Magnesium-calcium-iron sand synthesized by taking dolomite and magnesite as raw materials and sintering and preparation method

A magnesia-calcium-iron sand and magnesite technology, applied in the field of refractory materials, can solve the problems of polluting environment products, complex production process and high production cost, and achieve the effects of reducing production cost, simple production process and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

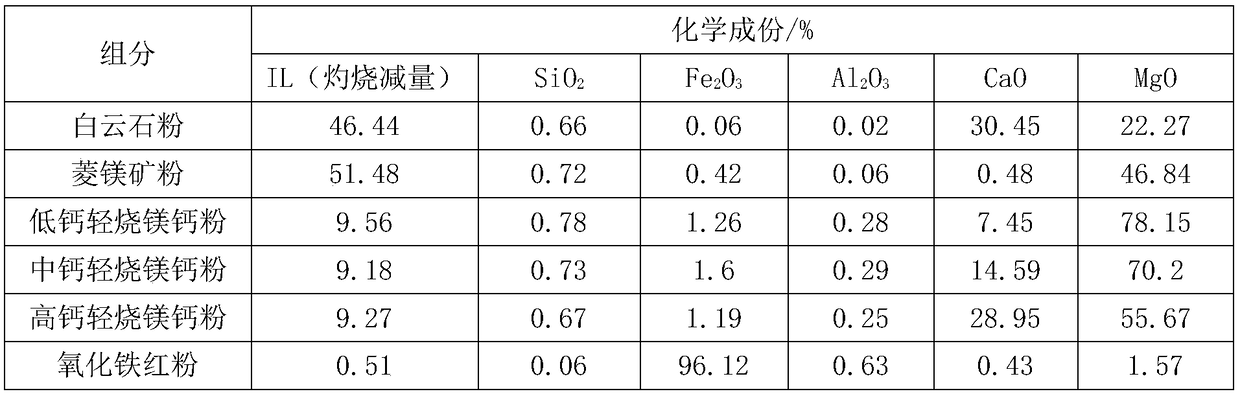

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of described magnesium calcium iron sand, comprises the steps:

[0032] 1) According to the proportion, put dolomite powder, magnesite powder, calcined magnesite powder and iron oxide red powder into the wet mill for kneading, add water with 25% to 35% of the total weight of raw materials, and stir for 30 to 40 minutes. It is in a state of holding hands into a ball and then loosening hands;

[0033] 2) Use a briquetting machine to press into magnesia-calcium-iron balls, or use a brick press to make magnesia-calcium-iron adobes, and the bulk density of the balls or adobes is > 2.3g / cm 3 ;

[0034] 3) The formed magnesium-calcium-iron balls or magnesium-calcium-iron bricks are sent to a drying kiln at a drying temperature of 50-80°C for more than 24 hours, and then sent to a high-temperature sintering device for sintering;

[0035] 4) Crushing the sintered magnesia-calcium-iron balls or magnesia-calcium-iron bricks to produce magnesia-calcium-iron s...

Embodiment 1-3

[0045] In embodiment 1-3, the preparation method of magnesium calcium iron sand is as follows:

[0046] 1) Batching: carry out the batching of each component according to Table 2.

[0047] 2) Mixing: put dolomite powder, magnesite powder, calcined magnesite powder and iron oxide red powder into the wet mill and knead, add water and stir for 30-40 minutes, (wherein Example 1 stirs for 32 minutes, Example 2 Stir for 35 minutes, Example 3 stirred for 38 minutes), ensure that the mixing is even, the water content of the mud after mixing is 25%~35% (wherein Example 1 is 28%, Example 2 is 30%, Example 3 33%), make the mud material reach the state of loosening after letting go of the hand into a ball, and then discharge.

[0048] 3) Molding: Send the mixed mud to the molding workshop, use a ball press to press into balls, or use a friction brick press to press into bricks, and the volume density of the formed magnesia-calcium-iron balls or magnesia-calcium-iron bricks is required G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com