Manganese-doped maghemite catalyst used for thermal catalytic oxidation of formaldehyde, and preparation method thereof

A technology of maghemite and manganese doping, which is applied in the field of manganese-doped maghemite catalyst and its preparation, can solve the problems of low catalytic activity, high price, easy loss, etc., and achieve high catalytic activity and thermal stability Good, low ignition temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh 27.8g FeSO 4 ·7H 2 O (0.1mol), 54.1g FeCl 3 ·6H 2 O (0.2mol) was added into 400mL ultrapure water (x=0), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3+ solution of metal ions.

[0019] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete; then crystallize the black precipitate at a constant temperature of 90°C for 24 hours .

[0020] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, freeze-dry in vacuum at a temperature of -40~-50°C for 24 hours, and obtain granular manganese-doped Magnetite precursor.

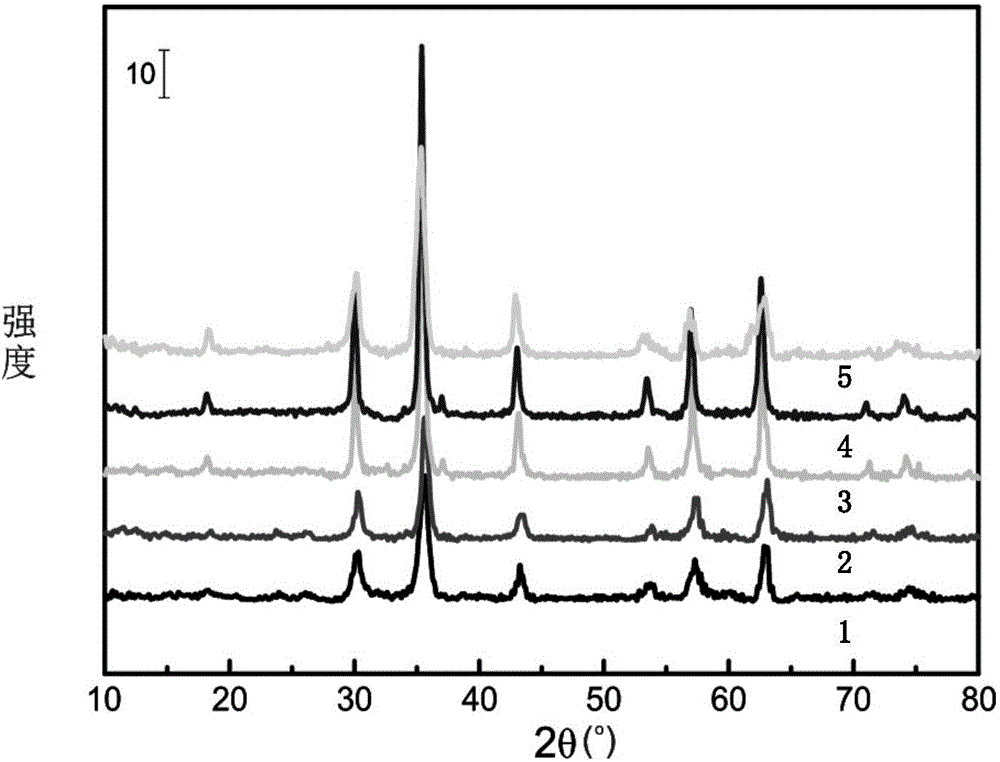

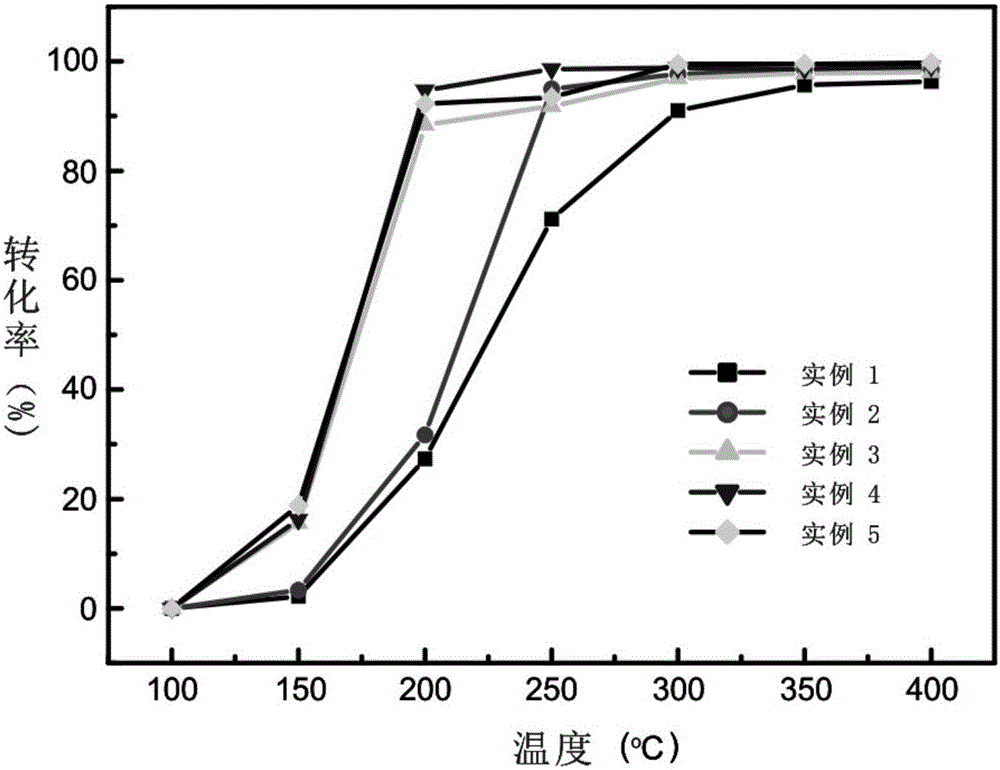

[0021] 4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it at 450° C. for 4 hours to obtain a composite sample 1 .

[0022] 5. Id...

Embodiment 2

[0024] 1. Weigh 22.2g FeSO 4 ·7H 2 O (0.08mol), 54.1g FeCl 3 ·6H 2 O (0.2mol), 3.4g MnSO 4 ·H 2 O (0.02mol) was added into 400mL ultrapure water (x=0.2), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3+ , Mn 2+ solution of metal ions.

[0025] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete; then crystallize the black precipitate at a constant temperature of 90°C for 24 hours .

[0026] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, and freeze-dry at a temperature of -40 to -50°C for 24 hours in a vacuum. After drying, granular manganese-doped magnetic Iron ore precursors.

[0027] 4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it at 450...

Embodiment 3

[0030] 1. Weigh 13.9g FeSO 4 ·7H 2 O (0.05mol), 54.1g FeCl 3 ·6H 2 O (0.2mol), 8.5g MnSO 4 ·H 2 O (0.05mol) was added into 400mL ultrapure water (x=0.5), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3+ , Mn 2+ solution of metal ions.

[0031] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete, and then crystallize the black precipitate at a constant temperature of 100°C for 24 hours .

[0032] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, and freeze-dry at a temperature of -40 to -50°C for 24 hours in a vacuum. After drying, granular manganese-doped magnetic Iron ore precursors.

[0033]4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com