Cleaning agent for engine circulating cooling system, and preparation method and cleaning method thereof

A circulating cooling and cleaning agent technology, which is applied in the cooling of engines, engine components, machines/engines, etc., can solve the problems of complex materials of engine circulating cooling pipelines, inability to effectively remove oil, rust, scale, and inconvenience, and achieve good cooling Corrosion and anti-corrosion function, increase the ability of anti-corrosion, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

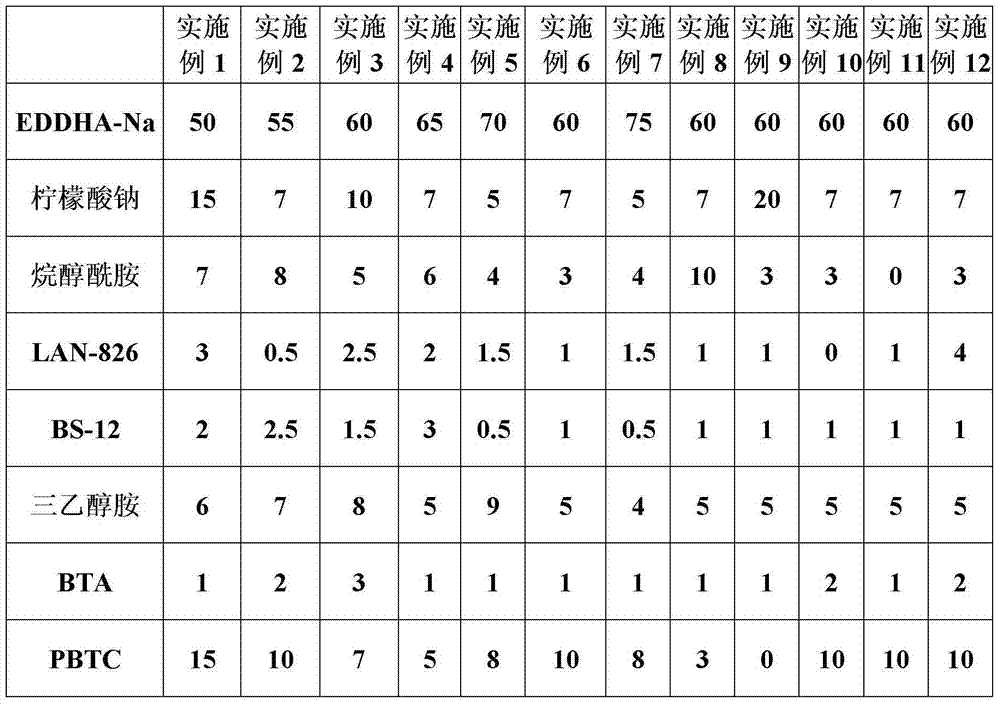

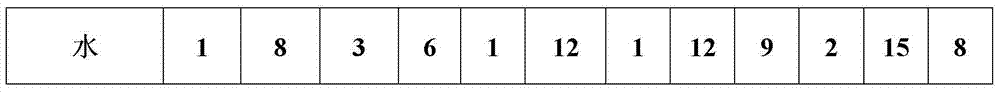

[0021] The present invention will be further described in detail below in combination with specific embodiments.

[0022] The inventors of the present application found that the combination of EDDHA-Na, sodium citrate and PBTC can effectively remove rust; the combination of EDDHA-Na, alkanolamide, BS-12 and triethanolamine can effectively remove oil stains and organic pollution The combination of alkanolamide, LAN-826, and BTA can effectively protect various metal materials and organic materials including carbon steel, stainless steel, copper alloy, aluminum alloy, etc. from corrosion. The inventor combined the above components together, and by reasonably setting the ratio of each component, made the cleaning agent of the present invention, which can effectively remove the pollution components such as rust, scale, oil stain and biofilm, and has certain influence on the surface material of the equipment. The protective effect does not affect the normal use of the material.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com