Superhydrophobic anticorrosive coating for marine concrete and preparation method thereof

A technology of marine concrete and anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high durability and weather resistance and long-term anti-corrosion, poor adhesion of concrete substrates, insufficient superhydrophobic stability, etc., to prevent ultraviolet rays Effects of penetration, reduction of surface energy, and enhancement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

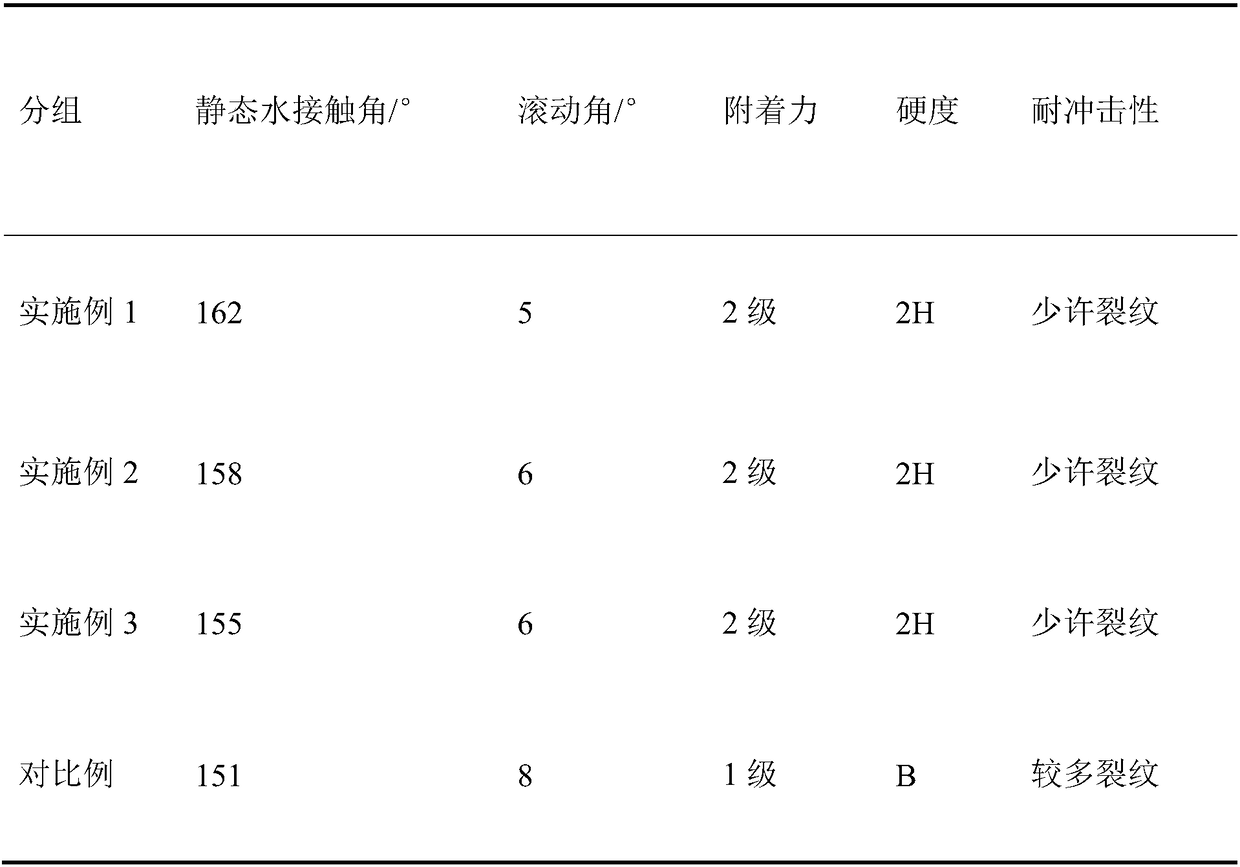

Examples

Embodiment 1

[0025] A super-hydrophobic anti-corrosion coating for marine concrete, which is prepared from the following raw materials in parts by weight: 70 parts of modified silicon-acrylic emulsion, 1.5 parts of ethyl orthosilicate, 5 parts of methyl triethoxysilane, 35 parts of ethanol and 0.8 parts of 2-amino-2-methyl-1-propanol and 8 parts of ammonia water.

[0026] Described modified silicone acrylic emulsion is made by following steps:

[0027] 1) Add 70 parts of micro-nano sericite powder to 75 parts of absolute ethanol, and ultrasonically disperse for 0.5 h to obtain an alcohol solution; dilute the silane coupling agent with 45 parts of distilled water and 8 parts of absolute ethanol, and stir evenly until The silane coupling agent is completely hydrolyzed to obtain the hydrolyzate of the silane coupling agent; add the alcohol solution and the hydrolyzate of the silane coupling agent to the flask, mix well, add 0.8 parts of oxalic acid and 0.8 parts of NaOH solution, the temperat...

Embodiment 2

[0039] A super-hydrophobic anti-corrosion coating for marine concrete, which is prepared from the following raw materials in parts by weight: 60 parts of modified silicone acrylic emulsion, 2 parts of ethyl orthosilicate, 6 parts of methyl triethoxysilane, 40 parts of ethanol and 0.5 parts of 2-amino-2-methyl-1-propanol and 10 parts of ammonia water.

[0040] Described modified silicone acrylic emulsion is made by following steps:

[0041] 1) Add 60 parts of micro-nano sericite powder to 80 parts of absolute ethanol, and disperse by ultrasonic wave for 0.5h to obtain an alcohol solution; dilute the silane coupling agent with 50 parts of distilled water and 5 parts of absolute ethanol, and stir evenly until The silane coupling agent is completely hydrolyzed to obtain the hydrolyzate of the silane coupling agent; add the alcohol solution and the hydrolyzate of the silane coupling agent to the flask, mix well, add 1 part of oxalic acid and 0.5 part of NaOH solution, the temperatu...

Embodiment 3

[0052] A super-hydrophobic anti-corrosion coating for marine concrete, which is prepared from the following raw materials in parts by weight: 80 parts of modified silicone acrylic emulsion, 1 part of ethyl orthosilicate, 4 parts of methyl triethoxysilane, 30 parts of ethanol 1 part and 1 part of 2-amino-2-methyl-1-propanol and 5 parts of ammonia water.

[0053] Described modified silicone acrylic emulsion is made by following steps:

[0054] 1) Add 80 parts of micro-nano sericite powder to 70 parts of absolute ethanol, and ultrasonically disperse for 0.5 h to obtain an alcohol solution; dilute the silane coupling agent with 40 parts of distilled water and 10 parts of absolute ethanol, and stir evenly until The silane coupling agent is completely hydrolyzed to obtain the hydrolyzate of the silane coupling agent; add the alcohol solution and the hydrolyzate of the silane coupling agent to the flask, mix well, add 0.5 part of oxalic acid and 1 part of NaOH solution, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com