Light burning system and method of magnesite

A magnesite and light burning technology, applied in lime production and other directions, can solve the problems of unstable quality, low automation and high heat consumption of light burning MgO powder, and achieve easy control and adjustment, high automation and low heat consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

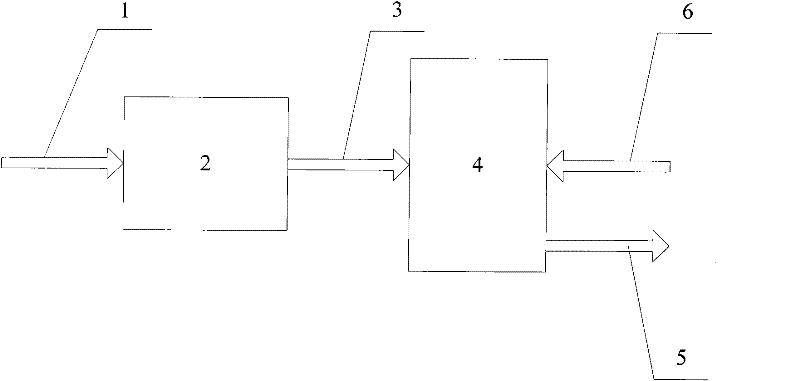

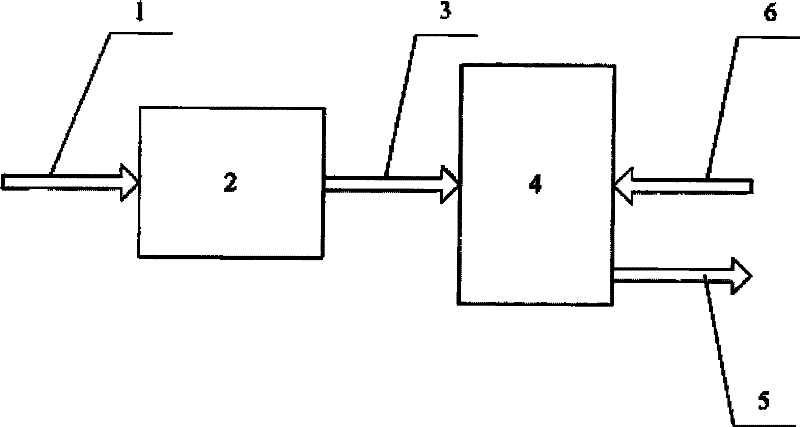

[0019] Such as figure 1 As shown, the magnesite light burning system of the present invention is composed of the following structures: ore crushing and grinding system 2, ore crushing and grinding system 2 sends ore to roasting furnace system 4 through feeding and conveying equipment 3, and roasting furnace system 4 Output the lightly burned magnesium oxide powder through the discharge conveying equipment 5, and the roaster system 4 is connected to the fuel supply system 6; the roaster in the roaster system is a gaseous suspension roaster, a fluidized flash roaster or a circulation Roasting furnace; the fuel in the fuel supply system 6 is natural gas, producer gas or coke oven gas; heavy oil or light oil; coal or petroleum coke.

[0020] The gaseous suspension roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com