Complete complex fertilizer and production method thereof

A complexing fertilizer and complexing technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of not being able to utilize the effective nutrients of fertilizers to the greatest extent, and easy loss of fertilizers, so as to achieve thorough absorption of crops, diversification of use methods, highly absorbable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

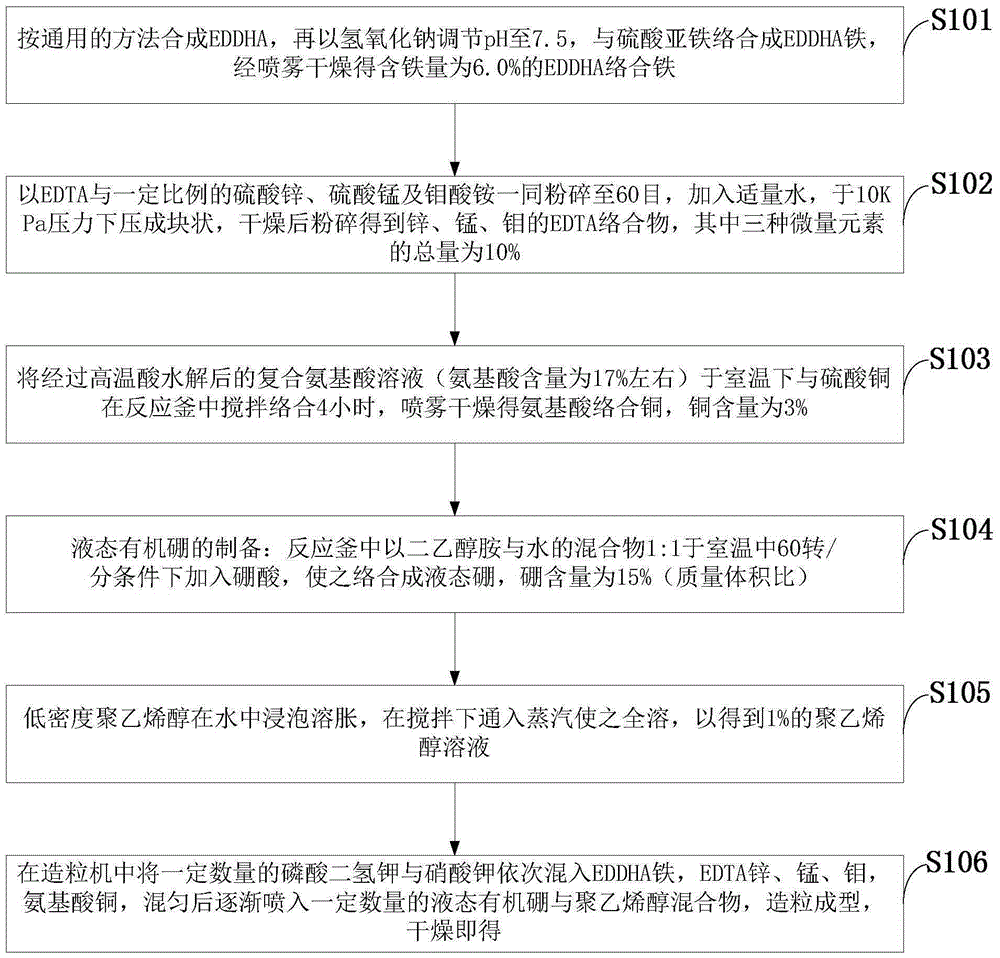

Method used

Image

Examples

Embodiment 1

[0031] Get 60 parts of potassium nitrate and add 30 parts of potassium dihydrogen phosphate, mix in successively 2 parts of EDDHA complexed iron, 2 parts of EDTA zinc, manganese and molybdenum, 2 parts of amino acid complexed copper, After mixing, place it in a drum granulator, and at 30 rpm, spray a mixture consisting of 2 parts of the prepared liquid boron and 2 parts of the prepared polyvinyl alcohol solution to make it into 2 parts -3mm granular, then dry at 95°C.

