A composite shallow superposition plant growth module and its application

A plant growth, shallow layer technology, applied in the direction of climate change adaptation, sustainable biological treatment, biological water/sewage treatment, etc. Simple, high-efficiency processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

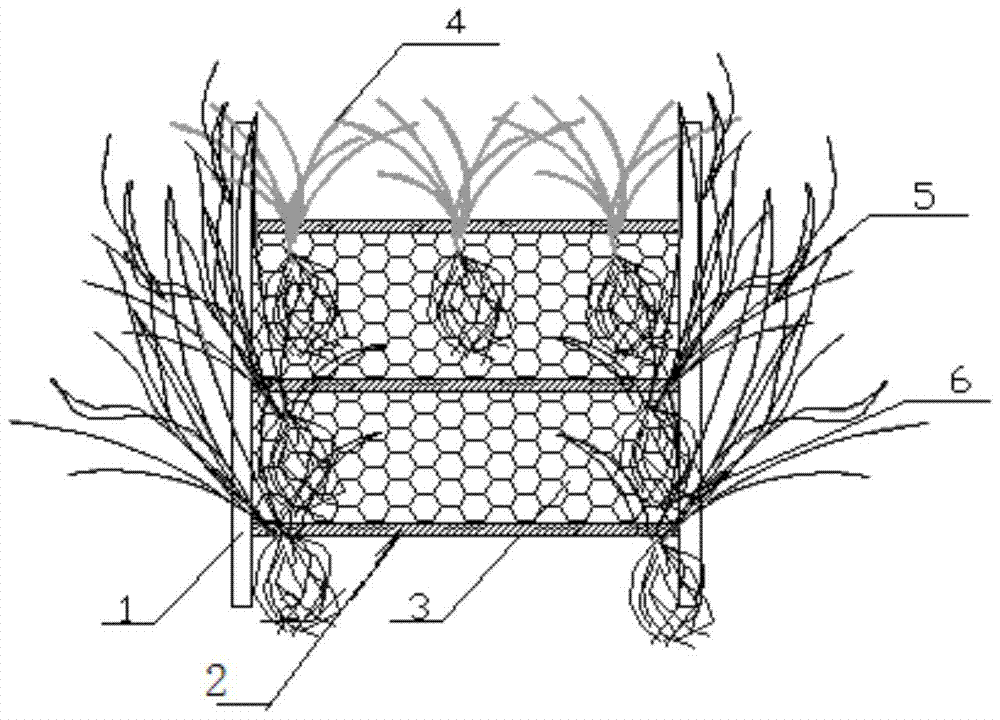

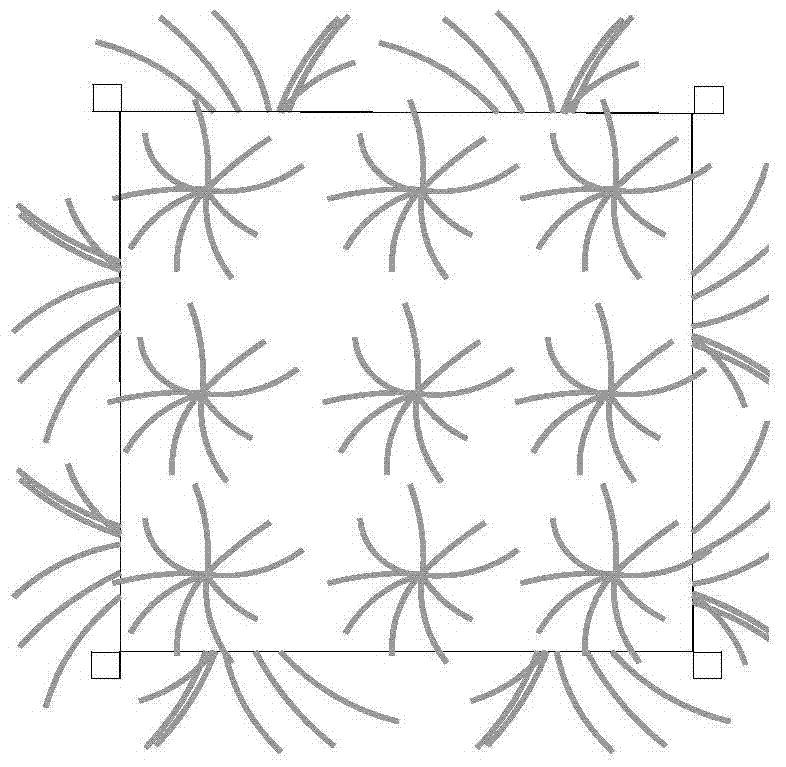

[0022] Such as figure 1 As shown, a composite shallow superimposed plant growth module for sewage treatment artificial wetlands is divided into three layers on the vertical direction of the module with partitions 2. The partitions 2 are PVC boards, which are the first layer and the second layer respectively. The four sides of the module are fixed by pillars 1, which are made of relatively hard UPVC pipes, and the pillars 1 are surrounded by nylon mesh 3 with low resistance. Wetland plants are planted on each layer of the module; planted on the first layer of the module Watercress, watercress, water spinach and other self-floating plants 4; the second layer is planted with rushes, calamus and other aquatic plants with stable roots and long rhizomes 5, the plants pass through the side nets, and the roots are fixed on the partitions of the second layer The third layer is planted with reeds and other aquatic plants with well-developed oxygen-secreting capacity 6, the plants pass t...

Embodiment 2

[0025] Basically consistent with embodiment 1, the difference is that watercress and other self-floating plants 4 are planted on the first layer of the module; aquatic plants 5 with long root systems such as calamus are planted on the second layer; clapboard 2 adopts glass fiber reinforced plastics; COD Mn The removal rate of 77%, TP removal rate of 72%, TN removal rate of 89%.

Embodiment 3

[0027] Basically consistent with embodiment 1, the difference is that self-floating plants 4 such as water spinach are planted on the first layer of the module; the second layer is planted with roots such as cattails and other aquatic plants with stable roots and longer rhizomes 5; COD Mn The removal rate of 79%, TP removal rate of 73%, TN removal rate of 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com