Liquid phase load type gas desulfurizing agent

A desulfurizer and load-type technology, which is applied in the field of chemical product preparation, can solve the problems of large investment in equipment, high total operating cost and high energy consumption, and achieve the effects of good desulfurization effect, energy saving and operating cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

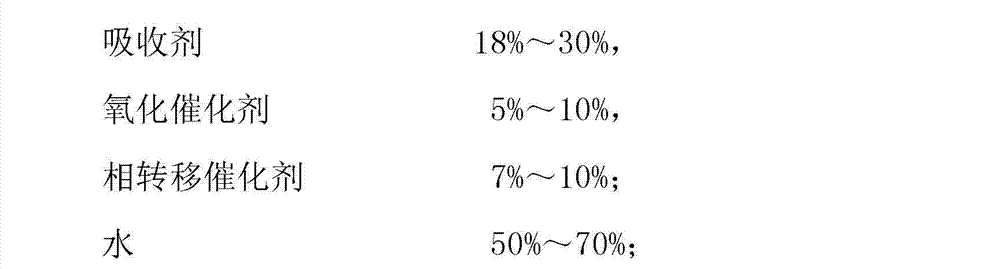

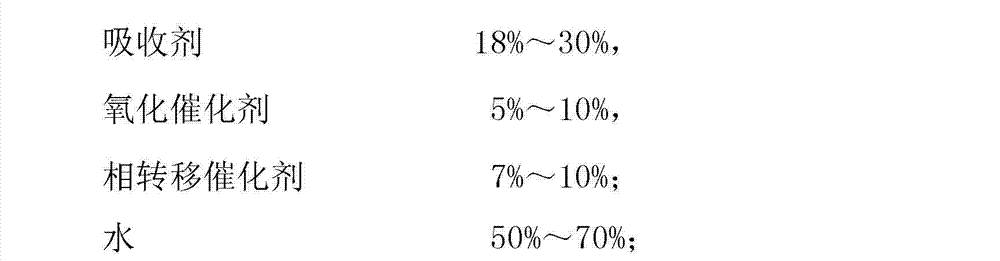

Method used

Image

Examples

Embodiment 1

[0019] Sodium carbonate, EDTA iron, sulfonated anthraquinone, octylamine, and water are mixed in a mass ratio of 9:1.2:0.8:4:25 to prepare component A, and the component A is sprayed on the lignite active On the coke (component B), the mass ratio of the two (A, B) is 4:6. After it is completely absorbed, it becomes a high-efficiency desulfurizer and is loaded into the desulfurization tower. The gas to be purified is oilfield associated gas containing hydrogen sulfide 500ppm, the processing capacity is 6000 cubic meters per hour, the desulfurizer is filled with 5 cubic meters, at 40 ℃, the space velocity is 1200 per hour, the working sulfur capacity is 46.7%, and the outlet gas hydrogen sulfide ,20ppm.

[0020] The process conditions are as follows:

[0021] The oilfield associated gas contains macromolecular organic substances such as tar and benzene to prevent these substances from clogging the effective pore size of the desulfurizer. In the pretreatment part of the scheme, ...

Embodiment 2

[0023] Potassium carbonate, sodium carbonate, sodium bisulfite, EDDHA iron, cobalt phthalocyanine, tert-butylamine, and water are mixed in a mass ratio of 4:2:1.6:1.6:0.4:2.4:18 to prepare component A , spray component A on lignite activated coke (component B), the mass ratio of the two (A, B) is 3:7, after it is completely absorbed, it will be a high-efficiency desulfurizer, and it will be loaded into the desulfurization tower . The processing capacity is 8000 cubic meters per hour, the desulfurization agent is filled with 7 cubic meters, and the synthesis gas containing hydrogen sulfide 1700ppm to be purified is at 35°C, the space velocity is 1100-1200 / hour, the working sulfur capacity is 48.3%, and the outlet gas hydrogen sulfide is 30ppm .

[0024] Processing condition is the same as embodiment one.

Embodiment 3

[0026] Take sodium bicarbonate, sodium carbonate, EDDHA iron, sulfonated cobalt phthalocyanine, tert-butylamine, and water according to the mass ratio of 4:5.5:1.3:0.7:3.5:20 and mix together to prepare component A, and spray it On the semi-coke (component B), the mass ratio of the two (A, B) is 3.5:6.5. After it is completely absorbed, it becomes a high-efficiency desulfurizer and is loaded into a desulfurization tower. The gas to be purified is semi-coke furnace tail gas containing 1450ppm hydrogen sulfide, the treatment capacity is 8000 cubic meters per hour, the desulfurizer is filled with 7 cubic meters, at 45 °C, the space velocity is 3000 per hour, the working sulfur capacity is 42.7%, and the outlet gas is vulcanized Hydrogen 40ppm.

[0027] Processing condition is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com