New silicon-aluminum-barium-calcium multicomponent deoxidation alloy for steelmaking and preparation technology thereof

A silicon-aluminum-barium-calcium, deoxidation alloy technology, applied in the field of deoxidation in steelmaking, can solve the problems of unsatisfactory deoxidation effect and economic benefits, high production cost, complicated process, etc., and achieve high specificity, low melting point and improved comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

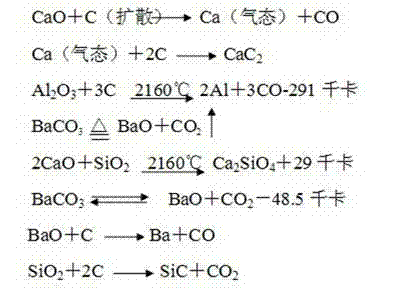

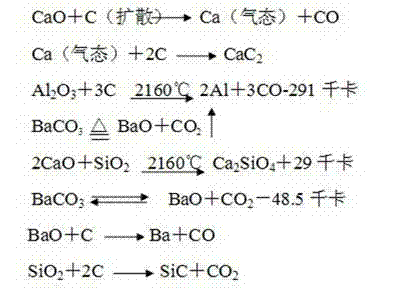

Method used

Image

Examples

Embodiment 1

[0030] The novel silicon-aluminum-barium-calcium multi-element deoxidation alloy for steelmaking of the present invention is made by smelting quartz sand, barium carbonate, lime, smelted aluminum ore and silicon carbide in an electric arc furnace, and its weight percentages are respectively: quartz sand 24 %, barium carbonate 16%, lime 16%, slaked aluminum ore 24%, silicon carbide 20%.

[0031] The preparation process is as follows: after the above-mentioned raw materials are accurately weighed according to the proportion and mixed evenly, the mixed materials are sequentially added to the electric arc furnace lined with carbonaceous electrodes. When the heating temperature reaches 1500-1600 °C, the mixed raw materials Fully react and gradually melt. After the mixture is completely melted, refine for 50-60 minutes to obtain a new liquid silicon-aluminum-barium-calcium multi-deoxidation alloy. Pour the liquid deoxidation alloy into the ingot mold to cool, and break it into pieces...

Embodiment 2

[0035] The novel silicon-aluminum-barium-calcium multi-element deoxidation alloy for steelmaking described in the present invention is made by smelting quartz sand, barium carbonate, lime, slaked aluminum ore, and silicon carbide in an electric arc furnace, and its weight percentages are respectively: quartz sand 26 %, barium carbonate 16%, lime 15%, slaked aluminum ore 22%, silicon carbide 21%.

[0036] Its preparation method is with embodiment 1.

[0037] The power consumption of new silicon aluminum barium calcium deoxidized alloy produced by submerged arc furnace is 10000~12000KW.h / t, while the power consumption of new silicon aluminum barium calcium deoxidized alloy produced by this method is as low as 2500KW.h / t, saving electricity per ton 8500KW.h.

Embodiment 3

[0039] The novel silicon-aluminum-barium-calcium multi-element deoxidation alloy for steelmaking of the present invention is made by smelting quartz sand, barium carbonate, lime, smelted aluminum ore, and silicon carbide in an electric arc furnace, and its weight percentages are respectively: quartz sand 25 %, barium carbonate 16%, lime 15%, slaked aluminum ore 21%, silicon carbide 23%.

[0040] Its preparation method is with embodiment 1.

[0041] The power consumption of new silicon aluminum barium calcium deoxidized alloy produced by submerged arc furnace is 10000~12000KW.h / t, while the power consumption of new silicon aluminum barium calcium deoxidized alloy produced by this method is as low as 3000KW.h / t, saving electricity per ton 8000KW.h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com