Process for producing high purity magnesium oxide monocrystal using waste magnesite ore

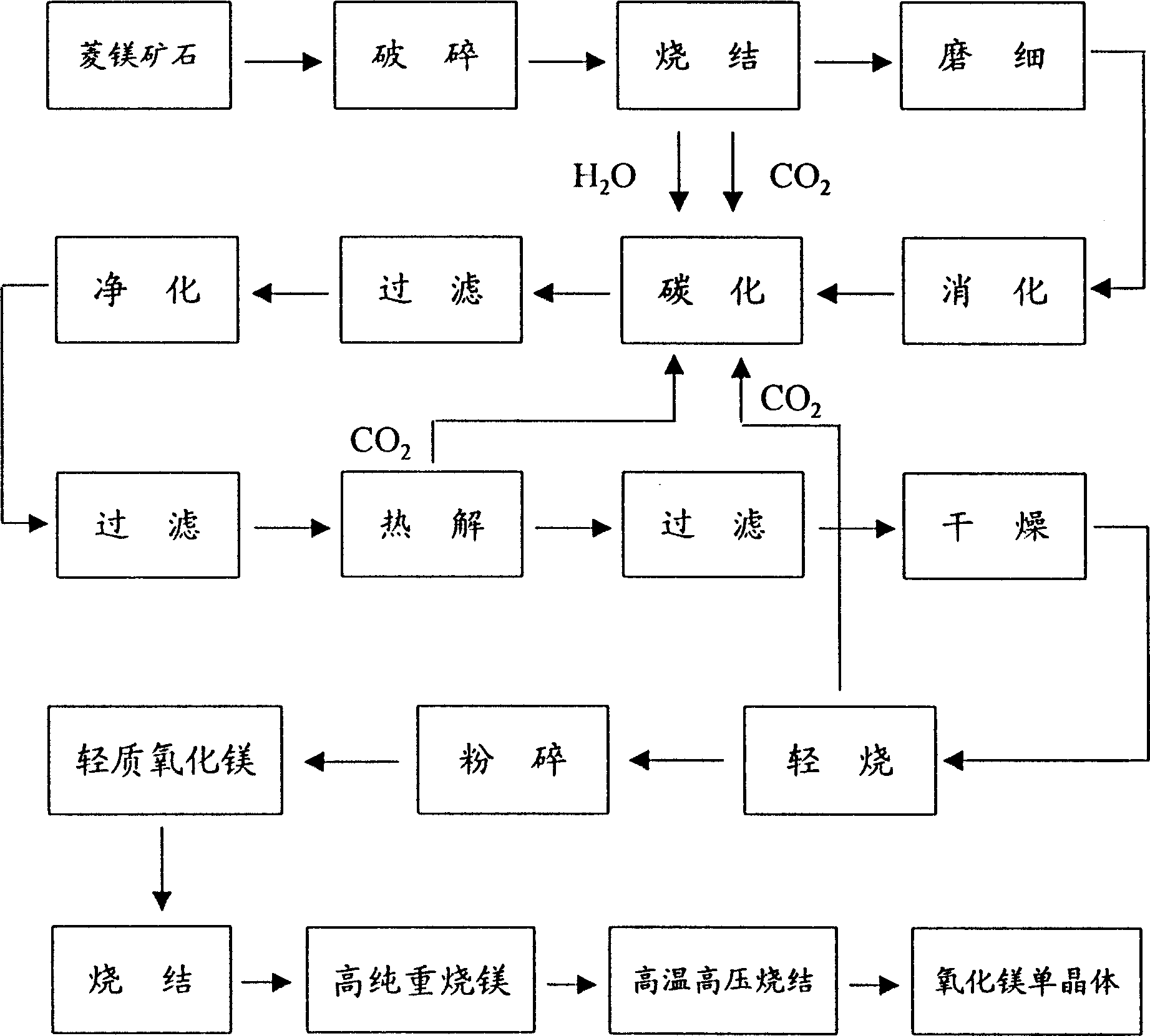

A magnesite ore and production method technology, which is applied in the field of producing high-purity magnesium oxide single crystal from waste sub-magnesite ore, can solve the problems of polluting the environment, not meeting the sustainable development strategy, not meeting the clean production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Crush the magnesite ore to a particle size of about 200 mm, put it into a reverberatory furnace (lime kiln) and burn it at 800°C for 2 hours to obtain lightly burned magnesium. After cooling, take it out of the furnace, add water to the melting pool, stir it and pass it through ball milling. 120-mesh sieve, add water and digest for 3 hours, then pump into the carbonization pressure tank according to the solid-liquid ratio of 1:25, add water, keep the temperature of the reaction tank at 20°C, and feed CO with a concentration of 30-40% into the tank. 2 Gas, while constantly stirring, check the pH of the reaction tank after 40 minutes, and stop ventilation and stirring when it is slightly acidic. After the slurry in the tank is filtered by a scraper filter, it is poured into the storage tank and purified with a purifying agent, and then finely filtered, the aqueous solution flows into the pyrolysis tank, and is heated to 80-100°C by passing in superheated steam. At this tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com