Purification and separation method of sucrose fatty acid ester

A technology of sucrose fatty acid ester and separation method, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of difficult organic wastewater treatment, complex process, large amount of organic solvent, etc., and achieve simple It is conducive to industrial production, broad market prospects, and convenient environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

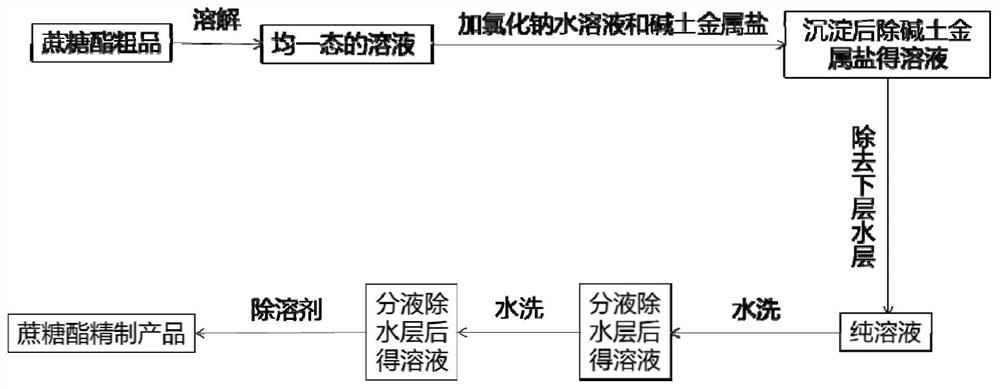

Image

Examples

Embodiment 1

[0023] (1) Dissolve and disperse 20.0 g of crude sucrose fatty acid ester in a mixed solution of 60.0 mL of ethyl acetate and 8.6 mL of water, stir and dissolve at 60°C for 30 min to obtain a crude sucrose fatty acid ester solution;

[0024] (2) Add 0.05 g / ml acetic acid solution to the crude sucrose fatty acid ester solution, adjust the pH to 7, stir for 10 min, and remove the insoluble matter by suction filtration;

[0025] (3) Transfer the sucrose fatty acid ester filtrate into a 250 mL beaker, slowly add 60 mL of sodium chloride aqueous solution with a mass fraction of 5%, stir for 15 min, add 1.2 g of barium chloride and let stand for 30 min after stirring, pump Barium salts were removed by filtration and the aqueous layer was drained;

[0026] (4) The filtrate was left to stand at 63°C for 30 min, the organic phase was washed twice with distilled water and then the water layer was discharged. The resulting solution was rotary evaporated to remove the organic solvent, the...

Embodiment 2

[0028] (1) Dissolve and disperse 20.0 g of crude sucrose fatty acid ester in a mixed solution of 100.0 mL of methyl ethyl ketone and 1.0 mL of water, stir and dissolve at 60°C for 30 min to obtain a crude sucrose fatty acid ester solution;

[0029] (2) Add 0.05 g / ml citric acid in one solution to the crude sucrose fatty acid ester solution, adjust the pH to 7, stir for 10 min, and remove the insoluble matter by suction filtration;

[0030] (3) Transfer the sucrose fatty acid ester filtrate into a 250 mL beaker, slowly add 60 mL of sodium chloride aqueous solution with a mass fraction of 5%, stir for 15 min, add 1.0 g of calcium chloride, stir and let stand for 30 min, pump Filter to remove calcium salts and drain the aqueous layer;

[0031] (4) The filtrate was left to stand at 63°C for 30 min, the organic phase was washed twice with distilled water, and then the water layer was discharged. The obtained solution was rotary evaporated to remove the organic solvent, then freeze-...

Embodiment 3

[0033] (1) Dissolve and disperse 20.0 g of crude sucrose fatty acid ester in a mixed solution of 40.0 mL of ethyl acetate and 40.0 mL of water, stir and dissolve at 60°C for 30 min to obtain a crude sucrose fatty acid ester solution;

[0034] (2) Add 0.05 g / mL hydrochloric acid solution to the crude sucrose fatty acid ester solution, adjust the pH to 7, stir for 10 min, and remove the insoluble matter by suction filtration;

[0035] (3) Transfer the sucrose fatty acid ester filtrate into a 250 mL beaker, slowly add 60 mL of sodium chloride aqueous solution with a mass fraction of 5%, stir for 15 min, add 1.5 g of calcium chloride, stir and let stand for 30 min, pump Filter to remove calcium salts and drain the aqueous layer;

[0036] (4) The filtrate was left to stand at 63°C for 30 minutes, the organic phase was washed twice with distilled water and then the water layer was discharged. The obtained solution was rotary evaporated to remove the organic solvent, then freeze-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com