Embodiment 2

[0033] Get 60 parts of potassium dihydrogen phosphate and add 30 parts of potassium nitrate, mix in successively 2 parts of EDDHA complexed iron, 2 parts of EDTA zinc, manganese and molybdenum, 2 parts of amino acid complexed copper, After mixing evenly, place it in a drum granulator, and at 30 rpm, spray a mixed solution consisting of 2 parts of the prepared liquid boron and 2 parts of the prepared polyvinyl alcohol to form a 2- The granular shape of about 3mm can be dried at 95°C.

Embodiment 3

[0035] Get 45 parts of potassium dihydrogen phosphate and 45 parts of potassium nitrate, mix in successively 4 parts of EDDHA complexed iron, 2 parts of EDTA zinc, manganese and molybdenum, 1 part of amino acid complexed copper, After mixing evenly, place it in a drum granulator, and at 30 rpm, spray a mixture of 2 parts of the prepared liquid boron and 1 part of the prepared polyvinyl alcohol to form a 2- The granular shape of about 3mm can be dried at 95°C.

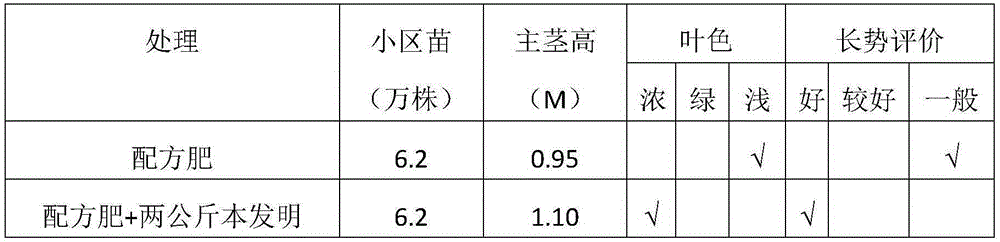

[0036] The application effects of the present invention will be described in detail below in conjunction with specific tests.

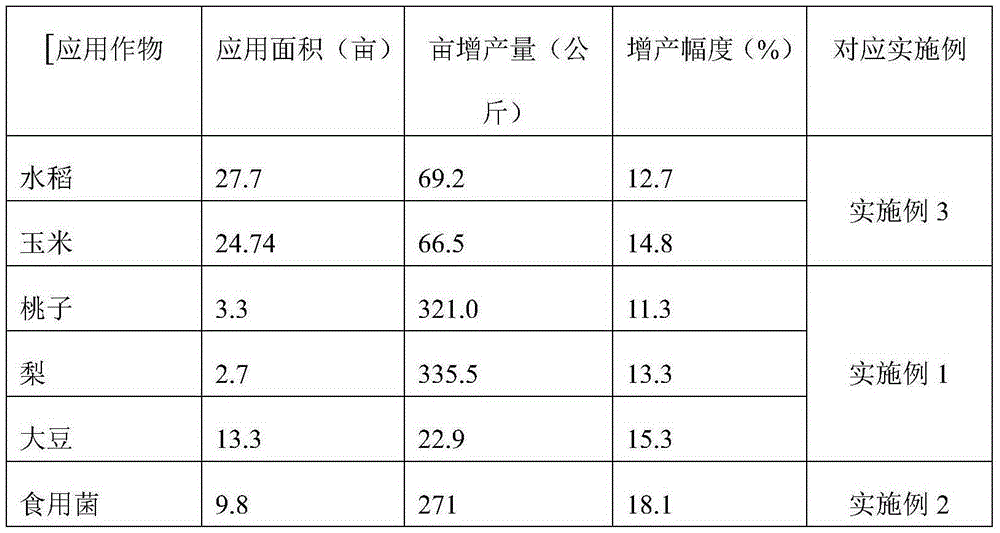

[0037] Through the field test, when the present invention mixes water 300 times and carries out topdressing once in the mode of irrigation or spraying, the production increase data is as follows:

[0038]

[0039] The invention utilizes the available nutrients in the fertilizer to the greatest extent. The invention has comprehensive nutrients, including a large number of elements and meridia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com