A surface anti-corrosion layer coating device for marine iron outfitting processing

A technology of coating device and iron outfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

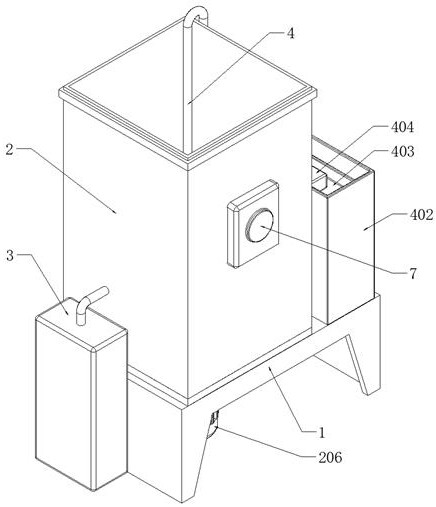

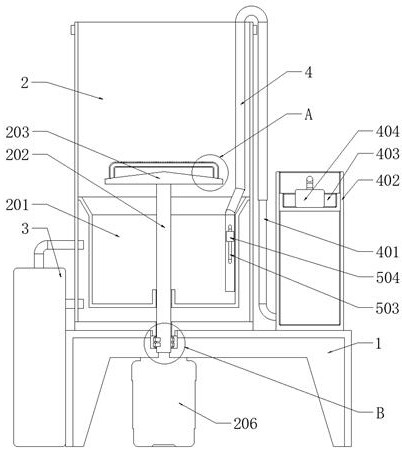

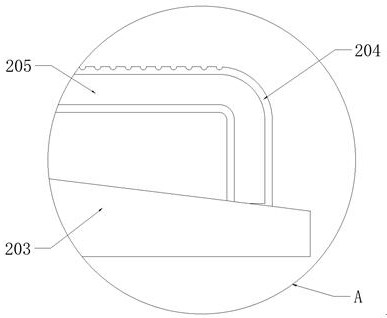

[0045] see Figure 1-2 and Figure 6 , a surface anti-corrosion layer coating device for marine iron outfitting, including a base 1, a main box 2 is fixedly installed on the top of the base 1, and a dipping box 201 is slidingly connected to the inside of the main box 2, and the dipping box 201 The outer dimensions are compatible with the internal dimensions of the main box body 2, and the inside of the main box body 2 is rotatably connected with a main shaft 202 that runs through the inside of the dipping box 201, and the top of the main shaft 202 is fixedly welded with a horizontally arranged placement platform 203, and the placement platform 203 The position of the top edge of the platform is set as a downward sloping structure, and the top of the placing table 203 is evenly fixed with a plurality of brackets 204 .

[0046] When the device is working, since the placing table 203 will be immersed in the anti-corrosion coating inside the dipping box 201 as the dipping box 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com