Glass-fiber-reinforced flame-retardant polycarbonate composite material, and preparation method and applications thereof

A technology of flame-retardant polycarbonate and glass fiber, applied in the field of engineering plastics, can solve problems affecting impact toughness, low-temperature impact resistance, unfavorable material flame-retardant properties, etc., to achieve improved compatibility, strong hydrolysis resistance, and excellent low temperature The effect of impact resistance

Inactive Publication Date: 2019-08-23

SHENZHEN HALCYON NEW MATERIALS

View PDF13 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the flame retardant is phosphorus selenium flame retardant, by adding a certain proportion of glass fiber chopped strands, glass flakes, flame retardants and synergistic flame retardants to the polycarbonate resin, the composite material is formed The finished product not only has good flame retardancy, but also has good mechanical properties. However, the amount of phosphorus flame retardant added in this invention is too small, and the bridging effect of glass fibers will make the toughening agent easy to burn, which is not conducive to Improvement of flame retardant properties of materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 7

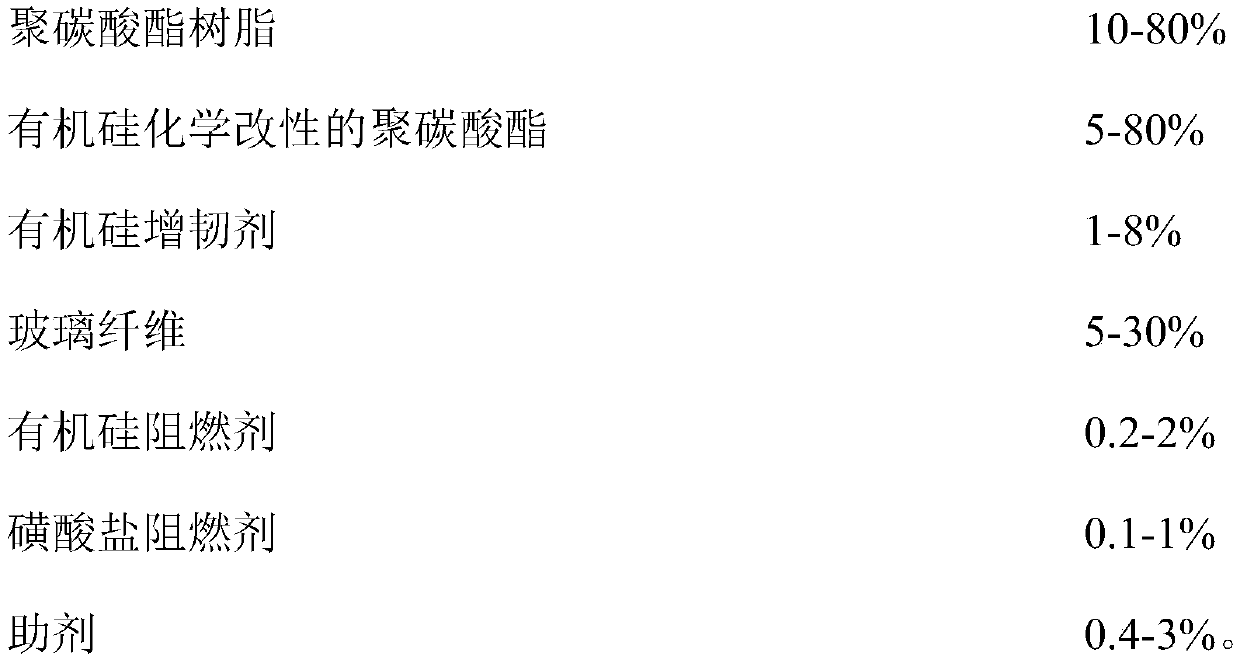

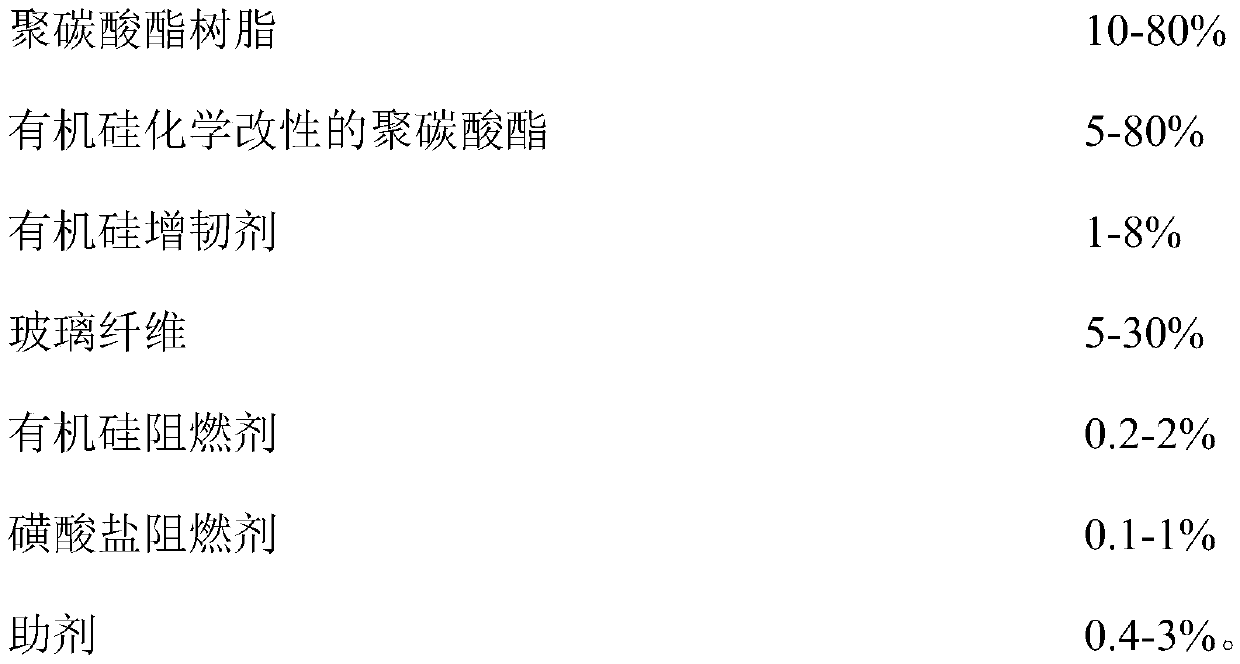

[0078] This embodiment provides a kind of polycarbonate composite material, and described composite material comprises following components according to mass percentage:

[0079]

