Animal magnetic ferritin material and its preparation method

An animal ferritin and animal magnetism technology, which is applied in the field of biomimetic synthesis of magnetic nanomaterials, can solve the problem that the product has a single composition, cannot remove in vitro mineralization by-products and ferritin aggregates, and is difficult to control dissolved oxygen and ferrous ions. Proportion and other issues, to achieve the effect of simple and feasible purification method, avoiding immunogenicity and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

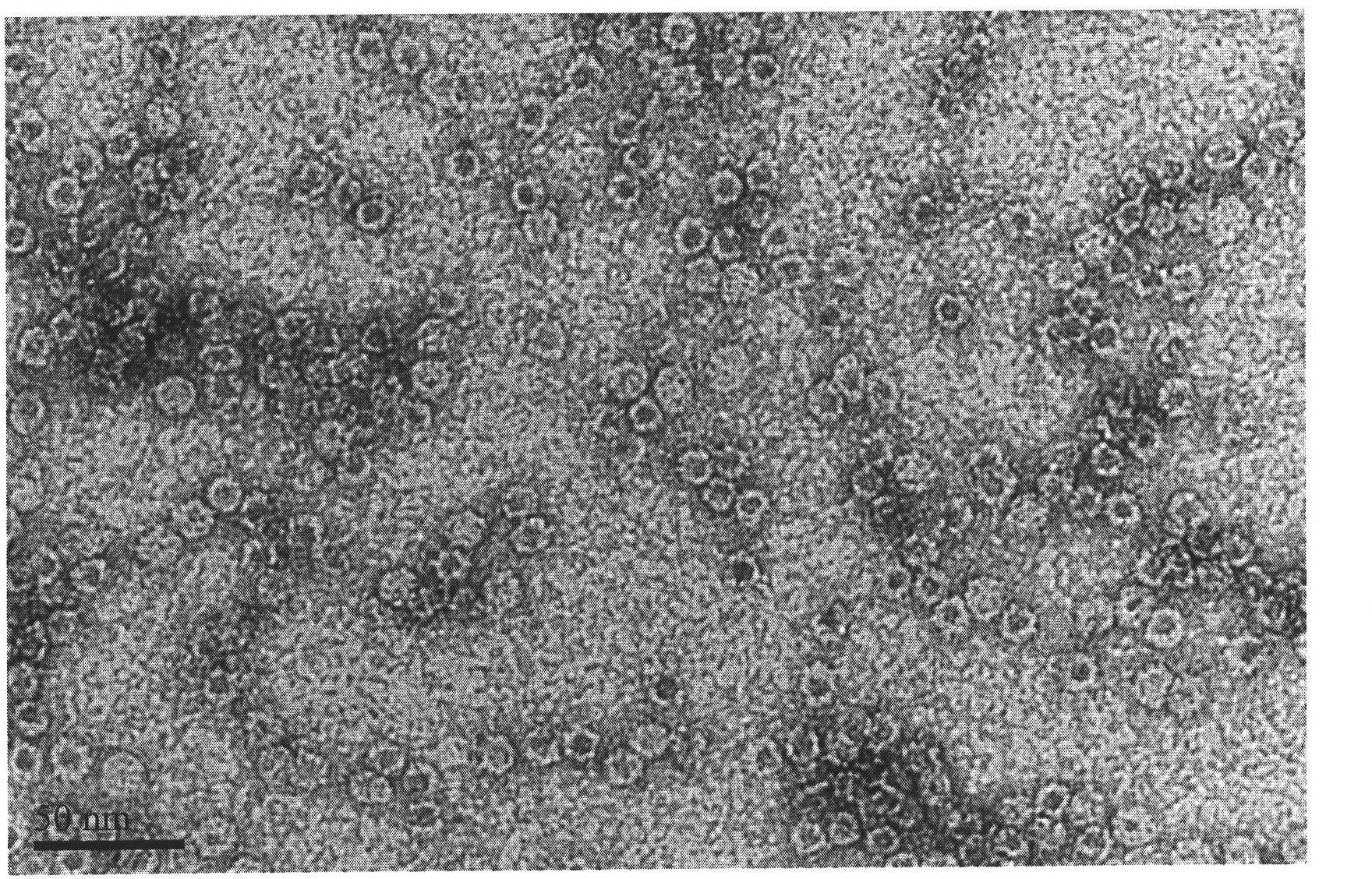

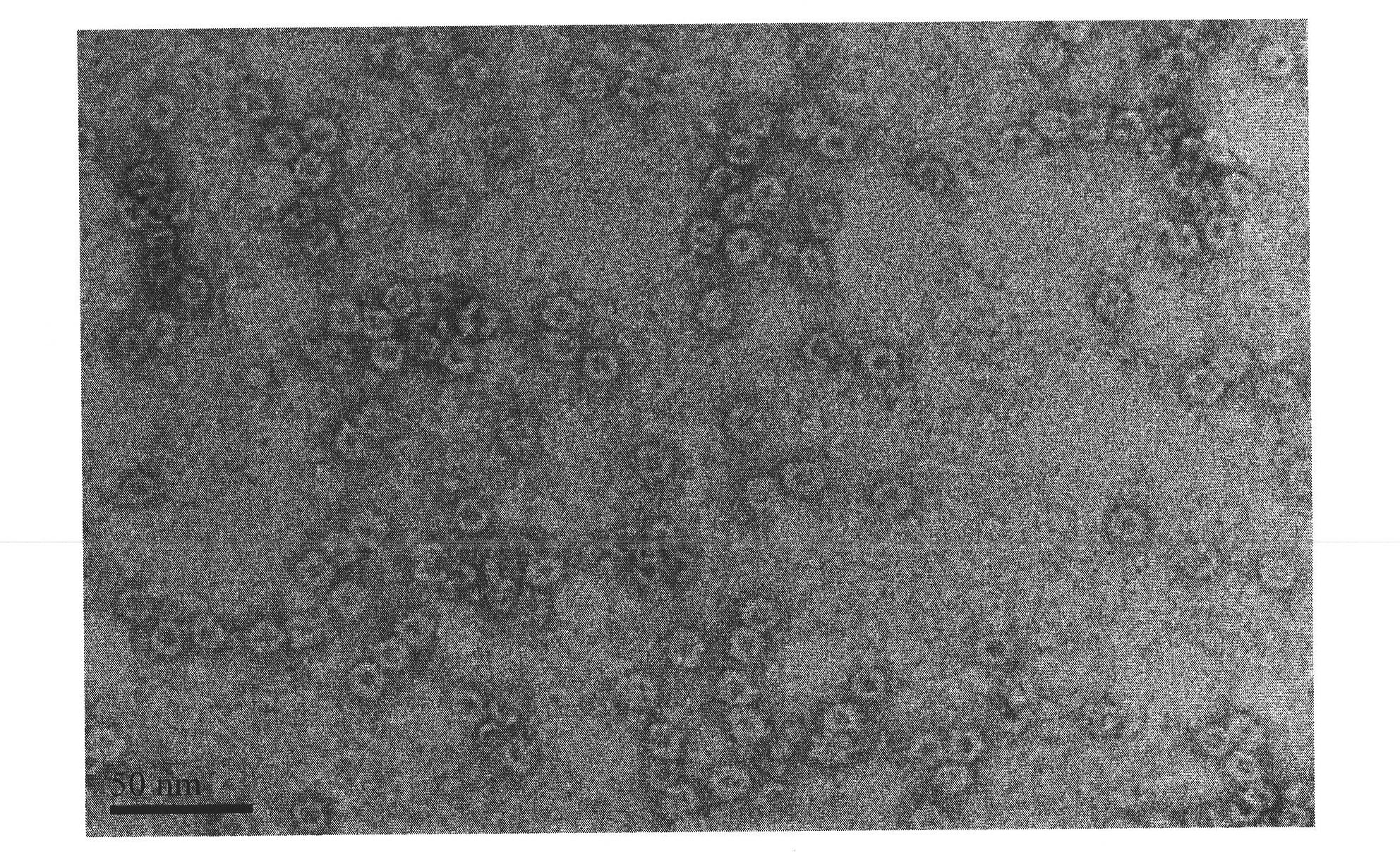

[0045] In an anaerobic glove box, 50ml of 25mM ammonium ferrous sulfate and 8.34mM of H 2 o 2 50ml, the NaOH 100ml of 100mM NaCl solution and 50mM, the empty shell porcine spleen ferritin solution ( figure 2 ) was diluted with 100mM NaCl solution to a volume of 50ml, the final protein concentration was 0.25mg / ml, and put into the cuvette. First, use a heating mantle to heat the protein solution in the reaction cup to 65°C. During heating, add a stir bar and stir quickly with magnetic force to ensure that the temperature of the solution is uniform. After the temperature is constant for 15 minutes, use 50mM NaOH to adjust the pH value of the protein solution through a constant pH titrator. to 8.5, then add ferrous ammonium sulfate and H 2 o 2 Each 2.245ml, the iron content of final ferritin is 2300 iron atoms. Then, the synthesized magnetic porcine spleen ferritin is subjected to molecular sieve chromatography and electrophoresis to check the protein types corresponding to...

