Method for producing high-activity nano magnesia by utilizing low-grade magnesite

A nano-magnesium oxide and magnesite technology, applied in magnesium oxide, magnesium hydroxide and other directions, can solve the problems of mine vegetation restoration and low comprehensive utilization of resources, and achieve the effect of high added value and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

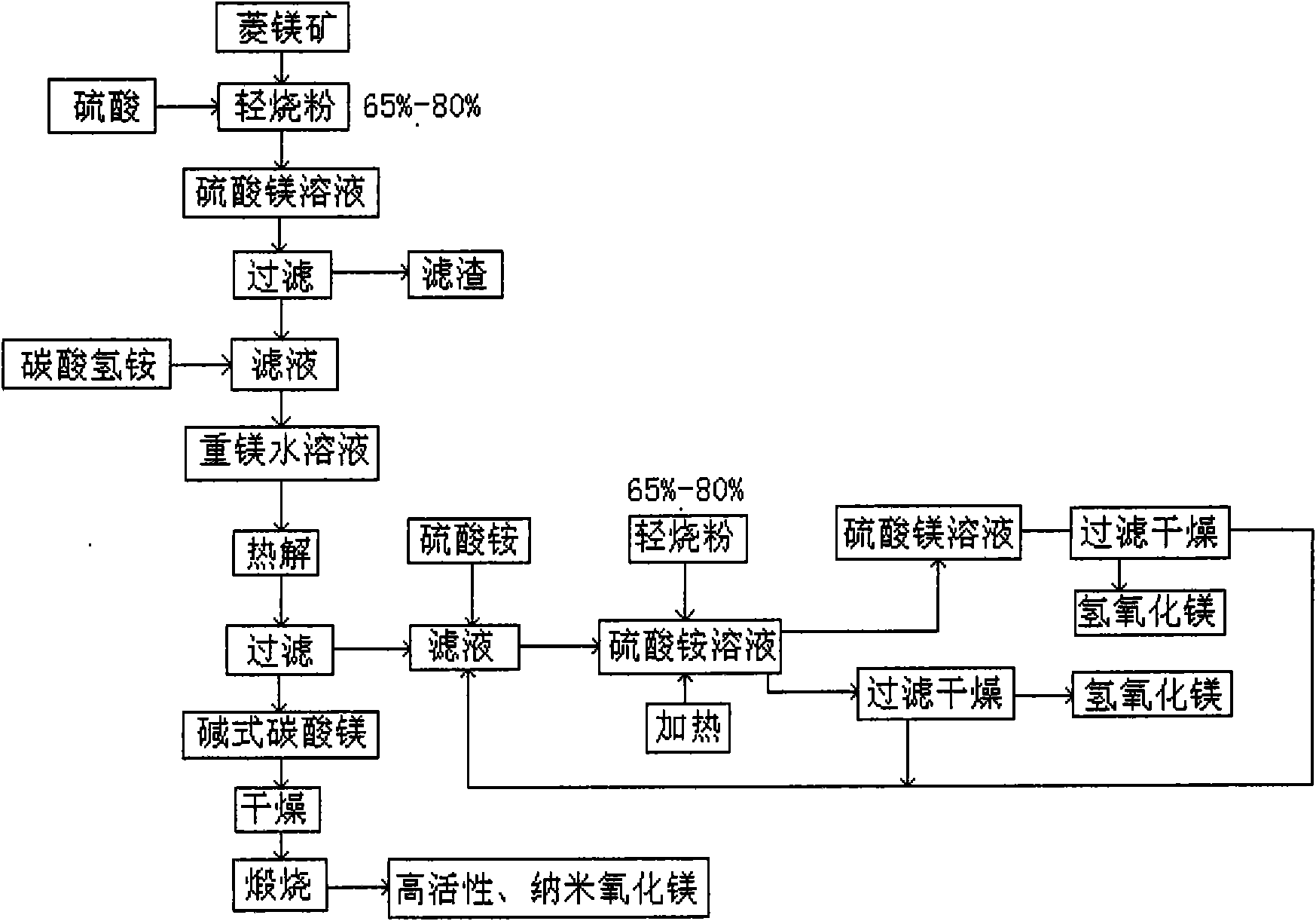

[0051] Take 100g of lightly burned powder (magnesia content between 65%-80%), add dilute sulfuric acid made of 120ml of water and 60-120ml of concentrated sulfuric acid, heat to 75°C, react for 2h, filter while hot to remove insoluble matter, A crude magnesium sulfate solution 1 was obtained.

[0052]Measure 200ml of crude magnesium sulfate solution, heat it up to 45°C-50°C, add 3-5g of MgO to the solution in several times for reaction, stir for 5 minutes, add 4ml of hydrogen peroxide dropwise, a reddish-brown precipitate is produced, filter to obtain Contains MgSO 4 The filtrate contains substantially no other impurities.

[0053] According to mass ratio 3 / 1(NH 4 HCO 3 / MgSO 4 ), adding NH to the purified magnesium sulfate filtrate 4 HCO 3 (Temperature 40°C) to generate heavy magnesium aqueous solution, add 3% (mass ratio of OP emulsifier to magnesium bicarbonate) OP emulsifier. When the temperature is 70°C to 105°C, the pyrolysis reaction of magnesium carbonate occurs,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com