Embodiment 8

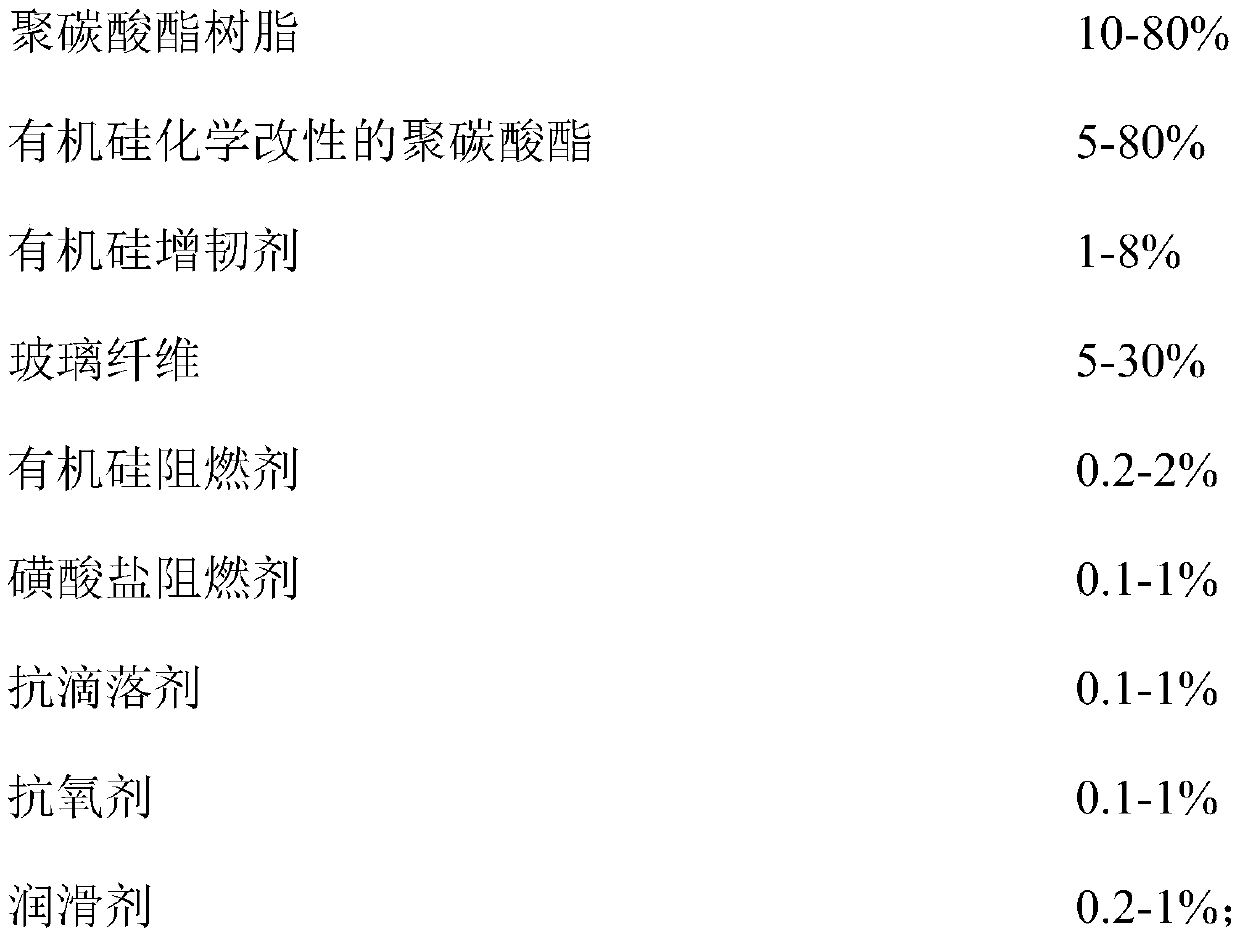

[0081] This embodiment provides a kind of polycarbonate composite material, and described composite material comprises following components according to mass percentage:

[0082]

[0083]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a glass-fiber-reinforced flame-retardant polycarbonate composite material, and a preparation method and applications thereof. The glass-fiber-reinforced flame-retardant polycarbonate composite material comprises, by mass, polycarbonate resin of 10 to 80%, silicone chemically modified polycarbonate of 5 to 80%, silicone toughening agent of 1 to 8%, glass fiber of 5 to 30%,silicone flame retardant of 0.2 to 2%, sulfonate flame retardant of 0.1 to 1%, and an auxiliary agent of 0.4 to 3%. The glass-fiber-reinforced flame-retardant polycarbonate composite material possesses excellent low temperature impact resistance, flame resistance, rigidity, heat resistance, and hydrolysis resistance, contains no halogen, and is friendly to the environment.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a glass fiber-reinforced flame-retardant polycarbonate composite material and a preparation method and application thereof. Background technique [0002] Polycarbonate (English name Polycarbonate, referred to as PC), is a colorless and transparent amorphous thermoplastic polymer material. It has high strength, high toughness, high heat resistance, excellent electrical insulation, elongation, dimensional stability and chemical corrosion resistance, high heat resistance and cold resistance; it is also self-extinguishing, easy to strengthen, flame retardant , Non-toxic, hygienic, easy to color, anti-shock and other excellent properties, so the amount of PC in engineering plastics is second only to polyamide (PA) and ranks second. [0003] With the integration and development of new-generation information technologies such as mobile technology and innovative cloud compu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L69/00C08L83/10C08L83/04C08L87/00C08L27/18C08L33/12C08K13/06C08K7/14C08K5/42C08J5/08

CPCC08J5/08C08J2369/00C08J2427/18C08J2433/12C08J2483/04C08J2483/10C08J2487/00C08K5/42C08K7/14C08K13/06

Inventor 卢其勇

Owner SHENZHEN HALCYON NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com