Method for preparing magnesium with silica-alumina alloy as electronating agent

A silicon-aluminum alloy and reducing agent technology, applied in the metallurgical field, can solve the problems of poor economic benefits, high pressure of agglomeration, and low recovery rate of metal magnesium, and achieve the effects of reducing equipment investment, increasing profits and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

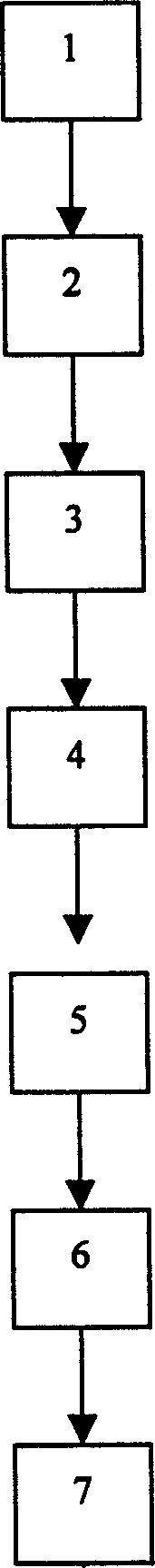

Method used

Image

Examples

Embodiment 1

[0028] Ratio of charge: calcined dolomite 2100 kg, caustic magnesite 500 kg,

[0029] Silicon aluminum alloy (60% Al+40% Si) 600 kg;

[0030] Conditions for implementation: the dough is in the dough making machine, the pressure is 300-500Kg / cm 2 ;

[0031] Grinding by ball mill, 100% passing through 100# sieve;

[0032] The temperature of the vacuum reduction furnace is 1000-1150°C, and the reduction time is 6-8 hours;

[0033] Implementation results: the output of magnesium is 667 kg, and the recovery rate of metal magnesium is 84%.

Embodiment 2

[0035] Ratio of charge: calcined dolomite 2100 kg, caustic magnesite 500 kg,

[0036] Silicon aluminum alloy (70% Al+30% Si) 600 kg;

[0037] Implementation conditions: same as above;

[0038] Implementation results: the output of magnesium is 674 kg, and the recovery rate of metal magnesium is 84%.

Embodiment 3

[0040] Ratio of charge: calcined dolomite 2100 kg, caustic magnesite 500 kg,

[0041] Silicon aluminum alloy (85.263% Al+14.737% Si) 600 kg;

[0042] Implementation conditions: same as above;

[0043] Implementation results: the output of magnesium is 710.6 kg, and the recovery rate of metal magnesium is 88.36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com