Device for removing NOx (Nitrogen Oxide), SO2 (Sulfur Dioxide) and PM2.5 (Particulate Matter 2.5) simultaneously

A SO2 removal technology, applied in chemical instruments and methods, using liquid separating agents, dispersing particle separation, etc., can solve problems such as the predominance of target bacteria, overcome the inhibition problems of oxygen and temperature, and reduce secondary pollution. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

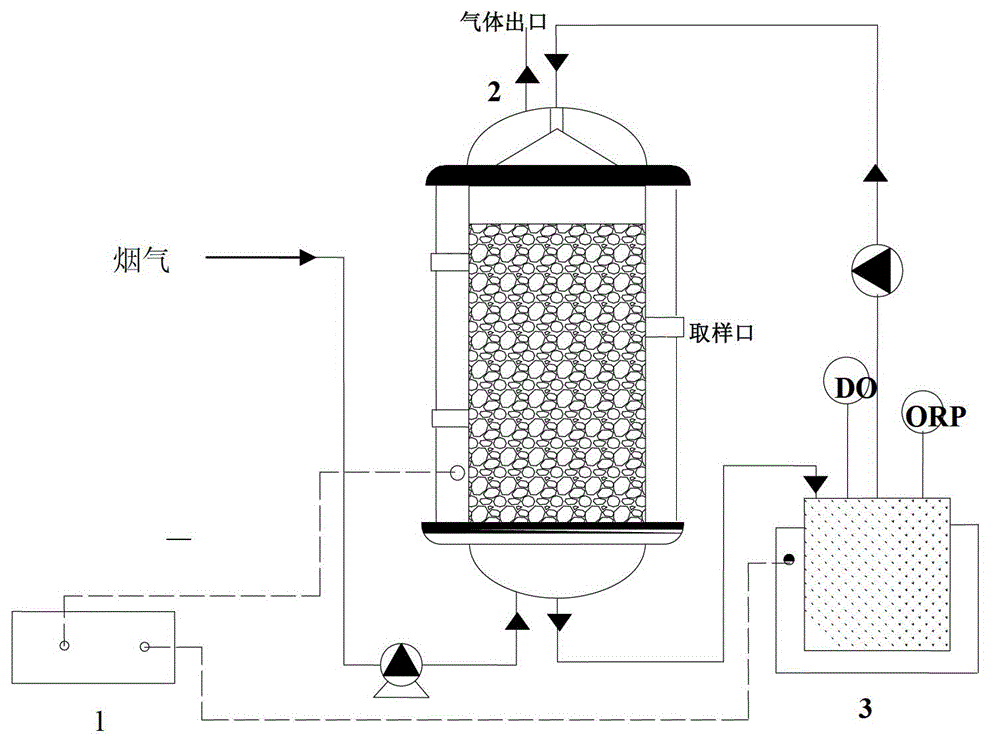

[0032] A simultaneous removal of NOx, SO 2 and PM 2.5 devices such as figure 1 As shown, it includes a control system 1, a biotrickling filter tower 2 and a microbial activity regenerator 3. The biotrickling filter tower 2 is provided with a packing layer loaded with biofilm, and the microbial activity regenerator 3 is equipped with microbial nutrient solution and newly cultivated targets. Bacteria liquid; the bottom of the biological trickling filter tower 2 communicates with the microbial activity regenerator 3, and the biological activity regenerator 3 communicates with the top of the biological trickling filter tower 2 through a pump, and the top of the biological trickling filter tower 2 is also provided with an exhaust port; controlled by the control system 1 controls the flue gas to be sent to the bottom of the biological trickling filter tower 2, and the control system 1 also controls the liquid in the microbial activity regenerator 3 to be pumped into the top of the ...

Embodiment 2

[0038] The main components and concentration of exhaust gas from a small boiler: NOx100mg / m 3 , SO 2 80mg / m 3 , O 2 8%, CO 2 11%, PM 2.5 The content is 420μg / m 3 , the inlet temperature is 40-50℃, and the average volume flow rate of exhaust gas is 1000m 3 / h.

[0039] (1) According to the amount of gas to be treated, the packing layer of the bio-trickling filter tower is determined to be two layers, and the flow rate of the circulating liquid is 250L / h. The cultured composite bacteria are inoculated on the packing, and the film is formed by mixing the packing and the culture solution. , so that the microorganisms are well loaded on the surface of the packing, and then loaded into the packing tower. Then continue to hang the film for a period of time, and a layer of biofilm grows on the filler, indicating that the film hanging is successful.

[0040] (2) Use a heating rod to keep the temperature at 45°C for the circulating fluid, and keep the dissolved oxygen at 7.6mg / ...

Embodiment 3

[0043] Main components and concentrations of flue gas from a coal-fired power plant: NO700mg / m 3 , SO 2 520mg / m 3 , O 2 8%, CO 2 10%, PM 2.5 The content is 530μg / m 3 . The inlet temperature is 40-50℃, and the exhaust gas volume flow rate is about 10000m 3 / h.

[0044] (1) According to the amount of gas to be treated and the concentration of nitrogen oxides in the exhaust gas, the packing layer of the biological trickling filter tower is determined to be three layers. The total flow rate of circulating liquid is 1000L / h.

[0045] (2) Inoculate the cultured composite bacteria on the filler, and adopt the method of mixed culture of the filler and the culture medium to hang the film, so that the microorganisms are well loaded on the surface of the filler, and then loaded into the packed tower. Then continue to hang the film in the tower for a period of time, and a layer of biofilm grows on the filler, indicating that the film is successful.

[0046] (3) The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com