Beneficiation process of maghemite

An iron ore and process technology, which is applied in the field of hemagnetism mixed iron ore beneficiation process of high-grade iron ore concentrate, can solve the problems of difficulty in sales and difficulty in finding a market for concentrates, achieve a good separation effect and save equipment investment. and energy consumption, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

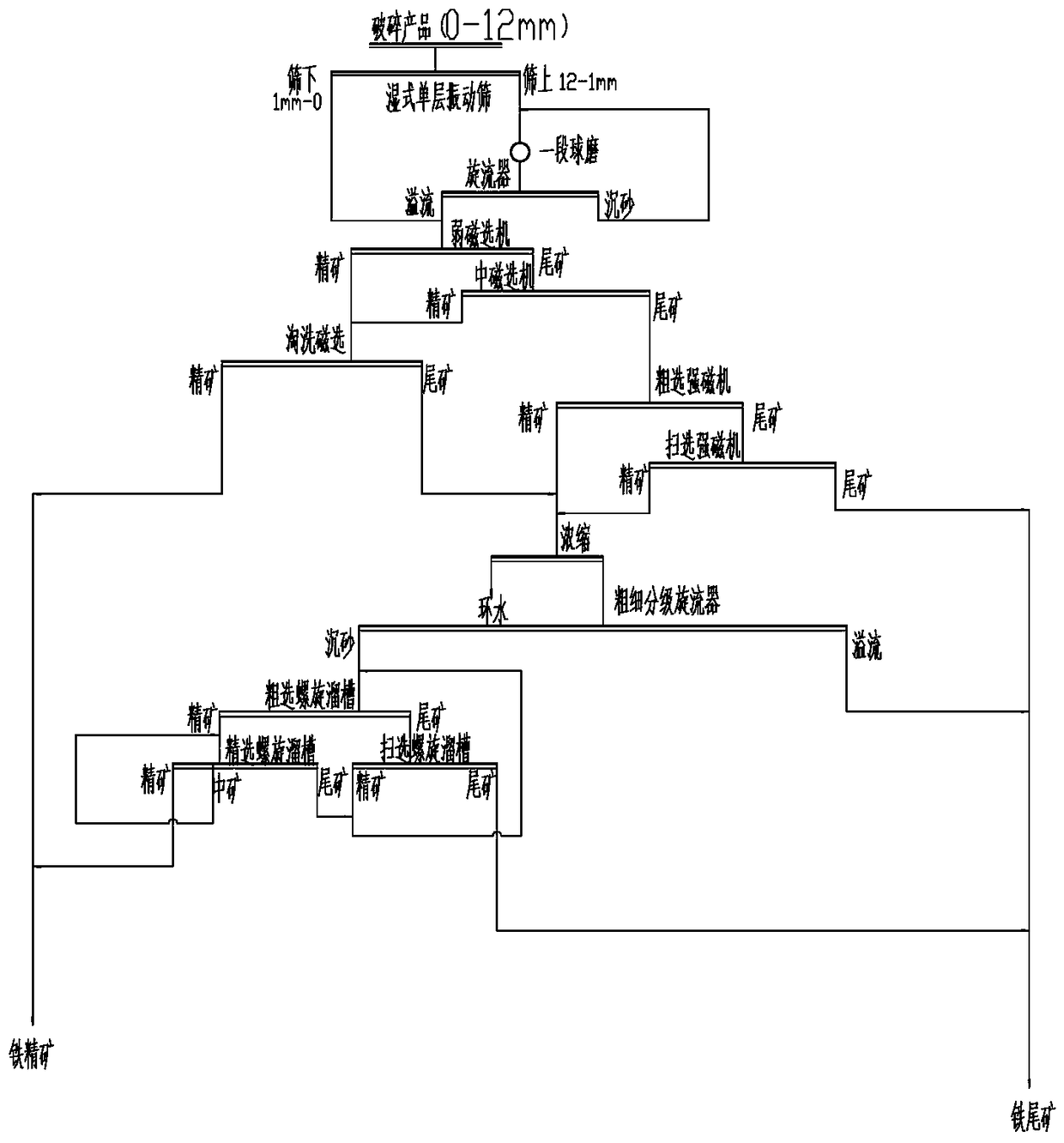

[0023] Such as figure 1 Shown: a kind of hematite mixed iron ore beneficiation process of the present invention, comprises that the iron grade is 42%, and the hematite mixed iron ore that iron-containing clay content is 30% in raw ore is fed into three section-closed-circuit crushing process, obtains particle size It is a crushed product of 12-0mm, which is characterized in that the processing of the crushed product adopts pre-grading + closed-circuit grinding process, magnetic separation process and gravity separation process. The specific steps are as follows:

[0024] 1) Pre-grading + closed-circuit grinding process

[0025] Feed the crushed product with a particle size of 12-0mm into the wet single-layer vibrating screen to obtain the on-screen product and the under-screen product, and the +1mm on-screen product with a yield of 70% is fed into the first stage of cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com