Method for producing magnesium ammonium phosphate fertilizer by using light roasting powder to process phosphorus-containing and nitrogen-containing waste water

A technology of ammonium magnesium phosphate and light burning powder, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of natural ecological environment hazards, mining cost waste, etc., and achieve good economic benefits and environmental protection Benefits, reduced production costs, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

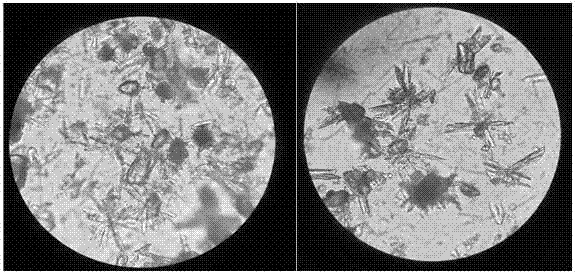

[0032] Take 100mL nitrogen-phosphorus ratio m(N):m(P)=0.4 (N concentration is 120mg / L, P concentration is 300mg / L) phosphorus-containing and nitrogen-containing simulated wastewater 6 parts respectively in 6 large beakers, of which Add 0.7g of 65% lightly burned powder to each of 3 parts, add 0.7g of 89% lightly burned powder to each of the other 3 parts, stir at a stirring speed of 150r / min for 25min, settle for 30min; take the supernatant to measure nitrogen and phosphorus content, calculate the removal rate of nitrogen and phosphorus, and at the same time take the precipitate and observe the shape of the precipitate under a microscope. The results are shown in the table below and attached figure 1 .

[0033] 65% lightly burned powder denitrification and phosphorus removal results

[0034]

[0035] 89% denitrification and dephosphorization results of lightly burned powder

[0036]

Embodiment 2

[0038] Take 100mL nitrogen-phosphorus ratio as n(N):n(P)=1.0:1.0, substance concentration is 0.1mol / L, (N concentration is 1400mg / L, P concentration is 3100mg / L) phosphorous and nitrogenous simulated wastewater Put 6 parts into 6 large beakers respectively, change the dosage of 65% lightly burned powder, stir at a stirring speed of 150r / min for 25min, and settle for 60min; take the supernatant to measure the content of nitrogen and phosphorus, and calculate the removal of nitrogen and phosphorus At the same time, the precipitate was taken to observe the shape of the precipitate under a microscope, and the results are shown in the table below.

[0039] Nitrogen and phosphorus removal results of high concentration nitrogen and phosphorus wastewater by 65% lightly burned powder

[0040]

Embodiment 3

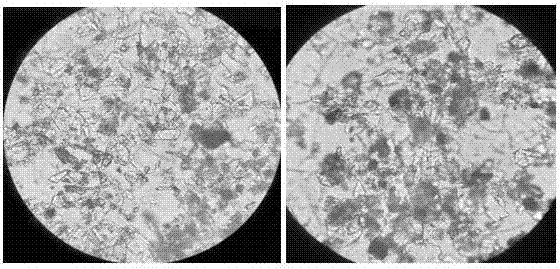

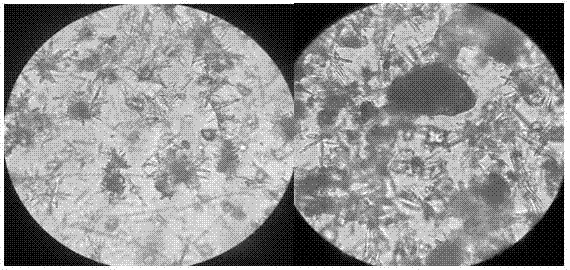

[0042] Take 10 parts of 800mL phosphorus-containing simulated wastewater with a phosphorus concentration of 300mg / L and place them in 10 large beakers respectively, 5 parts of which are added with 8g of 65% lightly burned powder, and the other 5 parts are added with 89% lightly burned powder 6.4 g, stir at a stirring speed of 150r / min for 25min, settle for 3h; take the supernatant to measure the phosphorus content, calculate the phosphorus removal rate, and take the precipitate to observe the shape of the precipitate under a microscope, and dry the precipitate for later use. The results are shown in the table below and attached drawings.

[0043]Take 8 parts of 100mL nitrogen-containing simulated wastewater with a nitrogen concentration of 150mg / L and place them in 8 large beakers respectively, of which 4 parts are added with 65% lightly burned powder to treat 0.9g of phosphorus-containing wastewater sediment, and the other 4 parts are each Add 89% lightly burned powder to tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com