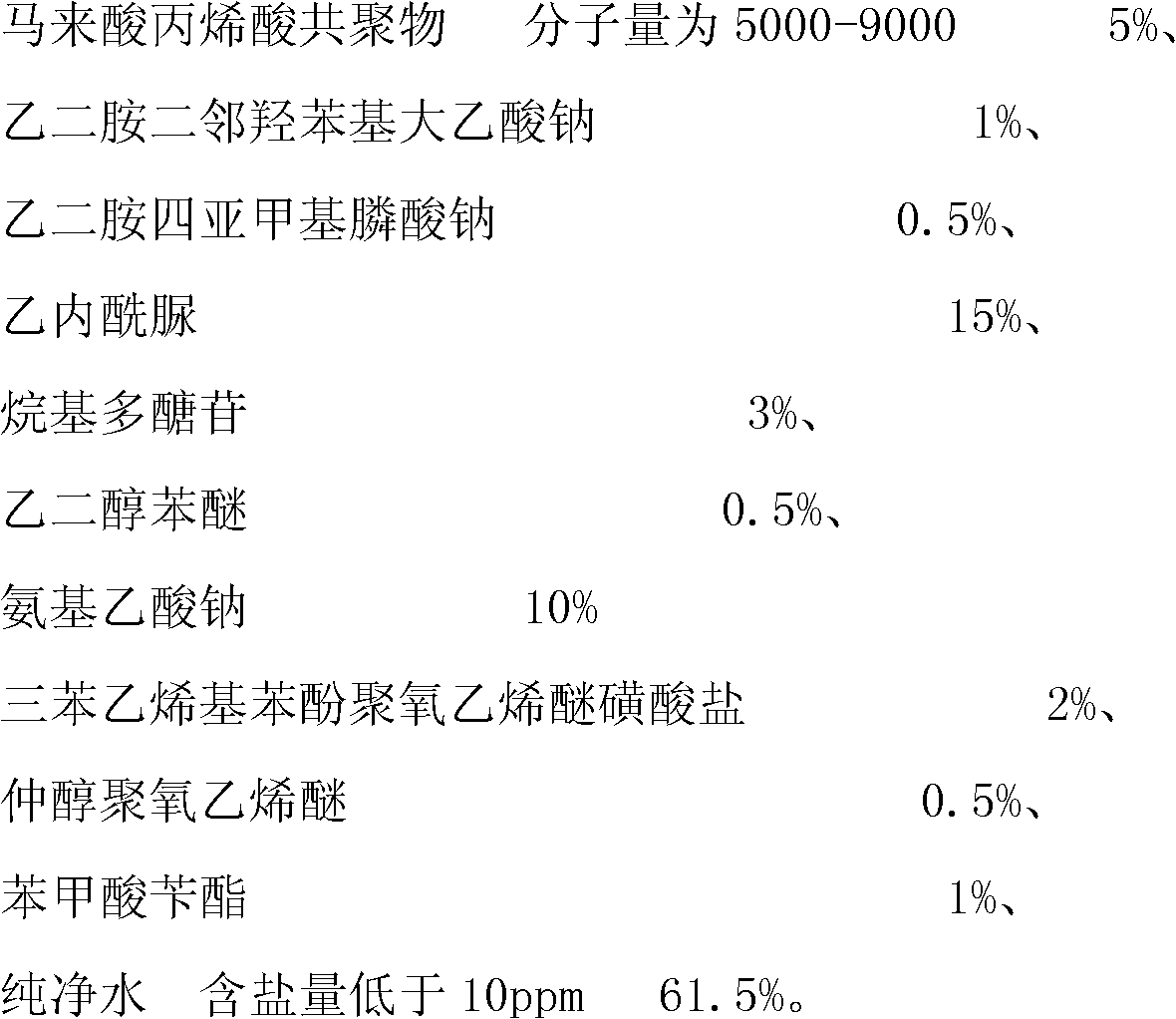

[0018] The composition of a short-process low-temperature dyeing auxiliaries of the present invention is by weight percentage:

[0019]

[0020] The preparation method of this dyeing auxiliary is with embodiment 1.

[0021] Taking polyester knitted fabrics as an example, the polyester knitted gray fabric is directly put into the vat for dyeing without pre-treatment and degreasing, and the short-process low-temperature dyeing auxiliary 1.5-3g / l in the embodiment 1 or embodiment 2 of the present invention is first added, and then Add disperse dyes and control the temperature rise rate at 0.6-1°C / min from 60°C, directly raise the temperature to 120-125°C and keep it for 20-50 minutes, then lower the temperature to 75°C at a cooling rate of 1-2°C / min Afterwards, drain and wash with water. After dyeing, the medium and light colors can be washed with water for 1-2 times, and the dark colors need to be washed with hot water above 80°C once, and then washed with cold water to be re...

Embodiment 3

[0025] The composition of a short-process low-temperature dyeing auxiliaries of the present invention is by weight percentage:

[0026]

[0027] The preparation method of this dyeing auxiliary: First add the pure water of the whole formula into the emulsification disperser equipped with a stainless steel agitator, then start the equipment, and mix each component with maleic acid acrylic acid copolymer, ethylenediamine di-ortho-hydroxy Sodium phenyl macroacetate, sodium ethylenediamine tetramethylene phosphonate, hydantoin, alkyl polyglucoside, ethylene glycol phenyl ether, sodium glycine, tristyrylphenol polyoxyethylene ether sulfonate, Benzyl benzoate and pure water components are added sequentially, after adding all the components, continue to emulsify and disperse for 0.5-2 hours, stop stirring when the solution becomes transparent and light brown, and the processing is completed.

[0028] Take the polyester / viscose blended woven fabric as an example, the polyester / visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com