EDDHA chelated organic micro-fertilizer and preparation method thereof

An organic and micro-fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low energy consumption, poor crop pertinence, low effectiveness, etc., achieve low dosage and solve various crop deficiencies Symptoms, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

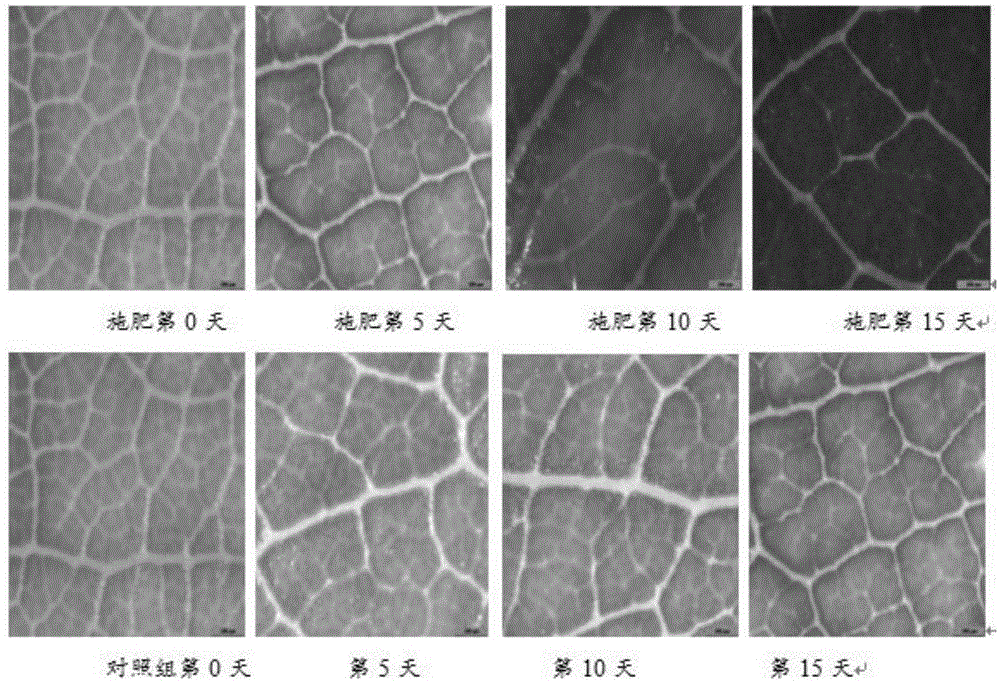

Image

Examples

Embodiment 1

[0026] Embodiment 1: the EDDHA chelated ternary compound micro-fertilizer of iron, zinc, manganese

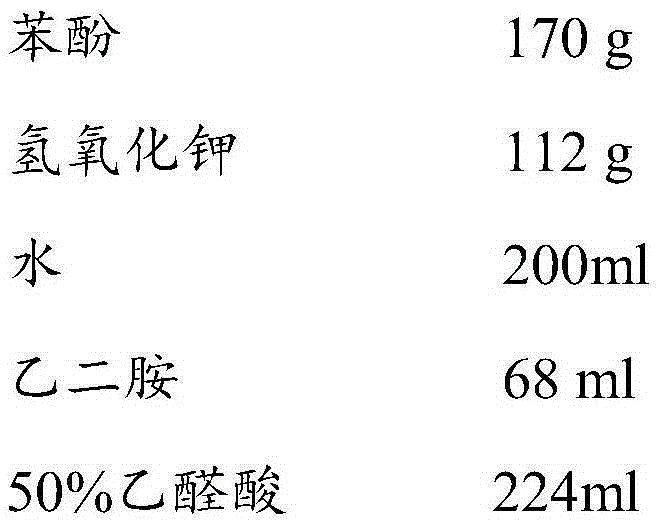

[0027] 1. Synthesis of EDDHA

[0028]

[0029] Put the above chemical reagents in a reaction kettle, heat to 65-75°C, and stir. Add ethylenediamine dropwise under stirring, then slowly add 50% glyoxylic acid dropwise, and keep it for 1~2h.

[0030] 2. Preparation of trace element ion solution

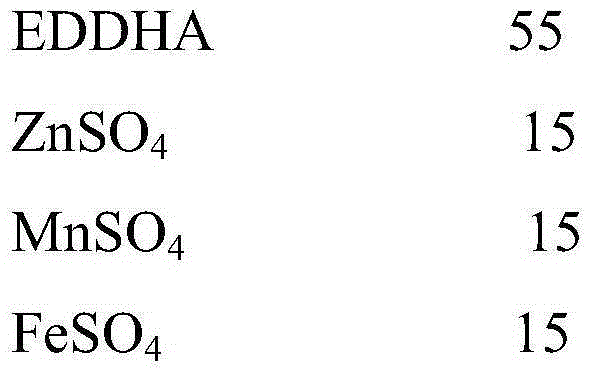

[0031] The molar ratio of ingredients is

[0035] At room temperature, the above solid powders were dissolved in 100ml of water respectively, and stirred until completely dissolved.

[0036] 3. Chelate preparation

[0037] The ingredients are calculated by mole percentage as:

[0038]

[0039] Put the synthesized EDDHA in a reaction kettle, heat to 65-75°C, and stir. under stirring

[0040] Slowly add ZnSO 4 , MnSO 4 , FeSO 4 Solution, keep stirring for 1h to obtain iron, manganese...

example 2

[0041] Example 2: EDDHA chelated binary compound micro-fertilizer of iron and zinc

[0042] 1. Synthesis of EDDHA

[0043]

[0044] Put the above chemical reagents in a reaction kettle, heat to 65-75°C, and stir. Add ethylenediamine dropwise under stirring, then slowly add 50% glyoxylic acid dropwise, and keep it for 1~2h.

[0045] 2. Preparation of trace element ion solution

[0046] The molar ratio of ingredients is

[0047] Zinc sulfate 0.5

[0048] Ferrous sulfate 0.5

[0049] At room temperature, the above solid powders were respectively dissolved in 150ml of water, and stirred until completely dissolved.

[0050] 3. Chelate preparation

[0051] The ingredients are calculated by mole percentage as:

[0052] EDDHA60

[0053] ZnSO 4 20

[0054] FeSO 4 20

[0055] Put the synthesized EDDHA in a reaction kettle, heat to 65-75°C, and stir. Slowly add ZnSO separately under stirring 4 , FeSO 4 solution, keep stirring for 1h to obtain iron and zinc EDDHA chelate...

example 3

[0056] Example 3: EDDHA chelated binary compound micro-fertilizer of iron and manganese

[0057] 1. Synthesis of EDDHA

[0058]

[0059]

[0060]Put the above chemical reagents in a reaction kettle, heat to 65-75°C, and stir. Ethylenediamine was added dropwise with stirring, and then 50% glyoxylic acid was slowly added dropwise for ~2h.

[0061] 2. Preparation of trace element ion solution

[0062] The molar ratio of ingredients is

[0063] Manganese sulfate 0.5

[0064] Ferrous sulfate 0.5

[0065] At room temperature, the above solid powders were respectively dissolved in 150ml of water, and stirred until completely dissolved.

[0066] 3. Chelate preparation

[0067] The ingredients are calculated by mole percentage as:

[0068] EDDHA60

[0069] MnSO 4 20

[0070] FeSO 4 20

[0071] Put the synthesized EDDHA in a reaction kettle, heat to 65-75°C, and stir. Slowly add MnSO separately under stirring 4 , FeSO 4 solution, kept stirring for 1h. A chelate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com