Embodiment 2

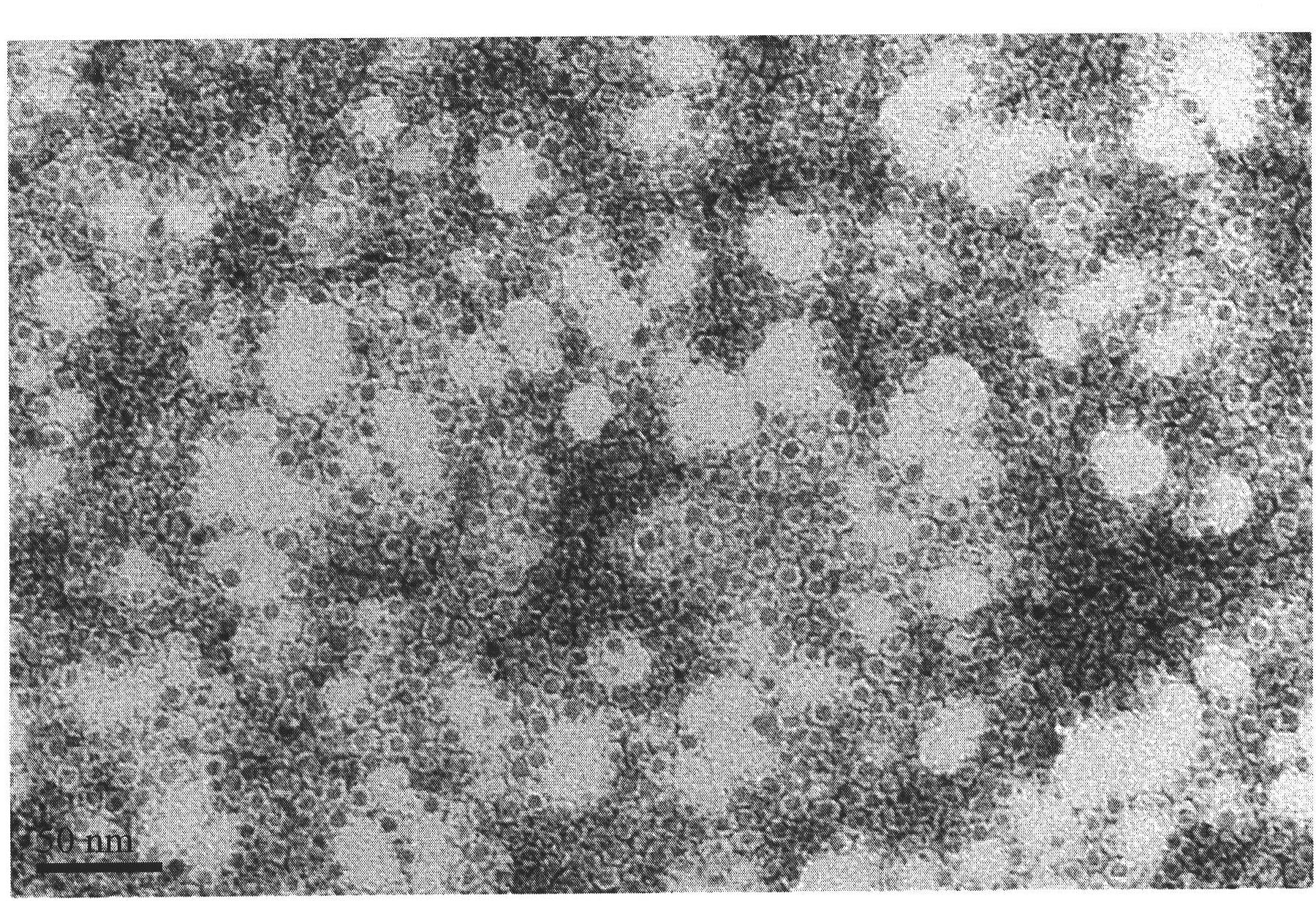

[0047] Dilute the purified empty-shell porcine spleen ferritin solution to 50 ml with deoxygenated 100 mM NaCl solution, and put it into a reaction cup. The final protein concentration is 1mg / ml. First, heat the protein solution in the reaction cup to 37°C with an electric heating mantle. During heating, add a stirrer and stir quickly with magnetic force to ensure that the solution temperature is uniform. After the temperature is constant for 15 minutes, use 50mM NaOH to titrate with constant pH The instrument adjusts the pH value of the protein solution to 8.5, and then adds ferrous ammonium sulfate and H 2 o 2 Each 2.245ml, the iron content of final ferritin is 2300 iron atoms. All the other operations are the same as in Example 1. Figure 4 It is a transmission electron microscope (TEM) negative staining photo of magnetic porcine spleen ferritin in an aggregated state before molecular sieve separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com