Method for refining magnesium and reducing silicon from magnesite ores

A magnesite and ore technology, which is applied in the fields of reverse flotation extraction from magnesite ore to extract magnesium and reduce silicon, and magnesite ore to extract magnesium and reduce silicon, which can solve the complex composition of gangue minerals and increase the difficulty of sorting, etc. problem, to achieve the effect of low foam viscosity, strong practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

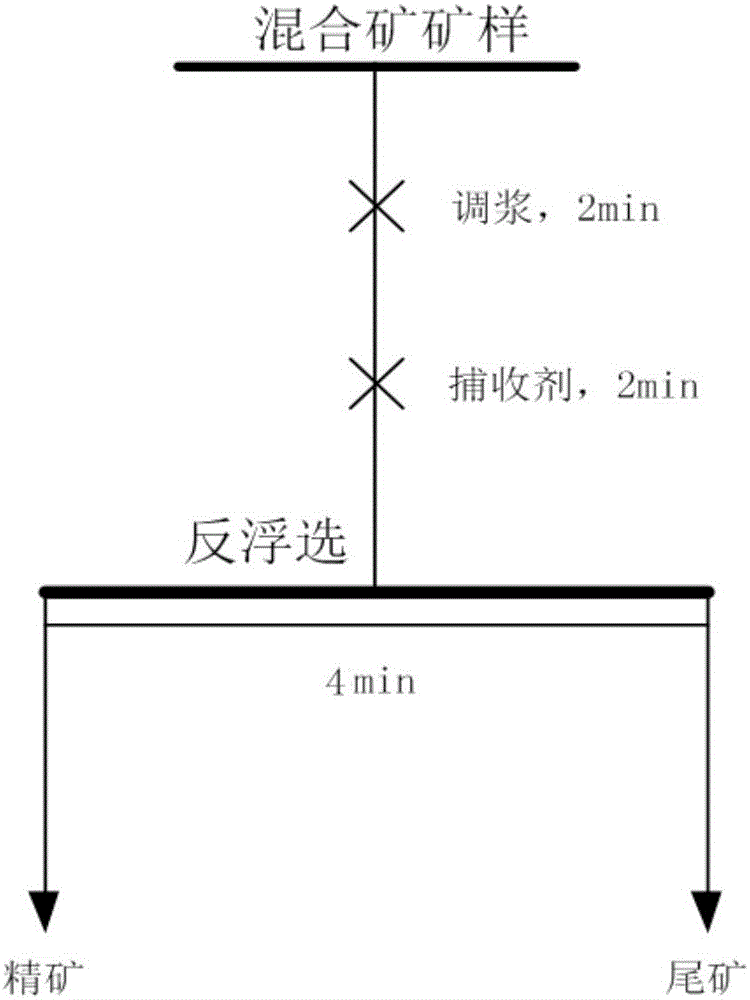

[0028] (1) Quartz and magnesite are configured into a mixed ore sample according to a mass ratio of 3:97, the ore sample is weighed and put into a flotation cell, and deionized water is added to achieve a pulp concentration of 30%; Select the machine, under the condition of 1620r / min, stir and mix for 2min;

[0029] (2) After pulping, under normal temperature and under the natural pH condition of the pulp, add collector N,N-bis(hydroxyethyl)dodecylamine 50g / t, stir for 2min and then carry out flotation, the flotation time is 4min . After flotation, dry and weigh the foam product and the product in the tank respectively, take samples to test the grade, and calculate the recovery rate, wherein the product in the tank is concentrate, and the MgCO in the reverse flotation concentrate 3 Grade 98.94%, MgCO 3 The recovery rate can reach 86.51%, SiO 2 The removal rate can reach 93.69%, SiO in the concentrate 2 The grade is only 0.17%.

[0030] Or, after pulping, add 50 g / t of col...

Embodiment 2

[0032] (1) Quartz and magnesite are configured into a mixed ore sample according to a mass ratio of 1:9, and the ore sample is weighed and put into a flotation cell, and deionized water is added to achieve a pulp concentration of 30%; Select the machine, under the condition of 1620r / min, stir and mix for 2min;

[0033] (2) After pulping, under normal temperature and under the natural pH condition of the pulp, add collector N,N-bis(hydroxyethyl)dodecylamine 50g / t, stir for 2min and then carry out flotation, the flotation time is 4min . After flotation, dry and weigh the foam product and the product in the tank respectively, take samples to test the grade, and calculate the recovery rate, wherein the product in the tank is concentrate, and the MgCO in the reverse flotation concentrate 3 Grade 98.73%, MgCO 3 The recovery rate can reach 86.35%, SiO 2 The removal rate can reach 95.67%, SiO in the concentrate 2 The grade is 0.38%.

[0034] Or, after pulping, add 50 g / t of colle...

Embodiment 3

[0036](1) Quartz and magnesite are configured into a mixed ore sample according to a mass ratio of 1:9, and the ore sample is weighed and put into a flotation cell, and deionized water is added to achieve a pulp concentration of 30%; Select the machine, under the condition of 1620r / min, stir and mix for 2min;

[0037] (2) After pulping, add collector N,N-bis(hydroxyethyl)dodecylamine 60g / t under normal temperature and natural pH condition of pulp, stir for 2min and carry out flotation, the flotation time is 4min . After flotation, dry and weigh the foam product and the product in the tank respectively, take samples to test the grade, and calculate the recovery rate, wherein the product in the tank is concentrate, and the MgCO in the reverse flotation concentrate 3 Grade 98.72%, MgCO 3 The recovery rate can reach 83.46%, SiO 2 The removal rate can reach 96.26%, SiO in the concentrate 2 The grade is 0.36%.

[0038] Or, after slurry mixing, add collector N,N-di(hydroxypropyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com